Advantages and Maintenance of Anti-Friction Bearings in Industrial Machinery

Discover the advantages of anti-friction bearings, including space efficiency, speed limitations, warning signals, and more. Learn maintenance tips to prevent overheating due to lubrication issues. Find solutions for common reasons and indicators of bearing problems in machinery operations.

Uploaded on | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

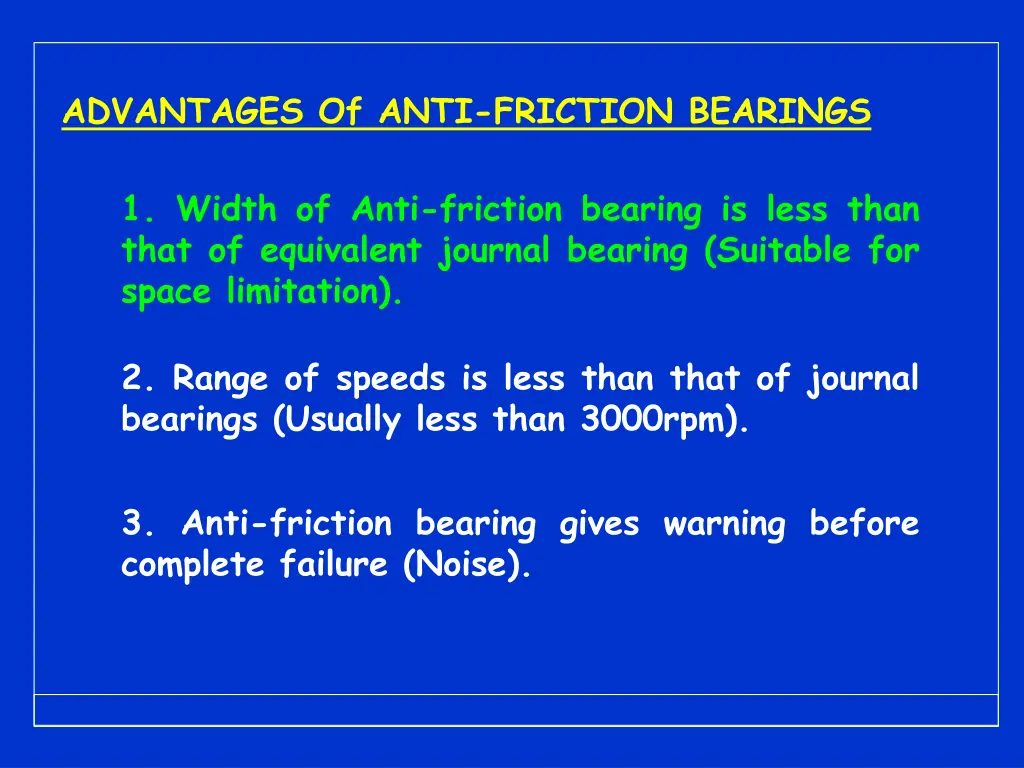

ADVANTAGES Of ANTI-FRICTION BEARINGS 1. Width of Anti-friction bearing is less than that of equivalent journal bearing (Suitable for space limitation). 2. Range of speeds is less than that of journal bearings (Usually less than 3000rpm). 3. Anti-friction bearing gives warning before complete failure (Noise).

4. clearances). Higher assembly accuracy (i.e. small 5. Anti-friction bearing can be pre-lubricated (Z and ZZ series). 6. Manufacturers provide the market with at least three sizes for each shaft diameter.

MAINTENANCE RECOMMENDATION

1. OVERHEATING: Heating of a bearing is the description of the temperature of the bearing if it is above the ambient temperature with 20OC to 30OC. Overheating describes the condition of bearing temperature when the temperature increases over 70OC (Service temperature). Any temperature reading above this level should be a cause for close inspection until the problem is located and corrected.

REASONS Of OVERHEATING Finding of bearing overheating is the job of the Maintenance personal or workplace-operator. Bearing overheating can be due to: 1- Incorrect Lubrication system. 2- Improbable instillation Process. 3- Overloading or/and unconsidered Loading component. 4- Misalignment.

A. Lubrication Lubrication problems can be due to one or more of the following: 1- Wrong type of lubricant. 2- Insufficient lubricant flow. 3- Excessive lubricant. 4- Contamination. 5- Insufficient lubricant change.

