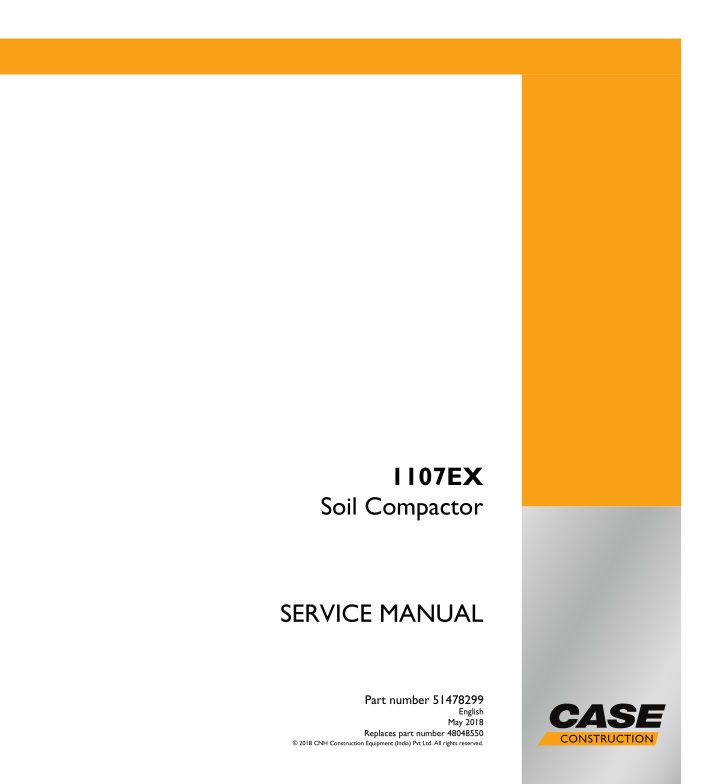

CASE 1107EX Soil Compactor Service Repair Manual Instant Download

CASE 1107EX Soil Compactor Service Repair Manual Instant Download

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

1107EX Soil Compactor SERVICE MANUAL Part number 51478299 English May 2018 Replaces part number 48048550 2018 CNH Construction Equipment (India) Pvt Ltd. All rights reserved.

Link Product / Engine Product Market Product Latin America Latin America Asia Pacific Latin America Middle East Africa Middle East Africa Asia Pacific Asia Pacific Middle East Africa Engine 8045.45.747 8045.45.751 8045.45.747 8045.45.747 8045.45.747 8045.45.751 8045.45.747 8045.45.751 8045.45.747 1107EX ROPS CANOPY 1107EX ROPS CAB 1107EX NON ROPS CANOPY 1107EX NON ROPS CANOPY 1107EX NON ROPS CANOPY 1107EX ROPS CAB 1107EX ROPS CANOPY 1107EX ROPS CAB 1107EX ROPS CANOPY 51478299 08/05/2018

Contents INTRODUCTION Engine....................................................................................... 10 [10.001] Engine and crankcase ............................................................. 10.1 [10.202] Air cleaners and lines .............................................................. 10.2 [10.254] Intake and exhaust manifolds and muffler ......................................... 10.3 [10.400] Engine cooling system ............................................................. 10.4 [10.414] Fan and drive ...................................................................... 10.5 [10.310] Aftercooler.......................................................................... 10.6 Rear axle system........................................................................ 27 [27.100] Powered rear axle.................................................................. 27.1 [27.106] Rear bevel gear set and differential................................................ 27.2 [27.120] Planetary and final drives .......................................................... 27.3 [27.124] Final drive hub, steering knuckles, and shafts ..................................... 27.4 [27.AAA] Rear axle system generic sub-group.............................................. 27.5 Hydrostatic drive......................................................................... 29 [29.218] Pump and motor components...................................................... 29.1 Brakes and controls .................................................................... 33 [33.120] Mechanical service brakes......................................................... 33.1 [33.110] Parking brake or parking lock ...................................................... 33.2 Hydraulic systems....................................................................... 35 [35.000] Hydraulic systems.................................................................. 35.1 [35.300] Reservoir, cooler, and filters........................................................ 35.2 Frames and ballasting................................................................. 39 [39.100] Frame .............................................................................. 39.1 [39.500] Vibratory roller...................................................................... 39.2 [39.AAA] Frames and ballasting generic sub-group......................................... 39.3 51478299 08/05/2018

