Aggregate Planning Methods and Challenges in Supply Chain

Developing a preliminary schedule in aggregate planning is crucial for balancing supply and demand in the supply chain. Learn about different methods like Chase Demand and Level Production, as well as unique challenges faced in service industries.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

SELECTING THE METHOD IN AGGREGATE PLANNING AND AGGREGATE PLANNING IN SERVICES IN SUPPLY CHAIN

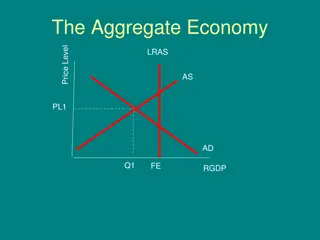

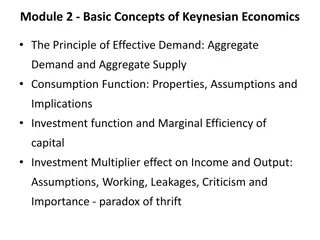

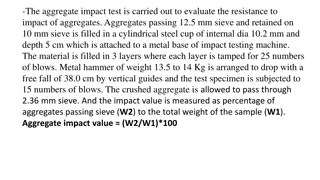

INTRODUCTION TO AGGREGATE PLANNING Definition:Aggregate planning refers to the process of developing, analyzing, and maintaining a preliminary, approximate schedule of the overall operations of an organization. Goal:To balance supply and demand, ensuring efficient resource utilization. Importance in Supply Chain: Ensures that production capacity, inventory levels, and labor resources are well- coordinated.

TYPES OF AGGREGATE PLANNING METHODS Chase Demand Strategy Adjusting production and workforce to match demand. Flexible workforce required, but costly. Level Production Strategy Producing at a constant rate, maintaining inventory to meet demand fluctuations. Useful for stable demand, minimizes labor costs. Hybrid Strategy Combines chase demand and level production strategies. Balances production cost and inventory levels.

SELECTING THE BEST AGGREGATE PLANNING METHOD Factors to Consider: Demand Variability: Choose chase demand if demand fluctuates greatly. Cost Efficiency: Level production can be more cost-efficient with stable demand. Workforce Flexibility: Chase demand requires more flexible labor. Inventory Costs: Level production may incur higher storage costs.

AGGREGATE PLANNING IN SERVICES Unique Characteristics of Service Industry: Intangibility: No physical products to inventory. Simultaneous Production and Consumption: Services cannot be stored. Demand Uncertainty: Service demand can be volatile. Service Sector Aggregate Planning Approaches: Capacity Management:Adjusting service capacity to meet fluctuating demand. Queue Management: Managing waiting times and service capacity. Flexible Workforce: Hiring temporary staff based on demand peaks.

CHALLENGES IN SERVICE AGGREGATE PLANNING Demand Forecasting: More difficult due to the intangible nature of services. Customer Behavior: Unpredictable demand patterns based on external factors (seasonality, trends). Managing Service Level Expectations: Balancing service quality with resource availability. Staffing Flexibility: Hiring or scaling staff for fluctuating service demand.

KEY AGGREGATE PLANNING TOOLS IN SERVICE INDUSTRY Capacity Planning: Estimating demand for services and adjusting capacity accordingly. Yield Management:Adjusting prices to manage demand and optimize resources. Workforce Scheduling: Creating flexible shift schedules to match demand fluctuations.

CASE STUDY: AGGREGATE PLANNING IN A SERVICE INDUSTRY Example:Airline Industry (Capacity Management and Yield Management)Adjusting aircraft capacity based on demand forecasts. Dynamic pricing to match demand patterns. Optimizing workforce scheduling for on-time services.

BENEFITS OF EFFECTIVE AGGREGATE PLANNING IN SERVICES Enhanced Customer Satisfaction:Timely delivery of services. Cost Efficiency: Optimizing resource use and minimizing idle time. Scalability: Better capacity planning allows businesses to scale services effectively. Improved Decision-Making: Data-driven decisions improve overall operations.

CONCLUSION Summary:Aggregate planning is essential in both manufacturing and service industries to ensure efficient operations, resource allocation, and customer satisfaction. Selecting the Right Method: Depends on factors such as demand variability, cost considerations, and workforce flexibility. Future Trends: Increasing reliance on advanced analytics and AI for demand forecasting and capacity planning.