ACS, IT, and OT in Industrial Control Systems

Explore the distinctions between ACS, IT, and OT in industrial settings. Learn how these systems play crucial roles in ensuring safety, efficiency, and cybersecurity within enterprises. Discover the unique characteristics and considerations associated with each of these technologies.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

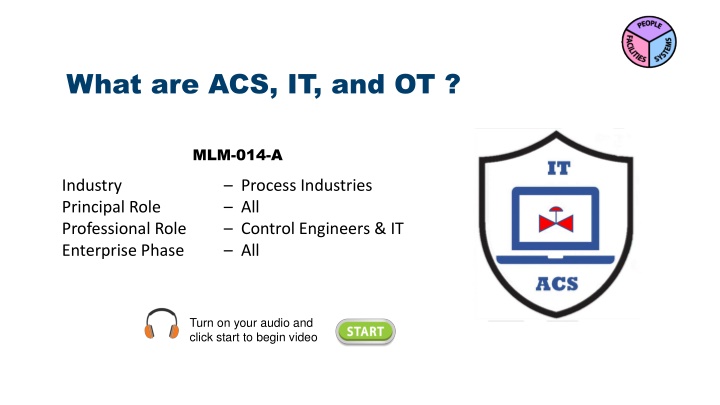

What are ACS, IT, and OT ? MLM-014-A Industry Principal Role Professional Role Enterprise Phase Process Industries All Control Engineers & IT All Turn on your audio and click start to begin video

Foundation Definitions Control and Information Architectures may include: IT Information Technology Systems OT Operational Technology devices and networks ACS Automation and Control System Networks to communicate within and between IT and ACS systems, Enterprise Architecture IT OT ACS 2

Why Distinguish IT and ACS? Because they are fundamentally different: 1) Secure ACS must be designed in .They cannot be bolted on or evolved as needed . 2) ACS must prioritize safety. They are intimately involved in equipment regulatory control. 3) ACS failures are more dangerous than IT failures. IT failures result in financial loss, while an ACS directly impacts facilities, the environment, and human life. 4) Cybersecurity of IT systems and ACS have different goals. IT Confidentiality, Integrity, and Availability vs. ACS - Safety, Availability, Integrity, and Confidentiality. 5) IT and ACS are at different levels in the Enterprise Architecture. 3

Information Technology (IT) IT consists of Business Systems + Cloud + IoT Business systems consist of a set of applications that receive manual and real- time data, and process this to provide results, reports, and displays to humans and other systems. Cloud computing applications run on Internet servers and deliver data to Business Systems IT Cloud IoT devices and networks may gather real-time edge data and deliver this to Business Systems via the Internet. Business Systems IoT PLANT FIREWALL(S)

Automation & Control Systems (ACS) ACS include ICS + IAS + IIoT + Plant Firewalls Each of these requires the skills and experience of Control Engineers to design and maintain. ICS, IAS, and IIoT devices and networks should not be directly connected to each other. PLANT ACS include plant Firewalls that connect ACS networks to Business Systems. FIREWALL(S) IAS Robotic s & Discrete ICS DCS, PLC & SCADA IIoT ACS

What does this look like in a Process Industry Architecture 6

Working Definition of Operational Technology (OT)? There are several working definitions of the Operational Technology (OT) term, including: 1)Any computer system at a production facility (resulting in confusion between the definition of both IT and ACS) 2)Any computer system connected to plant equipment (resulting in confusion between the role of IT and ACS personnel) 3)Any computer system having IT and ACS systems and networks working together in real-time 7

PERA Definition of OT (Operational Technology) Any computer system having IT and ACS systems and networks working together in real-time Option 3 was selected for PERA because: It establishes where OT fits in the Enterprise architecture (in both IT and ACS areas) It clarifies responsible roles (both IT and ACS have roles, with the lead decided by Operations or Project Management). It is consistent with the original Gartner 2006 definition of OT (with clarifications that are described in MLM-014-B). 8

PERA Operational Technology Concepts IT DATA ANALYSIS STORAGE & PRESENTATION Presents Information OT Controls through ACS PLANT FIREWALL(S) ACS ACS PROCESSING & CONTROL ACTIONs Takes Automated Actions 9

IT, IACS, and OT Architecture and Human Skills Required 10

Key Take-away Messages 1. ACS = ICS + IAS + IIoT + Firewalls. In 2005, ISA 62443 defined the term Industrial Automation and Control Systems (or IACS) to define what this international IEC and ISA standard addresses. ISA62443 was first applied in process industries but was also intended for non-industrial sectors. Accordingly, the IACS name was changed to ACS (deleting the industrial adjective). In every sector, ACS requires the skills and experience of Control Engineers for both safety and cybersecurity. Designing and supporting an ACS requires deep knowledge of the equipment, processes, and priorities in that sector. 11

Key Take-away Messages 2. IT = Business Systems + Cloud + IoT. Does not control equipment. Uses corporate IT infrastructure. 3. OT = Operational Technology. Gartner defined this term in 2006 for power utilities, then expanded it to other industries. May use corporate IT and/or ACS infrastructure. Control Engineers and IT specialists collaborate. 12

More Reading Related MLMs: MLM-014-A ACS, IT and OT Definitions MLM-014-C What are Cloud, IoT and IIoT Systems MLM-014-D When to use Cloud, IoT and IIoT Systems MLM-034-A Cybersecure IT and ACS Interfacing 3d Party References ISA 62443-1-1 Concepts and Models 13

Author Gary has more than 40 years of experience with enterprise integration and optimization projects, including PERA master planning and project management. As one of the initial authors of the PERA Handbook of Master Planning, he has used PERA Enterprise Architecture and Master Planning methodologies throughout his career including control and information systems for oil production, pipelines, refining and marine loading, petrochemicals, coal, gas, and oil-fired power plants, polyethylene, ammonia, explosives, paint, pulp and paper, food and beverage, and pharmaceuticals. LNG facilities included world-scale arctic, European, and US Gulf coast complexes. infrastructure facilities included Fire, Police, and Emergency Response systems for major US cities, as well as emissions reporting and trading systems for more than 100 US Power Plants, https://creativecommons.org/licenses/by-sa/4.0/ Please click here to provide feedback on this MLM. 14