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

Steering..................................................................................... 41 [41.101] Steering control .................................................................... 41.1 [41.200] Hydraulic control components...................................................... 41.2 [41.206] Pump............................................................................... 41.3 [41.216] Cylinders ........................................................................... 41.4 Wheels...................................................................................... 44 [44.520] Rear wheels........................................................................ 44.1 Cab climate control..................................................................... 50 [50.100] Heating............................................................................. 50.1 [50.200] Air conditioning..................................................................... 50.2 Electrical systems....................................................................... 55 [55.000] Electrical system ................................................................... 55.1 [55.100] Harnesses and connectors......................................................... 55.2 [55.201] Engine starting system............................................................. 55.3 [55.301] Alternator........................................................................... 55.4 [55.302] Battery.............................................................................. 55.5 Platform, cab, bodywork, and decals............................................. 90 [90.150] Cab................................................................................. 90.1 [90.110] Operator platform less cab ......................................................... 90.2 [90.102] Engine shields, hood latches, and trims ........................................... 90.3 [90.AAA] Platform, cab, bodywork, and decals generic sub-group.......................... 90.4 51478299 08/05/2018

INTRODUCTION 51478299 08/05/2018 1

INTRODUCTION Safety rules Personal safety This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible death or injury. Throughout this manual you will find the signal words DANGER, WARNING, and CAUTION followed by special in- structions. These precautions are intended for the personal safety of you and those working with you. Read and understand all the safety messages in this manual before you operate or service the machine. DANGER indicates a hazardous situation that, if not avoided, will result in death or serious injury. WARNING indicates a hazardous situation that, if not avoided, could result in death or serious injury. CAUTION indicates a hazardous situation that, if not avoided, could result in minor or moderate injury. FAILURE TO FOLLOW DANGER, WARNING, AND CAUTION MESSAGES COULD RESULT IN DEATH OR SERIOUS INJURY. Machine safety NOTICE: Notice indicates a situation that, if not avoided, could result in machine or property damage. Throughout this manual you will find the signal word Notice followed by special instructions to prevent machine or property damage. The word Notice is used to address practices not related to personal safety. Information NOTE: Note indicates additional information that clarifies steps, procedures, or other information in this manual. Throughout this manual you will find the word Note followed by additional information about a step, procedure, or other information in the manual. The word Note is not intended to address personal safety or property damage. 51478299 08/05/2018 3

INTRODUCTION Safety rules DANGER Improper operation or service of this machine can result in an accident. Do not operate this machine or perform any lubrication, maintenance, or repair on it until you have read and understood the operation, lubrication, maintenance, and repair information. Failure to comply will result in death or serious injury. D0010A WARNING Maintenance hazard! Always perform all service procedures punctually at the intervals stated in this manual. This ensures optimum performance levels and maximum safety during machine operation. Failure to comply could result in death or serious injury. W0132A NOTICE: Extreme working and environmental conditions require shortened service intervals. Use Case fluids, lubricants, and filters for the best protection and performance of your machine. All fluids, lubricants, and filters must be disposed of in compliance with environmental standards and regulations. Contact your Dealer with any questions regarding the service and maintenance of this machine. Use this manual with the operator's manual to understand and perform the complete service procedures. Read the safety decals and information decals on the machine. Read the Operator s Manual and safety manual. Understand the operation of the machine before you start any service. Before you service the machine, put a Do Not Operate tag on the steering wheel or over the key switch. Ensure the tag is at a location where everyone who might operate or service the machine may see clearly. Plastic and resin parts Avoid using gasoline, paint thinner, etc. when cleaning plastic parts, console, instrument cluster, etc. Use only water, mild soap, and a soft cloth when you clean these parts. Using gasoline, thinners, etc. can cause discoloration, cracking, or deformation of the part being cleaned. 51478299 08/05/2018 4

