Brushed DC Motors and Their Common Applications

Brushed DC motors are essential components in consumer goods, small appliances, and automotive applications due to their simple construction and high torque capabilities. This article explores the main parts of a brushed motor, how they work, the bipolar nature of DC motors, common usages, and a comparison between brushed and brushless motors in terms of advantages and disadvantages.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

BRUSHED DC MOTORS GEORGIA TECH ECE LABS SLIDES BY MATTHEW KOHN

MAIN PARTS TO A BRUSHED MOTOR Field coil (stator) Non-moving part of the magnetic circuit on which a magnetic field is produced through winding it around. Armature (rotor) Part that rotates around its axis and is separated from the field coil by an air gap. Conductors are evenly distributed around its outer surface Commutator and Brushes Commutator is a device connected to the armature of a motor and it ensures that current flows as direct current

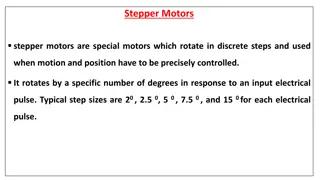

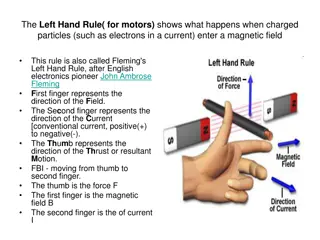

HOW DO THESE PARTS WORK? When the coil is energized the magnetic field in the air gap in the direction of the armature "enters" the armature from the north pole and "exits" through the south pole side of the field coil Conductors located under the other pole are subject to the same intensity in the opposite direction and these opposing forces cause torque which rotates the motor armature.

DC MOTORS ARE BIPOLAR? When it is said that DC motors are bipolar it means that they are reversible (can turn in either direction clockwise or counter- clockwise) and can be easily controlled by inverting the polarity of the applied voltage. If a motor is already in motion, the applied voltage can be inverted and the motor will decelerate quickly, eventually stopping. A product of being bipolar is "Flyback" current which occurs when the induced voltage across the inductor of opposite polarity favors the opposite polarity forward biases the diode, and it conducts current, limiting the voltage across the inductor and thus preventing the arc from forming at the switch Decreases slowly to zero as the magnetic energy in the inductor is dissipated as heat in the series resistance of the windings

COMMON USAGES OF BRUSHED DC MOTORS Brushed DC motors are common in many consumer goods, small appliances, and automotive applications such as power seats and windshield wipers. In industrial applications brushed motors make sense to use when high torque is required primarily during acceleration ad deceleration.

BRUSHED OR BRUSHLESS Advantages of Brushed Low overall construction costs Can often be rebuilt to extend life Simple and inexpensive controller Controller not needed for fixed speed Ideal for extreme operating environments Disadvantages of Brushed Less reliable in control at lowest speeds Physically larger than other motors producing equivalent torque Considered high-maintenance, which isn't true of brushless Vulnerable to dust which decreases performance