Analysis of Plated Terminal Performance in Engineering Specification Test Report

This report details the testing procedures and results of plated terminals for connectors produced by Hyundai Motor Company. The testing includes visual inspections, plating thickness measurements, adhesion tests, and temperature resistance assessments. The performance of the plated terminals is evaluated against set requirements, ensuring reliability and quality for the specified project. Various parameters such as appearance, thickness, and adhesion are scrutinized to meet the specified standards. The report provides insights into the quality control measures and assessment criteria used in the evaluation of plated terminal performance.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

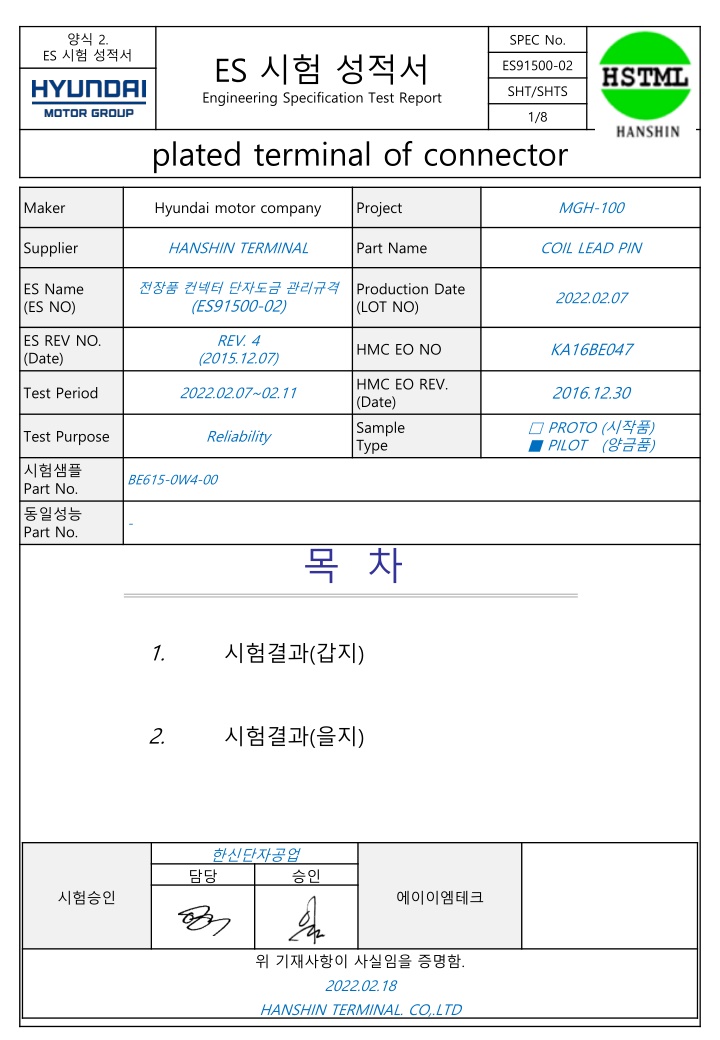

2. SPEC No. ES ES Engineering Specification Test Report ES91500-02 SHT/SHTS 1/8 plated terminal of connector Maker Hyundai motor company Project MGH-100 Supplier HANSHIN TERMINAL Part Name COIL LEAD PIN ES Name (ES NO) Production Date (LOT NO) (ES91500-02) 2022.02.07 ES REV NO. (Date) REV. 4 (2015.12.07) KA16BE047 HMC EO NO HMC EO REV. (Date) Sample Type 2016.12.30 Test Period 2022.02.07~02.11 PROTO ( ) PILOT ( ) Test Purpose Reliability Part No. Part No. BE615-0W4-00 - 1. ( ) 2. ( ) . 2022.02.18 HANSHIN TERMINAL. CO,.LTD