INTRODUCTION Safety rules - Ecology and the environment Soil, air, and water are vital factors of agriculture and life in general. When legislation does not yet rule the treatment of some of the substances required by advanced technology, sound judgment should govern the use and disposal of products of a chemical and petrochemical nature. NOTE: The following are recommendations that may be of assistance: Become acquainted with and ensure that you understand the relative legislation applicable to your country. Where no legislation exists, obtain information from suppliers of oils, filters, batteries, fuels, antifreeze, cleaning agents, etc., with regard to their effect on man and nature and how to safely store, use, and dispose of these substances. Helpful hints Avoid filling tanks using cans or inappropriate pressurized fuel delivery systems that may cause considerable spillage. In general, avoid skin contact with all fuels, oils, acids, solvents, etc. Most of them contain substances that may be harmful to your health. Modern oils contain additives. Do not burn contaminated fuels and or waste oils in ordinary heating systems. Avoid spillage when draining off used engine coolant mixtures, engine, gearbox and hydraulic oils, brake fluids, etc. Do not mix drained brake fluids or fuels with lubricants. Store them safely until they can be disposed of in a proper way to comply with local legislation and available resources. Modern coolant mixtures, i.e. antifreeze and other additives, should be replaced every two years. They should not be allowed to get into the soil, but should be collected and disposed of properly. Repair any leaks or defects in the engine cooling or hydraulic system immediately. Do not increase the pressure in a pressurized circuit as this may lead to a component failure. Protect hoses during welding as penetrating weld splatter may burn a hole or weaken them, allowing the loss of oils, coolant, etc. 51478299 08/05/2018 5

SERVICE MANUAL Engine 1107EX 51478299 08/05/2018 10

Engine - Engine and crankcase Engine - Torque 1 PTIL18COM0016GB Bolt 1 2 3 Torque value 135 N m 125 N m 120 N m 51478299 08/05/2018 10.1 [10.001] / 3

Engine - Engine and crankcase Engine and crankcase - Service instruction The S8000 series of engine is a vertical, water cooled, direct Injection, with rotary pump compression ignition, 4 cylinder engine. The standard direction of rotation is anti-clockwise when looking from the flywheel end. Cylinders are numbered ascending from the radiator end, with first cylinder being nearest to the cooling fan. The engine has an integral block and crank case for rigidity and a single piece cylinder head unit covering all cylinders, with replaceable valve seat inserts. Each cylinder has two valves, one inlet and one exhaust. The valve nearest to the cooling fan is the exhaust valve fol- lowed inlet valve. This sequence of valves continues uniformly for all cylinders 51478299 08/05/2018 10.1 [10.001] / 4

Engine - Engine and crankcase Engine and crankcase - Remove 1. Remove the hood, refer to Engine shields, hood latches, and trims - Remove - Hood Removal (90.102). 2. Remove the receiver drier from the engine. Refer Air conditioning - Remove - Receiver drier (50.200). 3. Remove the condenser from the engine. Refer Air- conditioning condenser - Remove (50.200). 4. Remove the cooling pack. Refer Engine cooling sys- tem - Remove - Cooling pack (10.400). 5. Loosenandremovethethermostatmountinghosecon- nections and cap the openings. 6. Disconnect the alternator connections. Refer Alterna- tor - Remove (55.301). 7. Disconnect the engine oil pressure sensor connection. 8. Loosen the clamp and remove the silencer assembly. Refer Exhaust pipes - Remove (10.254) 9. All the hydraulic and oil connector openings to be cov- ered properly to avoid entry of dust. 10. Disconnect the clog indicator connection and remove the air filter assembly with housing and pipes to intake manifold. Refer Air pre-cleaner - Exploded view (10.202) 11. Disconnect all the starter connections. Refer Engine starter - Remove (55.201) . 12. Remove the travel and vibration pumps. Refer Pump - Remove - Travel pump (29.218). 13. Lift the pump and set it aside. 14. Remove the hydraulic filter assembly. 15. Loosen the bolts (2) and remove the adapter (1) from the engine bell housing. 1 PTIL16TLB0324AB 51478299 08/05/2018 10.1 [10.001] / 5

