Advanced Technology Readiness Assessment in Manufacturing Process Development

A comprehensive Technology Readiness Assessment (TRA) at TRL 6 or greater has been conducted for manufacturing process development. Key milestones include industrial base capabilities assessment, supplier management policy implementation, justification for sole/source needs, demonstrative manufacturing technology solutions, producibility assessments, preliminary design assessments against capability constraints, and cost modeling updates. Additionally, a system allocated baseline has been established, product requirements defined for Preliminary Design Review support, critical technologies demonstrated, and cost strategies developed. The program is on track to achieve MRL 8 by Milestone C with reasonable budget estimates.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

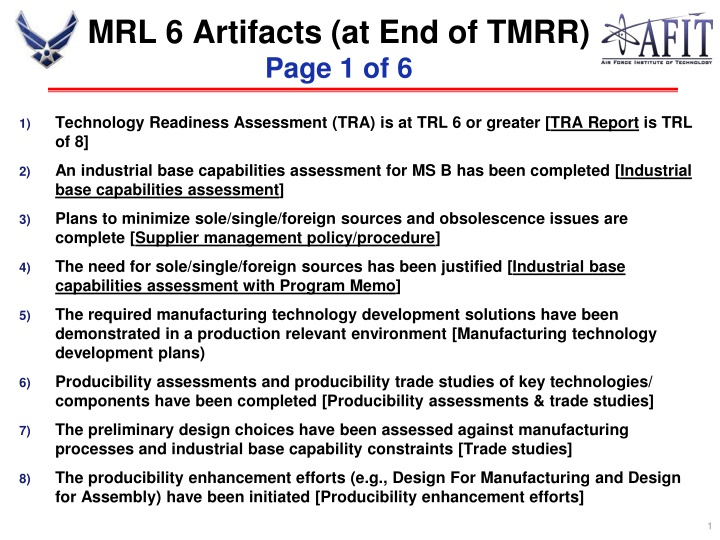

MRL 6 Artifacts (at End of TMRR) Page 1 of 6 Technology Readiness Assessment (TRA) is at TRL 6 or greater [TRA Report is TRL of 8] 1) An industrial base capabilities assessment for MS B has been completed [Industrial base capabilities assessment] 2) Plans to minimize sole/single/foreign sources and obsolescence issues are complete [Supplier management policy/procedure] 3) The need for sole/single/foreign sources has been justified [Industrial base capabilities assessment with Program Memo] 4) The required manufacturing technology development solutions have been demonstrated in a production relevant environment [Manufacturing technology development plans) 5) Producibility assessments and producibility trade studies of key technologies/ components have been completed [Producibility assessments & trade studies] 6) The preliminary design choices have been assessed against manufacturing processes and industrial base capability constraints [Trade studies] 7) The producibility enhancement efforts (e.g., Design For Manufacturing and Design for Assembly) have been initiated [Producibility enhancement efforts] 8) 1

MRL 6 Artifacts (at End of TMRR) Page 2 of 6 A system allocated baseline has been established [System Allocated Baseline] 9) The product requirements and features are well enough defined to support Preliminary Design Review (PDR) [Defined product requirements and features] 10) Product data essential for subsystem/system prototyping has been released [Prototype product data released] 11) All enabling/critical technologies/components have been demo d [Demonstration documentation] 12) Preliminary design Key Characteristics (KC) have been defined and mitigation plans are in development [Preliminary KCs documented and mitigation plans] 13) Cost models have been updated with design requirements, material specifications, tolerances, integrated master schedule, results of system/subsystem simulations and production relevant prototype demonstrations [Cost model information] 14) Cost targets have been allocated to subsystems [Cost model information reflects subsystem cost targets] 15) 2

MRL 6 Artifacts (at End of TMRR) Page 3 of 6 Cost reduction and avoidance strategies have been developed [Cost reduction and avoidance strategies] 16) Manufacturing cost drivers are included in "Should-Cost" models ["Should-Cost" model] 17) The program has a reasonable budget estimate for reaching MRL 8 by Milestone C [budget estimate] 18) The cost estimate includes capital investment for production-representative equipment by CDR and pilot line equipment by Milestone C [cost estimate includes capital investment] 19) All outstanding MRL 6 risk areas are understood with approved mitigation plans in place [approved mitigation plans] 20) Material maturity has been verified with technology demonstration articles [verification documentation] 21) Preliminary material specifications are in place [material specifications] 22) All material properties have been adequately characterized [material properties characterization documented] 23) 3

MRL 6 Artifacts (at End of TMRR) Page 4 of 6 Material availability issues have been addressed to meet Engineering and Manufacturing Development (EMD) build [Material availability issues documentation] 24. Long-lead items have been identified [Long-lead items documentation] 25. Potential obsolescence issues have been identified [Obsolescence/DMSMS plans/documentation] 26. Components have been assessed for future DMSMS risk [Obsolescence/DMSMS plans/documentation] 27. Life cycle supply chain requirements and the critical suppliers list has been updated [Program supply chain list] 28. Supply chain plans (e.g., teaming agreements, etc.) are in place for an EMD contract award [Supply chain policies/procedures and contracts/Purchase Orders (POs)] 29. Special handling procedures have been applied in a production relevant environment [Special handling procedures documented Technical Data, Work Instructions, etc.] 30. Plans to address the special handling requirement gaps have been completed [special handling requirement procedures plan/documentation] 31. 4

MRL 6 Artifacts (at End of TMRR) Page 5 of 6 Initial simulation models have been developed at the technology sub-system or system level and used to determine system constraints [simulation models] 32. Key manufacturing processes have been demonstrated in a production relevant environment [demonstration documented] 33. Process capability requirements have been refined [Process capability requirements documented] 34. Yields and rates from the production relevant environment has been evaluated against targets [Yields and rates and targets documented] 35. There is an initial Quality Plan (QP) and a Quality Management System (QMS) in place [Quality Plan and a Quality Management System documented] 36. A Key Characteristic management approach has been defined [Key Characteristic management policy/procedure documented] 37. Initial requirements have been identified for acceptance test procedures and in- process and final inspection requirements for EMD units [acceptance test procedures and in-process and final inspections documentation] 38. 5

MRL 6 Artifacts (at End of TMRR) Page 6 of 6 Appropriate inspection and acceptance test procedures have been identified for prototype units [acceptance test procedures and in-process and final inspections documentation] 39. Manufacturing workforce skills are available for production in a relevant environment [Manufacturing workforce skills documented employee & personnel training records] 40. A workforce resources plan (quantities and skill sets) has been identified to achieve requirements for pilot line and production [Manufacturing workforce resource plan employee & personnel training records] 41. Prototype tooling and STE/SIE concepts have been demonstrated in production relevant environment [Prototype tooling and STE/SIE concepts demonstration documentation] 42. Manufacturing facilities and plans have been identified to produce the pilot line build [Manufacturing plan] 43. A manufacturing risk mitigation approach for the pilot line or technology insertion programs has been defined [documented program risk process] 44. Material risk mitigation plans have been developed [risk mitigation plans & MMPs] 45. The Bill of Materials (BOM) has been initiated [BOM documentation] 46. 6