CASE IH RB465 Round Baler Service Repair Manual Instant Download (PIN 757301001 and above)

CASE IH RB465 Round Baler Service Repair Manual Instant Download (PIN 757301001 and above)

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

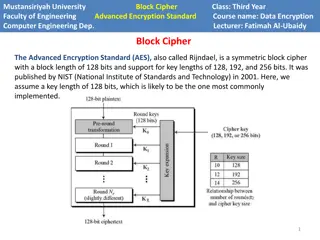

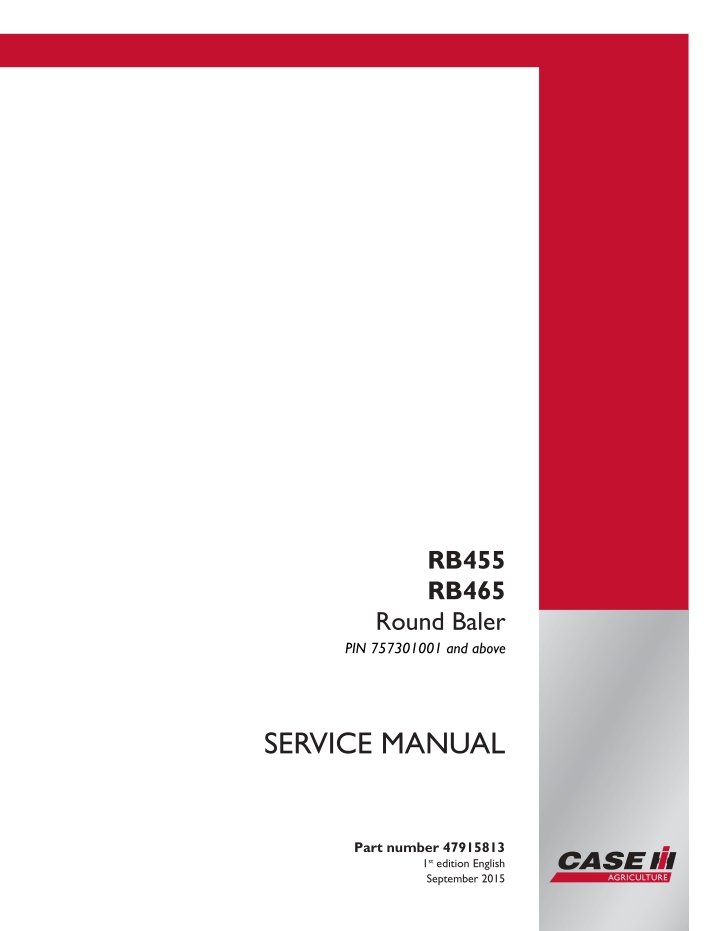

RB455 RB465 Round Baler PIN 757301001 and above SERVICE MANUAL Printed in U.S.A. Part number 47915813 1st edition English September 2015 2015 CNH Industrial America LLC. All Rights Reserved. Case IH is a trademark registered in the United States and many other countries, owned by or licensed to CNH Industrial N.V., its subsidiaries or affiliates.

Contents INTRODUCTION Rear axle system........................................................................ 27 [27.550] Non-powered rear axle............................................................. 27.1 Power Take-Off (PTO)................................................................. 31 [31.201] Power Take-Off (PTO) drive shaft.................................................. 31.1 [31.220] Gearbox............................................................................ 31.2 [31.225] Clutches............................................................................ 31.3 Brakes and controls .................................................................... 33 [33.202] Hydraulic service brakes ........................................................... 33.1 [33.300] Pneumatic service brakes.......................................................... 33.2 Hydraulic systems....................................................................... 35 [35.000] Hydraulic systems.................................................................. 35.1 [35.540] Bale density circuit ................................................................. 35.2 [35.550] Tailgate circuit...................................................................... 35.3 [35.560] Pickup lift circuit.................................................................... 35.4 [35.565] Cutter control circuit................................................................ 35.5 [35.569] Drop floor circuit.................................................................... 35.6 [35.570] Bale eject circuit.................................................................... 35.7 Electrical systems....................................................................... 55 [55.000] Electrical system ................................................................... 55.1 [55.100] Harnesses and connectors......................................................... 55.2 [55.422] Ejection/Unloading control system ................................................. 55.3 [55.433] Twine and net cutting and tying or wrapping....................................... 55.4 [55.629] Pressing/Bale formation electrical control.......................................... 55.5 [55.630] Bale density system................................................................ 55.6 [55.640] Electronic modules................................................................. 55.7 47915813 18/08/2015

