Air Monitoring Training Overview

Discover the comprehensive training program on air monitoring for health and safety purposes, covering various detection methods, hazardous atmospheres, specific field work, environmental issues, emergency response, and more. Gain insights into detector types, calibration, field monitoring, hazardous gases, and other important topics. Be prepared to handle hazardous materials and atmospheric conditions effectively.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

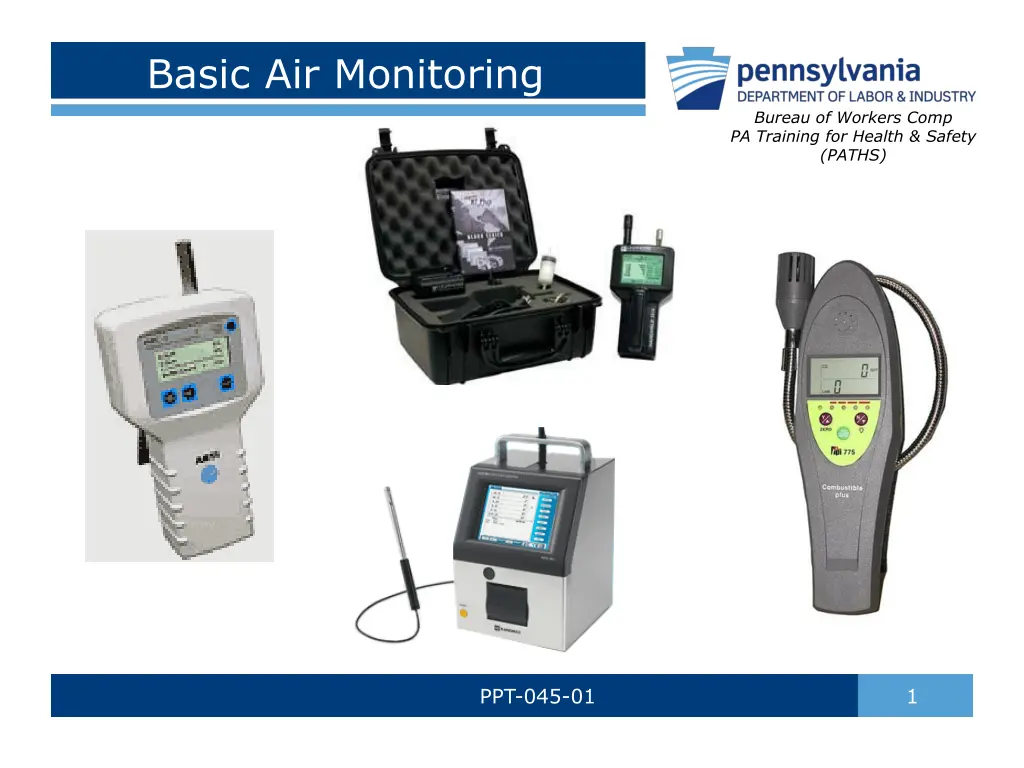

Basic Air Monitoring Bureau of Workers Comp PA Training for Health & Safety (PATHS) PPT-045-01 1

Program Purpose Various means of detection exist for solids, liquids and gases. This program is an overview of monitoring the means to be used in some safety applications or to aid in responding to an event. PPT-045-01 2

Main Topics Detector types Calibrating detectors Field monitoring Sewer entry policy as an example Working a situation Bibliography Hazards Chemical and physical properties of target materials Some gas properties Resources Propane as an example PPT-045-01 3

Hazardous Atmospheres Residential CO (carbon monoxide) Gas leaks into buildings Radon Intruding emissions from adjacent properties PPT-045-01 4

Hazardous Atmospheres Industrial Process areas Storage locations Gas leaks Flammable liquid spills Drums and containers Special activities Hazardous material events PPT-045-01 5

Municipal Operations Water treatment plants Sewer plant operations Valve pit work Garage work PPT-045-01 6

Specific Field Work Confined space Trenching and shoring PPT-045-01 7

Environmental Issues Clean air determinations Emissions control Waste sites PPT-045-01 8

Emergency Response Industrial rescue or hazardous materials response Emergency services PPT-045-01 9

Hazardous Atmospheres Special types of atmospheres Carbon monoxide LPG/LNG Radon Hydrogen sulfide Carbon dioxide Specialty gases Radiological concerns Other potential hazards PPT-045-01 10

Basic Air Monitoring Each of the previous situations could benefit from air monitoring. Detectors are generally used to determine: Oxygen content Presence of flammable vapors or gases Presence of toxic materials Terms pertaining to characteristics of materials for which monitoring might be used should be discussed first. PPT-045-01 11