2. SPEC No. ES ES Engineering Specification Test Report ES91500-02 SHT/SHTS 2/8 1. ( ) Test No. Test Name Test Device Required Result Unit Judgment Remarks After visual inspection with magnification(over 10 ), the sample should satisfy the requirement performance. Visual inspection with magnification (over 10 ) Appearance (Min 1 metre) 5.2 - OK NG - Sn 1:0.4-1.5 0.85 Plating thickness X-RAY (CRF,SEM)1) 5.3 OK NG Average Ni 1:1.5-3 2.71 Pre-plated raw material and post- plated product are achieved peel up test with adhesion tape. Plating area is pasted and removed by adhesion tape for 3 times. After laying the available surface on test bending jig, 180 bending test is performed. 5.5 Peel up Tape - - OK NG 5.6 Bending Bending Jig - - OK NG After soaking the plated terminal in the high temperature chamber for 30 min., takeout and rapidly cool this sample to the outside at the room temperature. Plating area of cooling sample is inspected by magnification( 10)*Soa king temperature condition Sn/Sn-Pb plated terminal:150+/- 10 Heat 5.7 . - - OK NG resistance Test condition spray for 48 hrs + leave for 24 hrs 5.8 Salt Spray Tester - Hr OK NG

2. SPEC No. ES ES Engineering Specification Test Report ES91500-02 SHT/SHTS 3/8 2. ( ) 5.2 Appearance Maker Hyundai motor company Project HAN CHANG ENPLA (INTERPLEX) (ES91500-02) REV. 4 (2015.12.07) MGH-100 Supplier Part Name COIL LEAD PIN ES Name (ES NO) Production Date (LOT NO) 2022.02.07 ES REV NO. (Date) HMC EO NO - Test Period 2022.02.07~02.11 HMC EO REV. (Date) - Sample Type PROTO ( ) PILOT ( ) Test Purpose Reliability Part No. Part No. BE615-0W4-00 - After visual inspection with magnification(over 10 ), the sample should satisfy the requirement performance. Required Test Temp. (Measured) Temperature :25 5, Humidity:60% 20% RH Result Evaluation result Spec X1 X2 X3 X4 X5 X6 X7 X8 X9 X10 OK NG Appearance OK OK OK OK OK OK OK OK OK OK OK NG Tested by Controled by Approved by . 2022.02.18 HANSHIN TERMINAL. CO,.LTD

2. SPEC No. ES ES Engineering Specification Test Report ES91500-02 SHT/SHTS 4/8 2. ( ) 5.3 Plating thickness Maker Hyundai motor company Project HAN CHANG ENPLA (INTERPLEX) (ES91500-02) REV. 4 (2015.12.07) MGH-100 Supplier Part Name COIL LEAD PIN ES Name (ES NO) Production Date (LOT NO) 2022.02.07 ES REV NO. (Date) HMC EO NO - Test Period 2022.02.07~02.11 HMC EO REV. (Date) - Sample Type PROTO ( ) PILOT ( ) Test Purpose Reliability Part No. Part No. BE615-0W4-00 - Sn 1:0.4-1.5 Ni 1:1.5-3 Required Test Temp. (Measured) Temperature :25 5, Humidity:60% 20% RH Result Evaluation result Spec X1 X2 X3 X4 X5 X6 X7 X8 X9 X10 OK NG Sn 1 0.4~1.1 OK NG 0.882 0.821 0.818 0.856 0.868 Ni 1 1.5~3 OK NG 2.683 2.713 2.717 2.661 2.761 Tested by Controled by Approved by . 2022.02.18 HANSHIN TERMINAL. CO,.LTD

2. SPEC No. ES ES Engineering Specification Test Report ES91500-02 SHT/SHTS 5/8 2. ( ) 5.5 Peel up Maker Hyundai motor company Project HAN CHANG ENPLA (INTERPLEX) (ES91500-02) REV. 4 (2015.12.07) MGH-100 Supplier Part Name COIL LEAD PIN ES Name (ES NO) Production Date (LOT NO) 2022.02.07 ES REV NO. (Date) HMC EO NO - Test Period 2022.02.07~02.11 HMC EO REV. (Date) - Sample Type PROTO ( ) PILOT ( ) Test Purpose Reliability Part No. Part No. BE615-0W4-00 - Pre-plated raw material and post-plated product are achieved peel up test with adhesion tape. Plating area is pasted and removed by adhesion tape for 3 times. Required Test Temp. (Measured) Temperature :25 5, Humidity:60% 20% RH Result Evaluation result Spec X1 X2 X3 X4 X5 X6 X7 X8 X9 X10 OK NG OK OK OK OK OK OK OK OK OK OK OK NG Tested by Controled by Approved by . 2022.02.18 HANSHIN TERMINAL. CO,.LTD

