Advanced Machinery Vibration Assessment System

Focus on advanced machinery vibration assessment through low-cost sensors, motion visualization, image processing, and AI for fault diagnosis in Condition Based Maintenance. Utilizes MEMS sensors and machine learning techniques to effectively visualize, diagnose, and classify common machinery faults. Implement in current maintenance programs for improved efficiency.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

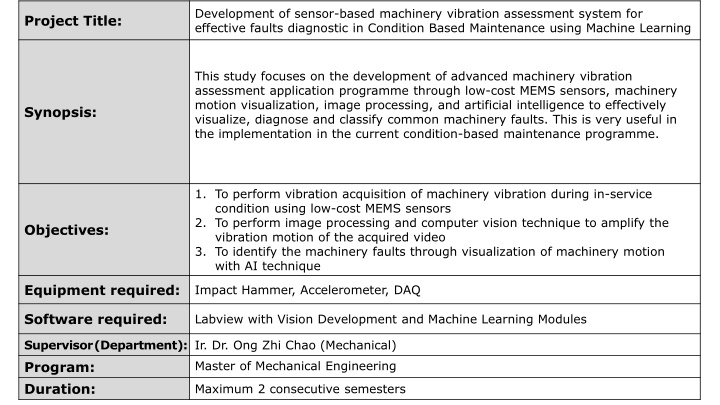

Development of sensor-based machinery vibration assessment system for effective faults diagnostic in Condition Based Maintenance using Machine Learning Project Title: This study focuses on the development of advanced machinery vibration assessment application programme through low-cost MEMS sensors, machinery motion visualization, image processing, and artificial intelligence to effectively visualize, diagnose and classify common machinery faults. This is very useful in the implementation in the current condition-based maintenance programme. Synopsis: 1. To perform vibration acquisition of machinery vibration during in-service condition using low-cost MEMS sensors 2. To perform image processing and computer vision technique to amplify the vibration motion of the acquired video 3. To identify the machinery faults through visualization of machinery motion with AI technique Objectives: Equipment required: Impact Hammer, Accelerometer, DAQ Software required: Labview with Vision Development and Machine Learning Modules Supervisor(Department): Ir. Dr. Ong Zhi Chao (Mechanical) Program: Master of Mechanical Engineering Duration: Maximum 2 consecutive semesters

Design and development of Piezoelectric Vibration Energy Harvester system with optimized performance Project Title: This study focuses on the design, analysis, fabrication and testing of piezoelectric vibration energy harvester system which considers the vibration aspect to harvest optimal energy from low and wide frequency range of vibrating system. This study also deals with proposing a new optimum design configuration of vibration energy harvester via computational assessments and experimental validation. Synopsis: 1. To design a piezoelectric vibration energy harvester system based on vibration aspect 2. To improve the performance of piezoelectric energy harvesting bimorph plate via design modification 3. To validate experimentally the proposed design on the performance enhancement of piezoelectric energy harvesting bimorph plate Objectives: Equipment required: Electromagnetic Shaker System with Power Amplifier, DAQ Software required: Solidworks, ANSYS, Data acquisition program Supervisor(Department): Ir. Dr. Ong Zhi Chao (Mechanical) Program: Master of Mechanical Engineering Duration: Maximum 2 consecutive semesters

Enhancement of energy harvesting performance by omni-directional wind funnel coupled with optimal bluff splitter body design Project Title: This study focuses on the design and development of an omni-directional wind funnel which will be installed in front of the coupled bluff splitter body and PVEH plate to fulfil the task of energy harvesting. The omni-directional wind funnel is able direct winds from multiple directions to an optimum wind speed range before channelling it to the adopted optimum aspect ratio, shape and angle design of coupled bluff splitter body and PVEH plate. By generating optimum vortex frequency according to the characteristics of the PVEH plate, maximum energy output is expected. Synopsis: 1. To design omni-directional wind funnel for the optimized design of coupled bluff splitter body and PVEH plate 2. To investigate the vortex induced vibration performance enhancement using the omni-directional wind funnel coupled with optimal bluff splitter body 3. To perform design optimization on the mini-direction wind funnel Objectives: Equipment required: N/A Software required: Solidworks, ANSYS Supervisor(Department): Ir. Dr. Ong Zhi Chao (Mechanical) Program: Master of Mechanical Engineering Duration: Maximum 2 consecutive semesters

Project Title: Development of a sensor-based monitoring system for post-COVID recovery The proposed system would employ an Internet of Things (IoTs) framework to collect real-time long covid symptom data from users to monitor the treatment response of those who have already recovered from the virus, and to understand the nature of each individual recovery process by collecting and analysing relevant data. The proposed platform allows remote monitoring of any long covid symptoms and virtual assessments which can drastically reduce the congestion in various healthcare units. This can be useful for recovered patients, health institutes and researchers. Synopsis: 1. To develop an IoT based wearable sensors infrastructure for long covid patients remote monitoring 2. To develop cloud-based framework integrating communication between IoT sensors infrastructure and web frontend layer 3. To assess the sensors data for long covid symptoms through virtual assessments Objectives: Equipment required: Biosensors, Microprocessors with wireless module Software required: Arduino, MATLAB, IoT based visualization and analytics software Supervisor(Department): Program: Duration: Ir. Dr. Ong Zhi Chao (Mechanical) Master of Mechanical Engineering Maximum 2 consecutive semesters

Development of acoustic measurement and analysis application program for noise risk assessments Project Title: This study focuses on the development of advanced acoustic measurement and analysis application programme which has the functions of acquire, monitor, analyse noise data using virtual instrument for noise risk assessments. The assessments include the noise contour mapping, noise source localization and sound power determination. This will be noise control and insulation measures for facilities, equipment, working areas at workplace. Synopsis: 1. To develop a sound measurement system for real time sound pressure and intensity acquisition 2. To develop a monitoring and analysis tool for noise mapping, noise source localization and sound power determination. 3. To compare with commercial measurement system Objectives: Equipment required: Sound Level Meter, Sound Intensity Probe Kit, DAQ Software required: Labview Supervisor(Department): Program: Duration: Ir. Dr. Ong Zhi Chao (Mechanical) Master of Mechanical Engineering Maximum 2 consecutive semesters

Development of the digital twin model of robotic arms for virtual control and monitoring Project Title: This study focuses on the development of two-way connectivity digital twin model of a robotic arms which build a complete virtual prototype to accurately reflect the physical robotic arms. The embedded physical sensors at robotic arms can be used for real time monitoring in digital twin model. More virtual sensors nodes can also be created for full performance analysis of the robotic arms in which the outcomes of the analysis results can be used to control the robotic arms physically. Synopsis: 1. To develop real to virtual digital twin model for real time monitoring of robotic arms parameters from embedded sensors. 2. To perform full performance analysis of the robotic arms using the extended inexpensive virtual sensor nodes from the digital twin model 3. To develop virtual to real digital twin model to control the physical robotic arms virtually based on the virtual monitoring and analysis data Objectives: Equipment required: Low-cost miniature robotic arms Software required: 3DEXPERIENCE, ANSYS Twin Builder Supervisor(Department): Program: Duration: Ir. Dr. Ong Zhi Chao (Mechanical) Master of Mechanical Engineering Maximum 2 consecutive semesters