Applied FMEA for Manufacturing Plastic Components in Automotive Industry

Dive into how FMEA was utilized at Thomas Romania Plastic for risk identification in the manufacturing process of plastic components for the automotive sector, leading to enhanced quality control, customer satisfaction, and cost reduction.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

REKTRON AB APPLIED FMEA FOR MANUFACTURING PLASTIC COMPONENTS IN THE AUTOMOTIVE INDUSTRY

REKTRON AB Organization: Thomas Romania Plastic B-dul Muncii, No. 16, Cluj-Napoca, Cluj, 400641, Romania Website and social media: Website: www.thomas-tontec.com/ Social media (Facebook): https://www.facebook.com/pages/Thomas-Romania-Plastic/448847321895245 Contact details: Ionut Suciu Tel. +40 264 411 970 E-mail: ionut.suciu@thomas-tontec.com

REKTRON AB Type of organization: SME Market sectors: Mechanical engineering Services provided: Engineering Manufacturing

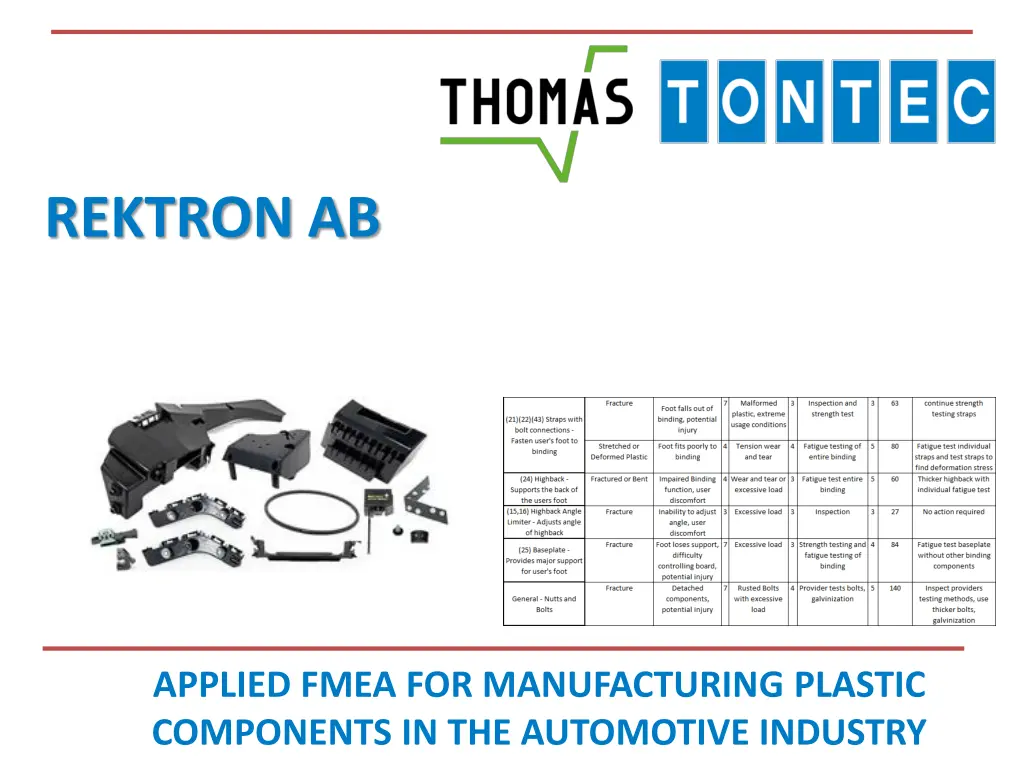

REKTRON AB Description of the solution The FMEA method was applied within Thomas Romania Plastic, a mold injection manufacturing company, which produces plastic components for the automotive industry. In this particular case, the method was used for identifying risks related to the functioning of the manufacturing process, before starting the serial production, in the product validation stage. This risk analysis was adjusted to the main stages of the process, in accordance with its flow chart, among which, worth mentioning are: material reception, components incoming check, mold injection (initial setup, startup confirmation, serial production), packaging, storage, delivery.

REKTRON AB Technical solutions and innovations In Thomas-Tontec process FMEA is used as a preventive tool and includes both product and manufacturing process risk analysis. The results are used to develop the work instructions for production operators and quality inspectors. Checking methods include: appearance check, dimensional check (with measuring instruments CMM caliper, micrometer, control gauges), verifying incoming documentation (quality certification, checklists) The use of the FMEA method helps in identifying non-conforming parts, before reaching the customer. This way, the customer satisfaction is increased, the complaints are decreased, and by keeping the processes under control, from this perspective, the overall quality of the manufactured product is also increased.

REKTRON AB Results/Impact The impact of the FMEA method is that it reduces non-conforming workpieces, it significantly reduces costs of poor quality and it is also useful for making process forecasts. To improve the impact of process FMEA is always recommended to use a multidisciplinary team with competence in different fields: engineering, production, quality, logistics, human resources. The FMEA is a very useful tool if used properly, before the start of serial production, during the product and process development phase. A lot of inconveniences and costs could be eliminated/ avoided.