[55.DTC] FAULT CODES.................................................................... 55.8 Product feeding.......................................................................... 60 [60.222] Wide pickup with over shot feeder ................................................. 60.1 [60.223] Wide pickup with rotor cutter or feeder............................................. 60.2 [60.260] Rotor ............................................................................... 60.3 Pressing - Bale formation............................................................. 62 [62.140] Bale formation...................................................................... 62.1 [62.141] Belt de-clutch....................................................................... 62.2 [62.150] Starter roll .......................................................................... 62.3 [62.153] Stationary roll ...................................................................... 62.4 [62.155] Stripper roll......................................................................... 62.5 [62.160] Floor roll............................................................................ 62.6 [62.170] Sledge.............................................................................. 62.7 Tying/Wrapping/Twisting.............................................................. 68 [68.170] Net wrapper ........................................................................ 68.1 [68.180] Twine wrapper...................................................................... 68.2 Ejection..................................................................................... 70 [70.280] Bale ejector components........................................................... 70.1 Lubrication system...................................................................... 71 [71.460] Grease lubrication system ......................................................... 71.1 [71.480] Oiler system........................................................................ 71.2 Platform, cab, bodywork, and decals............................................. 90 [90.105] Machine shields and guards ....................................................... 90.1 [90.108] Decals and plates .................................................................. 90.2 47915813 18/08/2015

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

INTRODUCTION 47915813 18/08/2015 1

INTRODUCTION Foreword - Important notice regarding equipment servicing All repair and maintenance work listed in this manual must be carried out only by qualified dealership personnel, strictly complying with the instructions given, and using, whenever possible, the special tools. Anyone who performs repair and maintenance operations without complying with the procedures provided herein shall be responsible for any subsequent damages. The manufacturer and all the organizations of its distribution chain, including - without limitation - national, regional, or local dealers, reject any responsibility for damages caused by parts and/or components not approved by the manu- facturer, including those used for the servicing or repair of the product manufactured or marketed by the manufacturer. In any case, no warranty is given or attributed on the product manufactured or marketed by the manufacturer in case of damages caused by parts and/or components not approved by the manufacturer. The manufacturer reserves the right to make improvements in design and changes in specifications at any time without notice and without incurring any obligation to install them on units previously sold. Specifications, descriptions, and illustrative material herein are as accurate as known at time of publication but are subject to change without notice. In case of questions, refer to your CASE IH Sales and Service Networks. 47915813 18/08/2015 3

INTRODUCTION Safety rules Personal safety This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible death or injury. Throughout this manual you will find the signal words DANGER, WARNING, and CAUTION followed by special in- structions. These precautions are intended for the personal safety of you and those working with you. Read and understand all the safety messages in this manual before you operate or service the machine. DANGER indicates a hazardous situation that, if not avoided, will result in death or serious injury. WARNING indicates a hazardous situation that, if not avoided, could result in death or serious injury. CAUTION indicates a hazardous situation that, if not avoided, could result in minor or moderate injury. FAILURE TO FOLLOW DANGER, WARNING, AND CAUTION MESSAGES COULD RESULT IN DEATH OR SERIOUS INJURY. Machine safety NOTICE: Notice indicates a situation that, if not avoided, could result in machine or property damage. Throughout this manual you will find the signal word Notice followed by special instructions to prevent machine or property damage. The word Notice is used to address practices not related to personal safety. Information NOTE: Note indicates additional information that clarifies steps, procedures, or other information in this manual. Throughout this manual you will find the word Note followed by additional information about a step, procedure, or other information in the manual. The word Note is not intended to address personal safety or property damage. 47915813 18/08/2015 4

