Advanced Sensor Technology Overview

Explore the latest advancements in sensor technology for BeamCal applications, including requirements for compactness and radiation hardness. Learn about sensor materials like Sapphire, Diamond, GaAs, and Si, with detailed properties and performance under irradiation. Discover insights from Bruce Schumm on sensor dosages and annealing effects, along with characteristics of GaAs sensors under electron irradiation. Gain knowledge on irradiation effects on single crystal and polycrystalline Diamond and Sapphire sensors. Stay informed on cutting-edge developments in sensor technology for high-energy physics experiments.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

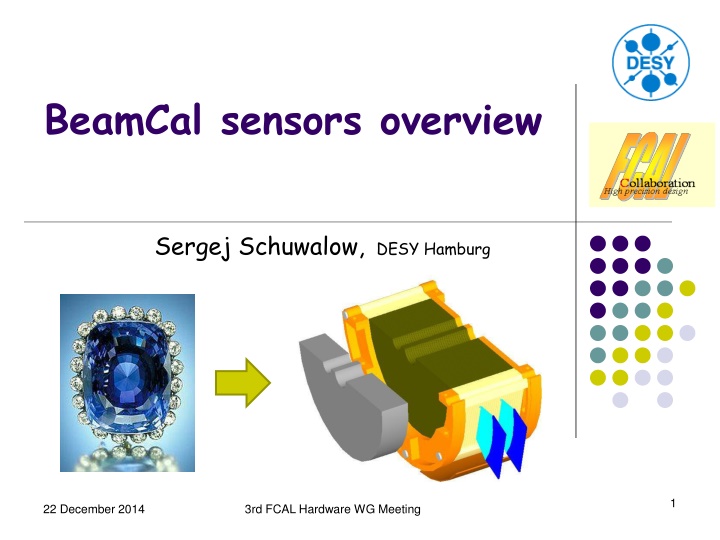

BeamCal sensors overview Sergej Schuwalow, DESY Hamburg 1 22 December 2014 3rd FCAL Hardware WG Meeting

BeamCal sensor requirements BeamCal should be compact, small Moliere radius needed: -sampling calorimeter with solid state sensors, tungsten as absorber. Severe load at small radii due to beamstrahlung: - radiation hard sensors (up to 1 MGy annual dose) Bunch-by-bunch operation: - fast response of sensors Test beam studies, physical calibration: - sensitivity to MIPs 22 December 2014 3rd FCAL Hardware WG Meeting 2

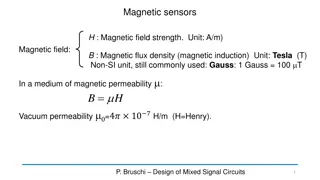

Sensor material properties Sapphire Diamond GaAs Si Density, g/cm3 3.98 3.52 5.32 2.33 Dielectric constant 9.3 11.5 5.7 10.9 11.7 Breakdown field, V/cm ~106 * 107 4.105 3.105 Resistivity, cm >1014 >1011 Band gap, eV 9.9 5.45 1.42 1.12 El. mobility, cm2/(V s) >600 ** 1800 ~8500 1360 Hole mobility, cm2/(V s) - 1200 - 460 MIP eh pairs created, eh/ m 22 107 105 36 150 73 * Typical operation field ~1-2 104 V cm-1 ** at 20 C, ~30000 at 40 K 22 December 2014 3rd FCAL Hardware WG Meeting 3

Radiation Hardness 22 December 2014 3rd FCAL Hardware WG Meeting 4

Bruce Schumm, 25th FCAL WS Results: PF sensors Doses of 5 and 20 Mrad No annealing 5

Bruce Schumm, 25th FCAL WS Results: NC sensors Dose of 220 Mrad Incidental annealing ~15% charge loss at 300 ns shaping 6

Irradiation of GaAs sensors 10 MeV electrons Few A leakage current after 1 MGy dose (extra noise!) 22 December 2014 3rd FCAL Hardware WG Meeting 7

Irradiation of sapphire and diamond sensors at ~10 MeV electron beam Single crystal CVD diamond Single crystal sapphire 100% CCE 10% CCE Leakage current after irradiation is still at few pA level 10 MGy ~ 5.1016 MIPs ~ 2.5.1015 [1 MeV neq] (NIEL,Summers) 22 December 2014 3rd FCAL Hardware WG Meeting 8

Irradiation of sapphire and diamond sensors at ~10 MeV electron beam Polycrystalline CVD diamond Single crystal sapphire ~60% CCE pumping Depumping by UV Leakage current after irradiation is still at few pA level 10 MGy ~ 5.1016 MIPs ~ 2.5.1015 [1 MeV neq] (NIEL,Summers) 22 December 2014 3rd FCAL Hardware WG Meeting 9

BeamCal design 22 December 2014 3rd FCAL Hardware WG Meeting 10

Baseline design 30 layers (3.5 mm W + 0.5 mm sensor*) Rin = 20 mm, Rout(sens)=150 mm Sensor material - GaAs Sensor prototype: Wafer size 74 mm eff. diameter Thickness 500 m (thinner problematic) 2 rings of sensors (GaAs + Si for outer?) Thin fanout PCB (Hans), bonding (2 options) Cost ~650 Euro/pc (312kE/Calorimeter, even if only inner ring is made out of GaAs) 22 December 2014 3rd FCAL Hardware WG Meeting 11

Modification of BeamCal design for sapphire sensors application 22 December 2014 3rd FCAL Hardware WG Meeting 12

Dynamic range needed for BeamCal Readout (high energy electrons/MIPs) 200 GeV electrons 200 GeV electrons MIPs MIPs Factor ~2300 Factor ~220 22 December 2014 3rd FCAL Hardware WG Meeting 13

BeamCal energy resolution 200 GeV electrons, GEANT3 Monte Carlo New design Baseline design. E/E = 1.6% New design E/E ~ 8% Response nonuniformity in the direction, perpendicular to the strips, depends on relative layer positioning. Further optimization is needed. 22 December 2014 3rd FCAL Hardware WG Meeting 14

Plans Prepare 4 GaAs sensor planes for the next test beam Sapphire sensors: detailed BeamCal design, MC studies Develop sapphire wafers quality control (UV + visible light?) New design BeamCal prototype, based on sapphire sensors Test beam studies Manpower? Resources? 22 December 2014 3rd FCAL Hardware WG Meeting 15