American Bridge/Fluor Joint Venture #891910 - Construction Project Overview

Learn about the American Bridge/Fluor Joint Venture #891910 construction project involving the Bay Bridge, including background information, history, current developments, and safety details. Discover key facts, including the project's scope, challenges faced, and ongoing work towards completing the new bridge.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

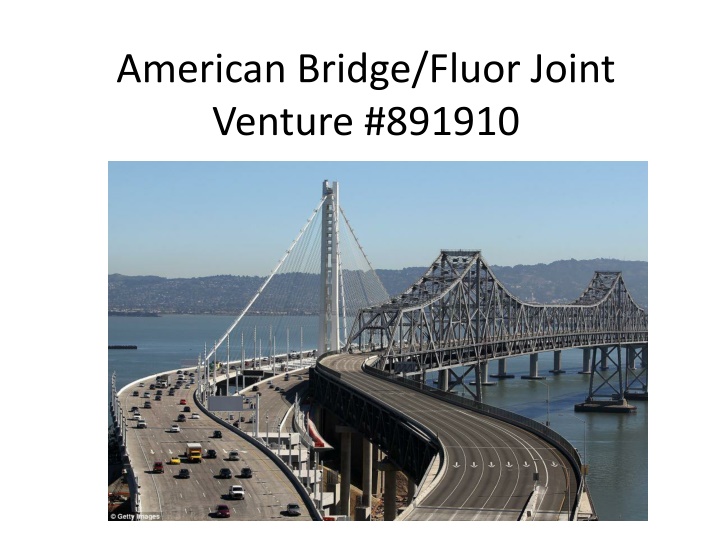

American Bridge/Fluor Joint Venture #891910

Background: On the afternoon of 2/21/13, the Oakland Area Office, Oakland, CA, learned through a media referral that there was a crane collapse under the eastern span of Bay Bridge. Although information was sparse, no injuries or fatalities were reported. An inspection was opened that day.

History: Following the 1989 Loma Prieta Earthquake (magnitude 6.9-7.1) with the epicenter 60 miles south of San Francisco, the eastern span of the then 70 year old Bay Bridge as well as connecting highways collapsed causing permanent structural damage. It was determined that a new seismically current bridge was needed.

A new bridge is being built: American Bridge/Fluor JV is awarded the contract by Caltrans. These international companies are known world wide for large, complicated construction projects and engineering and have been around for many years. Both companies have been inspected many times across the country and although not perfect, have good track records.

Bridge Facts: Average of 280,000 vehicles cross daily. It took years to complete the project and cost over $7 billion to complete. The bridge is self-anchored, the largest of it s kind in the world.

What was the activity when the accident occurred? An engineered, blind tandem lift using 2 Manitowoc ringer cranes. There were two crane operators, at least 3 employees on the floating barges, and 8 iron workers involved and were exposed to the hazards.

Where does Federal OSHA have jurisdiction? On the water (floating cranes). CA-OSHA/DOT had jurisdiction on the bridge and truss.

What other agencies might have some jurisdiction here? Other agencies on site: EPA and Coast Guard because barge was sinking and blocking waterway. Since there were not injuries or fatalities, their response took precedent.

What standards apply or should be considered? *1926.1425 (Demolition). ASME B30.5-2004, Section 5-3.2.1.5 (Mobile and Locomotive Cranes) ANSI A10.42-2000, (Safety Requirements for Rigging Qualifications and Responsibilities) Manitowoc Ringer Crane Safe Operating Practices (Crane Manual)

Who is the employer of the iron workers? The site consisted of at least 187 workers, both JV employees and iron workers from various union halls. The union halls supply the iron workers and give the pay checks but that alone does not make them an employer. An employer can be anyone directing work or controlling a worksite or making other workplace decisions. Employers affecting employees other than their own can also be cited.

What caused the accident? The center of gravity (COG) was miscalculated; a section of cord was miss measured by 1.9 ft. thereby throwing off the COG calculation. This caused the cradle/lifting frame to rotate an estimated 15 degrees (according to Fluor engineers). The cradle was only designed to rotate 10 degrees. The section of truss, weighing 129 tons, slid off the cradle. The cradle fell, impaling the landing barge below and causing it to take water.

Cont: The swinging cradle hit the boom block of ringer 2 and may have hit ringer 3. The boom of ringer 2swayed back and forth which caused the counter weights to fall off and the boom collapsed. The boom of ringer 3 got caught under the bridge and was damaged as well.

What could have been done differently? Are there feasible means of abatement?

This is what we came up with: The truss needed to be secured adequately to the lifting cradle. Lift with a wider cradle and remove smaller truss sections. Control the truss cut with cable bracing Install a sliding counter weight to the lifting cradle. Encourage ee s to speak up if something seems wrong .

What did the employer come up with? The employer built a new, wider, lifting cradle designed to withstand a 20 degree rotation and added slider weights to counter any rotation if the COG was off.

Other: 15 other engineer, blind tandem lifts had been performed without issue. Interviewed iron workers that torched the lower sections of truss thought something was wrong because the steel separated more than a foot after it was cut through; they didn t say anything because this had happened 2x previous with some movement but not like this.

Presented by Lisa Trecartin, Compliance Safety and Health Officer