WRONG Type Of Lubricant -Wrong type of lubricant is one of the most difficult problems because overheating takes place while seals and lubricant level appear in good conditions. -Therefore, the single way to determine if the lubricant is wrong is the continuous recording of temperature of the bearing.

-For example, if the bearing is just installed and overheating is recorded at the running-in period, this means that overheating is due to the initial contact of some new surfaces, which tends to increase the temperature. -But, by continuous recording of the overheating in the presence of right oil level and no leakage from seals, this case means that there is problem with the lubricant it self.

The in-correct lubricant type can be due to: 1- Lower or Higher viscosity. 2- Insufficient lubricant additives. 3- Presence of contaminants in lubricant. In some cases, too high oil level can be a reason of overheating due to the energy loss in moving the oil mass (churning of lubricant). Also, too low oil level means missing of lubrication at contact points or lines between rolling elements and inner and outer races.

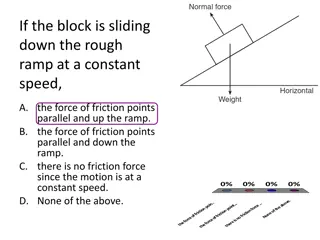

It is clear that the lubricant is supposed to build a film wedge to separate the races from the rolling elements as shown in Figure. This film cannot be formed if the lubricant is insufficient and hence metal-to-metal contact takes place. Inner Race Oil film Outer Race

B. Instillation Incorrect instillation is a reason for overheating. The sources of instillation overheating are: 1- Incorrect shaft fit. 2- Incorrect housing fit. 3- Misalignment. 4- Rubbing seals.

Incorrect shaft fit: Incorrect shaft fit means either the shaft is over- or under-size.. By over-size shaft, the inner race of the bearing should expend to be installed in the shaft. This excessive expansion geometries of the bearing to be distorted, which will be a reason for removing the necessary clearance between the rolling elements and the races. causes the internal Inner Ring Expansion Clearance Removing

If the shaft fit is under size, a relative motion will takes place between race and shaft, which tends to generate high temperature due to the power loss in friction between the two matting surfaces. Hence, heat between inner race and balls and results in film- width distorsion. reaches the oil film Inner Race Slip

Incorrect housing fit: Incorrect housing fit has essentially the opposite effect of the incorrect shaft fit. Fig. 4 shows the effect of over-tight of housing. A. Squeeze the bearing outer race. B. Removes all clearances between the balls and races.

Misalignment: Misalignment is defined as the shift of the axis of the bearing from that of the shaft. In this case wear takes place with a higher rate. The rolling element will take a path, which is different from the normal one. This will result in metal-to-metal contact (under load) in the bearing. Fig. Ball path runs from one side to the other (instead of in the middle) when the bearing is misaligned

Rubbing seals: Incorrect height of bearing shoulder tends to a contact between bearing seal and shoulder, which tends to increase the temperature of the bearing. Sealing Sealing Too High Shoulder Shoulder Correct shoulder height Incorrect shoulder height

Noise of Bearings In most cases, noise is accompanied by heat or/and vibration. But, noise inspector s attention to the bearing s problem, which can be one of the following: alone can call the 1. Loose shaft or bearing fit. 2.Tight shaft or housing. 3.Contamination. 4.Internal wear.

Loose and Tight Shaft and Housing Fit Poor housing and shaft fits cause noise as well as heat. Noise is caused by the slipping action of a loose fit. Contaminations Contaminations; that reach bearings; cause excessive noise because the contamination surface of rolling element and races as in Figure. embeds in the Contaminants Rolling Elements

It is important to notice that contamination is also possible due to incorrect handing of bearing during storage and assembly processes.

Another source of bearing contamination is the worn of the sealing element that illustrated in Figure.

It is clear that abrasive wear in rolling bearings affects both of: 1. Rolling element 2. bearing s races. The ball diameter decreases with the amount of wear while the race s diameter increases. This effect results in an increase of the clearance between rolling element and races. Balls worn smaller + Worn of Races = Clearance Increase

Also, Corrosion can be found on bearing where the damage occurs on the outer surface of the outer race and inner surface of contact of the inner race. Fig. 11 shows the corrosive damage of races. Rust Areas