Hazard Property Terms IDLH: Immediately dangerous to life and health values Exposure Limits: OSHA PEL: permissible exposure limits TWA: Time weighted average limits expressed in PPM which should not be exceeded during an 8-hour work shift in a 40-hour work week PPM: Parts per million. Can be converted into percentage by volume by dividing the PPM given by 10,000. PPT-045-01 12

Chemical & Physical Properties MW: Molecular weight will help you determine if the vapor or gas is heavier or lighter than air; the vapor density. Vapor density can be determined by dividing the material s molecular weight by 29: MW 29 PPT-045-01 13

Vapor Density A comparison of a gas or vapor s weight to air. Air is assigned a vapor density of 1.0. Gases or vapors with a vapor density greater than 1.0 are that many times heavier than air. Gases or vapors with a vapor density less than 1.0 are lighter than air. This will help you determine if you will monitor high or low in an area to obtain a reading. May also be expressed as RGasD: relative gas density. PPT-045-01 14

Flashpoint Temperature Fl.P.: Flashpoint The lowest temperature at which vapors are produced by a liquid that, when ignited, will flash No continued combustion at this temperature Sustained burning is at the fire point (temperature above the flashpoint temperature) PPT-045-01 15

IP IP: Ionization potential in electron volts (eV) for a vapor or gas This will signify a photoionization detector may be used to detect the presence of material Lamp rating must be at or greater than IP of test gas or vapor for a precise reading PPT-045-01 16

Hazard Characteristics Before starting, fully understand the hazards of the material for which you ll monitor: Vapor density Flammable limits Health hazards Exposure limits Signs and symptoms of exposure PPT-045-01 17

RGasD RGasD: Relative gas density will indicate if gas/vapor is heavier or lighter than air If we divide the MW by 29 (the weight of air) this should also approximate the vapor density of the gas/vapor PPT-045-01 18

Gas/Vapor Behavior Gases can stratify in air based on their vapor density Take readings from various depths and points in below-grade situations You may need to take readings in rooms at different elevations and points as well PPT-045-01 19

LEL/UEL UEL/LEL: Upper and lower explosive limit Range in between is the flammable range Safety Rule of Thumb Monitor until you find 10 percent of the LEL inside a building Outside: stop when you determine 20 percent LEL is evident PPT-045-01 20

UEL/LEL Will aid in determining the perimeter and extent of gas/vapor spread (100 percent of LEL, dangerous) Only ignition source needed to ignite gas/vapor You do not want to be within a flammable environment! PPT-045-01 21

Respirator NIOSH Respirator recommendations assist in determining the level of needed respiratory protection depending upon the PPM (Mg/M3) for a material PPT-045-01 22

Asphyxiation Hazards Simple Asphyxiants: Displace breathable oxygen in an area (example: carbon dioxide) Chemical Asphyxiants: Bond with red blood cells and restrict the body s ability to metabolize oxygen (examples: carbon monoxide and hydrogen cyanide) PPT-045-01 23

Some Gas Particulars LEL% (10%LEL) IDLH IP Gas Carbon Monoxide PPM % in eV 12.5 1.25 1,500 .15 13.98 Hydrogen Cyanide 5.6 56 50 .005 13.6 Hydrogen Sulfide 4.3 .43 300 .03 10.46 LPG 1.9 .19 19,000 1.9 10.95 PPT-045-01 24

Carbon Monoxide IDLH PEL IP RGasD LEL UEL 1200 ppm TWA 50 ppm 14.01 eV .97 12.5% 74% PPT-045-01 25

LPG/LNG IDLH PEL IP RGasD LEL UEL Sa/SCBA 2000 PPM (10% LEL) 1000 PPM 10.95 eV 1.45 2.0 2.1% (propane) 1.9% (butane) 9.5% (propane) 8.5% (butane) 2000 PPM PPT-045-01 26

Hydrogen Sulfide IDLH 100 ppm PEL C 20 ppm* 50 ppm (10 min max peak) IP RGasD LEL UEL Sa/SCBA 100 ppm *C=ceiling level value 10.46 eV 1.19 4.0% 44.0% PPT-045-01 27

Carbon Dioxide IDLH PEL 40,000 ppm (4%) TWA 5000 ppm (.5%) 8 hours 13.77 eV 1.53 Non-flammable gas Yes IP RGasD LEL/UEL Sa/SCBA PPT-045-01 28

Carbon Dioxide CO2 % By Volume 0.5 1.0 1.5 2.0 3.0 4.0 5.0 6.0 7.0 Max Exposure Limit, Minutes Indefinite Indefinite 480 60 20 10 7 5 Less than 3 A Total Flood carbon dioxide system will displace the breathable oxygen and asphyxiate those inside Compressed Gas Assn. Handbook, 3rd Ed, page 293 PPT-045-01 29