Engine - Engine and crankcase 16. Loosen the bolts (2) and remove the coupling (1) from the flywheel. 2 PTIL16TLB0325AB 17. Disconnectthehydrauliclines(1)atthesteeringpump end and cap the openings. Set the hose aside. 3 PTIL14COM1364AB 18. Disconnect the fuel hoses from the fuel tank to mud filter and cap them. 19. Disconnect the fuel hose from filter to engine and to mud filter and cap them. 20. Disconnect the emergency stop switch. 21. Disconnect the throttle cable at the pump end and clear the cable from the engine. 22. Connect a suitable lifting device to the engine. 23. Loosen and remove the bolts (1) with washer (2). 24. Loosen and remove the bolts (3) with washer (4). NOTE: The bolt (5) is different from other bolts on the mounting bracket and has an additional alternator bracket spacer (6). Put an identification tag on the bolt and make sure to install the bolt in same location while mounting the engine. 4 PTIL18COM0017AA 51478299 08/05/2018 10.1 [10.001] / 6

Engine - Engine and crankcase 25. Lift the engine slowly. 26. Clear any cables or wires that may be in the way. 27. Lift the engine clear of the machine and mount on a trolley or stand. 51478299 08/05/2018 10.1 [10.001] / 7

Engine - Engine and crankcase Engine and crankcase - Install 1 PTIL18COM0016GA 1. Place the engine on the machine by using suitable lift- ing device. 2. Tighten the four mounting bolts (1) with washer (2) to a torque of 125 N m. 3. Tighten the mounting bolts (3) with washer (4) and (5) to a torque of 120 N m. 51478299 08/05/2018 10.1 [10.001] / 8

Engine - Engine and crankcase 4. Torque the mounting bolt (6) to 125 N m. NOTE: The mounting bolt (6) is different from other mount- ing bolts on the same bracket and has additional alternator bracket spacer (7). 2 PTIL18COM0017AA NOTE: Apply anabond 121 E on threads of bolts (2), (4), and (6) from approximately middle of thread length up to end of thread length. Allow minimum 6 h of curing time before applying the dynamic load on bolts. Before applying anabond, clean the bolt and corresponding thread hole so that it should be free from oil and dirt. 5. Install the throttle cable at the pump end and install the cable to the engine. 6. Install the emergency stop switch. 7. Install the fuel hose from filter to engine and to mud filter. 8. Install the fuel hoses from the fuel tank to mud filter. 9. clean the hose and connect the hydraulic lines (1) at the steering pump and cap opening. 3 PTIL14COM1364AB 10. Install the coupling (1) on to the flywheel. Install the washer and tighten the bolts (2) to a torque of 5 kgm. 4 PTIL16TLB0325AB 51478299 08/05/2018 10.1 [10.001] / 9

Engine - Engine and crankcase 11. Install the adapter (1) on to the engine bell housing and tighten the bolts (2) to a torque of 6.3 kgm. 5 PTIL16TLB0324AB 12. Install the hydraulic filter assembly. 13. Install the travel and vibration pumps. Refer Pump - Install - Travel pump (41.206). 14. Install all the starter connections. starter - Install (55.201). Refer Engine 15. Install the air filter assembly with housing and pipes to intake manifold and connect the clog indicator connection. Refer Air pre-cleaner - Exploded view (10.202). 16. Remove the cover from hydraulic and oil connector openings assembly. 17. Install the silencer assembly and tighten the clamp. Refer Exhaust pipes - Install (10.254). 18. Install the engine oil pressure sensor connection. 19. Install the alternator connections. Refer Alternator - Install (55.301). 20. Install the thermostat mounting hose connections and cap openings. 21. Install the cooling pack. Refer Engine cooling sys- tem - Install - Cooling pack (10.400). 22. Install the condenser in the engine. Refer Air-condi- tioning condenser - Install (50.200). 23. Install the receiver drier in the engine. Refer Air con- ditioning - Install - Receiver drier (50.200). 24. Install the hood. latches, and trims - Install (90.102) Refer Engine shields, hood 51478299 08/05/2018 10.1 [10.001] / 10