INTRODUCTION Safety rules Personal safety General safety rules NOTICE:Usecautionwhenoperatingthemachineonany sloping terrain. A raised tailgate or full bale in the bale chamber will change the center of gravity of the machine. The machine can tip or roll over when near ditches, em- bankments, or uneven surfaces. 1 NHVM12RB00300AA NOTICE: High voltage power lines may require additional and significant clearance for safety due to the possibility of arcing between the power line and the baler. Pay attention to overhead power lines and hanging obsta- cles. When determining the needed clearance below obstacles and power lines, understand that when the baler is in the configuration described and shown, the distance (A), from a level ground surface to the highest point of the spare net roll storage box is 4.8 m (16 ft). Equipped with large diameter wheels and tires Equipped with a spare net roll storage box The tailgate fully raised. The bale chamber is empty. 2 NHIL13RB00053FA As the tractor driver and baler operator, never permit ride-along passengers on the tractor, in the tractor cab, or anyone to ride on the baler while being towed or operated. Never operate the machine under the influence of alcohol, drugs, or while otherwise impaired. Hydraulic oil or diesel fuel leaking under pressure can penetrate the skin, causing serious injury and infection. DO NOT use your hand to check for leaks. Use a piece of cardboard or paper. Stop engine, remove the key and relieve the pressure before connecting or disconnecting fluid lines. Make sure all components are in good condition and tighten all connections before starting the engine or pressur- izing the system. If hydraulic fluid or diesel fuel penetrates the skin, seek medical attention immediately. Continuous long term contact with hydraulic fluid may cause skin cancer. Avoid long term contact with hydraulic fluid. Wash the skin promptly with soap and water after contact with hydraulic fluid. Keep clear of moving parts. Loose clothing, jewelry, watches, long hair, and other loose or hanging items can entangle in moving parts. Wear protective equipment when appropriate. DO NOT attempt to remove material from any part of the machine while the machine is operating, any of the baler components are in motion, or while the tractor engine is running. 47915813 18/08/2015 5

INTRODUCTION Before you operate the machine, install and securely close all of the machine guards and shields. Make sure that all the guards and that all the shields are in good condition. Never operate the machine with shields open or removed. Always close the access doors and/or access panels before operating the machine. Make sure that no bystanders or pets are within the machine operating area. The machine and/or moving component on the machine can strike or crush bystanders or pets. DO NOT allow anyone to enter the work area. A raised tailgate can fall unexpectedly and crush persons underneath. Never allow anyone to enter the area under- neath a raised tailgate during operation. General maintenance safety Keep the area used for servicing the machine clean and dry. Clean up spilled fluids. Only service the machine on a firm level surface. WARNING Fall hazard! Remove wrapped crop debris from the forming rollers by clearing the bale chamber, removing belt ten- sion, and engaging the tailgate lockout valves. Remove wrapped debris from inside the bale chamber or tailgate. Do not climb on the exterior of the baler to remove wrapped debris. Failure to comply could result in death or serious injury. W0039A If you cannot reach certain areas of the machine from ground level, use a suitable ladder or other appropriate means to gain access. Do not climb on the machine for any reason. To access and clean the bale forming rolls, see Basic instructions Removing crop debris () or Basic instructions Cleaning the machine (). Install and close all the removed or opened guards and all the removed or open shields after servicing the machine. Close all the access doors and install all panels after servicing the machine. Do not attempt to clean, lubricate, clear obstructions, or adjust the machine while the machine operating, any of the baler components are in motion, or while the tractor engine is running. Always make sure that working area is clear of tools, parts, other persons, and pets before you start operating the machine. Always engage the tailgate lockout valve when the tailgate is open for service. A disengaged tailgate hydraulic lockout valve or unsupported hydraulic cylinders can lose pressure and drop the tailgate causing a crushing hazard. Do not leave the machine in a raised tailgate position while parked or during service, unless the tailgate is securely supported and/or the tailgate lockout valve engaged. Jack or lift the machine only at jack or lift points indicated in this operator s manual. Incorrect towing procedures can cause accidents. When towing a disabled machine follow the towing procedures in this operator s manual. Use only rigid tow bars. Stop the engine, remove the key, and relieve pressure before disconnecting or connecting fluid lines. Stop the engine and remove the key before disconnecting or connecting electrical connections. Replace damaged or worn tubes, hoses, electrical wiring, etc. Some electrical components and/or some hydraulic lines may become hot during operation. Take care when servic- ing such components. Allow the component surfaces to cool before handling the components or disconnecting hot components. Wear protective equipment when appropriate. When welding on or in close proximity to this machine, follow the instructions in this operator s manual. See Wheels and tires safety rules that follow in this chapter. Always disconnect the battery before welding on the machine. Always wash your hands after handling battery com- ponents. 47915813 18/08/2015 6