2. SPEC No. ES ES Engineering Specification Test Report ES91500-02 SHT/SHTS 6/8 2. ( ) 5.6 Bending Maker Hyundai motor company Project HAN CHANG ENPLA (INTERPLEX) (ES91500-02) REV. 4 (2015.12.07) MGH-100 Supplier Part Name COIL LEAD PIN ES Name (ES NO) Production Date (LOT NO) 2022.02.07 ES REV NO. (Date) HMC EO NO - Test Period 2022.02.07~02.11 HMC EO REV. (Date) - Sample Type PROTO ( ) PILOT ( ) Test Purpose Reliability Part No. Part No. BE615-0W4-00 - Required After laying the available surface on test bending jig, 180 bending test is performed. Test Temp. (Measured) Temperature :25 5, Humidity:60% 20% RH Result Evaluation result Spec X1 X2 X3 X4 X5 X6 X7 X8 X9 X10 OK NG OK OK OK OK OK OK OK OK OK OK OK NG Tested by Controled by Approved by . 2022.02.18 HANSHIN TERMINAL. CO,.LTD

2. SPEC No. ES ES Engineering Specification Test Report ES91500-02 SHT/SHTS 7/8 2. ( ) 5.7 Heat resistance Maker Hyundai motor company Project HAN CHANG ENPLA (INTERPLEX) (ES91500-02) REV. 4 (2015.12.07) MGH-100 Supplier Part Name COIL LEAD PIN ES Name (ES NO) Production Date (LOT NO) 2022.02.07 ES REV NO. (Date) HMC EO NO - Test Period 2022.02.07~02.11 HMC EO REV. (Date) - Sample Type PROTO ( ) PILOT ( ) Test Purpose Reliability Part No. Part No. BE615-0W4-00 - After soaking the plated terminal in the high temperature chamber for 30 min., takeout and rapidly cool this sample to the outside at the room temperature. Plating area of cooling sample is inspected by magnification( 10)*Soaking temperature condition Sn/Sn-Pb plated terminal:150+/- 10 Required Test Temp. (Measured) Temperature :25 5, Humidity:60% 20% RH Result Evaluation result Spec X1 X2 X3 X4 X5 X6 X7 X8 X9 X10 OK NG OK OK OK OK OK OK OK OK OK OK OK NG Tested by Controled by Approved by . 2022.02.18 HANSHIN TERMINAL. CO,.LTD

2. SPEC No. ES ES Engineering Specification Test Report ES91500-02 SHT/SHTS 8/8 2. ( ) 5.8 Salt Spray Maker Hyundai motor company Project HAN CHANG ENPLA (INTERPLEX) (ES91500-02) REV. 4 (2015.12.07) MGH-100 Supplier Part Name COIL LEAD PIN ES Name (ES NO) Production Date (LOT NO) 2022.02.07 ES REV NO. (Date) HMC EO NO - Test Period 2022.02.07~02.11 HMC EO REV. (Date) - Sample Type PROTO ( ) PILOT ( ) Test Purpose Reliability Part No. Part No. BE615-0W4-00 - 1) After masking all area with breakage line except Au plating area on plated terminal, terminal is dried at normal temperature until masking surface is hard Sat water concentration and water temperature should be 5% and 35 ,reapectively. Test sample should be slided by 20 degree in order to flow the saltwater. *Test condition spray for 48 hrs + leave for 24 hrs Required 2) Test Temp. (Measured) Temperature :25 5, Humidity:60% 20% RH Result Evaluation result Spec X1 X2 X3 X4 X5 OK NG OK OK OK OK OK OK NG Tested by Controled by Approved by . 2022.02.18 HANSHIN TERMINAL. CO,.LTD