Engine - Engine and crankcase Engine and crankcase - Disassemble - Top Engine 1. Disconnect the battery and store it in a dry place. 2. Remove the radiator fan. 3. Disconnect wiring from the alternator. 4. Remove fan belt. Discard if it is damaged. 5. Remove the alternator (1) from the engine. 1 PTIL16TLB0326AB 6. Drain out water from the radiator. NOTE: If coolant is used, collect it in a container and use again. 7. Drain the lubricating oil from the sump and discard the O-ring from the drain plug. 8. Disconnecttheradiatorfromtheengineanddiscardthe old hoses. 9. Disconnect the air cleaner and hose assembly from the bracket and inlet manifold. Discard the hose if it is cracked or damaged. 10. Disconnect the exhaust pipe from the exhaust flange. 11. Follow the procedure on turbocharger, 1. Disconnect the rubber hose (1) connecting the air cleaner to the turbocharger. 2. Disconnect the air delivery pipe with the heat shield from the turbocharger air outlet and air inlet mani- fold. 3. Disconnect the exhaust pipe (1) from the tur- bocharger expansion bellow flange and discard the joint. 4. Disconnect and remove the exhaust diffuser from the bracket. 2 PTIL16TLB0333AB 51478299 08/05/2018 10.1 [10.001] / 11

Engine - Engine and crankcase 5. Disconnect the lubrication oil inlet (1) and drain pipe from the turbocharger. 3 PTIL14COM1301AB 4 PTIL14COM1357AA 6. Disconnect the turbocharger from the exhaust man- ifold and discard the joint. 51478299 08/05/2018 10.1 [10.001] / 12

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

Engine - Engine and crankcase Engine and crankcase - Adjust 1. Move the machine to a level and firm ground. 2. Make sure that the FNR lever is in neutral position. 3. Engage the parking brake. 4. Stop the engine and remove the key. 5. Wait until the engine reaches ambient temperature be- fore performing any maintenance activity. 6. Inspect the V-belt over the whole length for damage or cracks. Replace damaged or cracked V-belt. NOTE: Wherever two belts are applicable, change the belts in pair only. For machine with cab 7. Check by pressing midway between the pulleys (A) (span between alternator and fan pulley) and measure the fan belt deflection inwards. The fan belt deflection should be 10.0 15.0 mm (0.4 0.6 in). 8. To adjust the belt, first loosen the bolt (3). To tighten the belt (1),screw out (i.e. rotate anti-clockwise) the nuts (2). To loosen the belt (1) screw in (i.e. rotate clockwise) the nuts (2). NOTE: Screw in or screw out both nuts (2) equally during belt adjustment. 9. After adjusting the belt, 90 100 N m tighten the bolt (3) to 1 PTIL17COM1098AA For machine with canopy 10. Check by pressing midway between the pulleys (A) (spanbetweenalternatorandfanpulley)andmeasure the fan belt deflection inwards. The fan belt deflection should be 10.0 15.0 mm (0.4 0.6 in). 11. To adjust the belt (1), loosen the alternator mounting bolts (3). 12. Slide the alternator (2) away from the engine to tighten the belt. Slide the alternator toward the engine to loosen the belt. 2 PTIL12TLB0178AB 13. After adjusting the belt, tighten the bolt (3) to 90 100 N m 51478299 08/05/2018 10.1 [10.001] / 13

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com