Other Potential Hazards Caution: Many materials have several hazards associated with them. Some may be flammable and possess poisonous characteristics. Toxic and corrosive gases may be encountered. Example: Hydrogen sulfide (H2S) deadens the sense of smell and may falsely lead someone to think it has dissipated (LEL and UEL are 4 percent to 44 percent, respectively - flammable and poison). PPT-045-01 30

Specialty Gases Specialty Gases Boron trichloride Diborane Phosphine Silane Radiological Hazards Radon Industrial events PPT-045-01 31

Action Levels Assigned by policy When a given level is read, personnel are warned to take action or to leave the area 29 CFR 1910.146 for confined spaces (10 percent LEL: permit revocation) Determine action levels for gases/vapors you may encounter PPT-045-01 32

Resources Safety Data Sheets (SDS) NFPA standards (National Fire Protection Association) NFPA Fire Protection Handbook PPT-045-01 33

Resources Technical manuals: Sax s Dangerous Properties of Industrial Materials Emergency guides: Emergency Response Guidebook Each cited source has valuable information toward monitor planning PPT-045-01 34

Resources NIOSH Pocket Guide to Chemical Hazards The following slides give an overview of the NIOSH categories to aid in your monitoring operations PPT-045-01 35

NIOSH Information Categories Name of material Formula CAS# RTECS# IDLH Conversion: PPM to Mg/M3 Synonyms/trade names Exposure Limits Measurement methods Chemical and physical properties PPE Respirator recommendations PPT-045-01 36

NIOSH Categories Incompatibilities and reactivities Exposure routes, symptoms, target organs First aid PPT-045-01 37

Propane as an Example Using Selected Categories: Formula: CH3CH2CH3 CAS#: Chemical abstract service number 74-98-6 RTECS#: Registry of toxic effects of chemical substances TX2275000 IDLH: 2100 PPM (10% LEL) Conversion: 1ppm = 1.80 mg/m3 OSHA PEL: TWA 1000 PPM (1800 Mg/M3). 1000 PPM/10,000=0.1 percent PPT-045-01 38

Propane as an Example Physical Description MW (Molecular Weight): 44.1 (44.1/29=1.52 vapor density) Fl.P (Flashpoint): NA (Not applicable due to being a gas) IP (Ionization Potential): 11.07 eV. A photoionization detector could be used to detect propane as long as the lamp used has an ionization energy greater than the IP of the material PPT-045-01 39

Propane RGasD: Relative gas density; heavier or lighter than air Propane has an RGasD of 1.52 making it 1.52 times heavier than air Monitor low in an area Propane is a hydrocarbon and will huddle in confined areas Always be thorough in your monitoring PPT-045-01 40

Propane UEL/LEL: 9.5 percent to 2.1 percent. If monitoring to stop when 10 percent by volume is found, 10 percent of the LEL of 2.1 percent is .21 percent Respirator recommendations for propane: (NIOSH) SA (supplied air) and/or SCBA (self- contained breathing apparatus) at or above 2100 PPM PPT-045-01 41

Detectors General types include: Passive badges and dosimeters Tubes/pumps Combustible gas indicator (CGI) Single gas Multiple gas Flame ionization detector (FID) Photoionization detector (PID) Radiological PPT-045-01 42

Dosimeters Passive Monitors Permeation of gases through a membrane onto a collection medium Film Badge Desorbed with carbon disulfide Analyzed by gas chromatograph *Air Monitoring for Toxic Exposures, Shirley A. Ness, Van Nostrand Reinhold, 1991, page 85 PPT-045-01 43

Tubes Test atmosphere is drawn into tube Tubes are gas/vapor specific Presence of gas/vapor changes reagent color in tube PPM and percentage gradients on tube indicate amount of gas/vapor in atmosphere PPT-045-01 44

Tubes and Pumps Specific number of pump strokes required for precise reading if using a manual pump Pump assemblies are calibrated to draw either 50cc or 100cc on each stroke when set PPT-045-01 45

Solid State Sensors Semiconductors can be used for: General survey monitors Specific gases and hydrocarbons Toxic gases Reads electrical resistance decreases across a Wheatstone bridge PPT-045-01 46

Combustible Gas Indicators Also called CGIs Catalytic combustion Voltage drop is read across a Wheatstone bridge PPT-045-01 47

Single Gas Sensor is gas-specific Electro-chemical principle Chemical specificity is due to electrodes and electrolytes used Ticker used by gas companies specific to their product Note sensing head PPT-045-01 48

Multiple Gas Visual and audible alarms Specific detector heads may be incorporated based on your hazards This one detects: Oxygen content Percent LEL Carbon monoxide Hydrogen sulfide PPT-045-01 49

Multiple Gas Read oxygen level first to verify correct level between 19.5 percent to 23.5 percent or reading for LEL will be incorrect for the challenge gas/vapor PPT-045-01 50