SERVICE MANUAL Rear axle system RB455 RB465 47915813 18/08/2015 27

Rear axle system - Non-powered rear axle Rear axle - General specification - Tire configurations The baler can come equipped from the factory with four different tire size configurations: (1) 31 x 13.5-15, 8 ply (2) 380/55-17, 10 ply (3) 480/45-17, 10 ply (4) 500/55-20, 10 ply 1 NHIL13RB00611AA NOTICE: Torque all wheel lugs in the order that is described below. Regularly check the wheel lug torque until it remains within the range described below. Tire size Number of lugs Torque pattern Torque specification 31 X 13.5-15, 8 ply 156 - 183 N m (115 - 135 lb ft) 6 380/55-17, 10 ply 380 - 407 N m (280 - 300 lb ft) 6 480/45-17, 10 ply 380 - 407 N m (280 - 300 lb ft) 6 500/55-20, 10 ply 380 - 407 N m (280 - 300 lb ft) 8 47915813 18/08/2015 27.1 [27.550] / 3

Rear axle system - Non-powered rear axle Rear axle - General specification 1 NHIL13RB00071FA Main gearbox The rear axle connects the spindles and axles of the rear non-powered wheels to the baler frame. The rear axle is adjustable in height and will vary depending on the type of crop processing configuration that is present on the baler. Rear axle Jack points NOTICE: The rear axle has specific jack points at which the baler can be raised. Failure to use the designated jack points when servicing the rear axle can result in irre- versible machine damage. To service the wheels, tires, or axle hubs, rear axle must only be jacked from the designated jack points (1). 2 NHIL13RB00676AA 47915813 18/08/2015 27.1 [27.550] / 4

Rear axle system - Non-powered rear axle Wheel hub - Torque Torque the hardware outlined below to the proper torque specifications. (1) Wheel mount hardware Torque the wheel mount nuts to 164 - 194 N m (121 - 143 lb ft). (2) Spindle hardware Torque the spindle nuts to 164 - 194 N m (121 - 143 lb ft). These torque values are applicable to the wheel hubs of all factory tire sizes. 1 NHIL13RB00986AA 47915813 18/08/2015 27.1 [27.550] / 5

Rear axle system - Non-powered rear axle Rear axle - Exploded view 1 NHIL13RB00070FA Rear axle Exploded view (1) - Bolt, M16 x 100, Class (CL) 8.8 (2) - Nut, M16, CL8 (3) - Locknut, M16, CL8 (4) - Spacer (5) - Bolt. M12 x 45, CL10.9 (6) - Washer, Belleville lock, M12 (7) - Spindle mount, left-hand (8) - Nut, M12, CL10 (9) - Spindle, left-hand (10) - Washer, flat (11) - Bolt, M16 x 100, CL8.8 (12) - Rear axle NOTE: The spindles and spindle mounts are only present on balers equipped with 500/55-20 size wheels and tires. 47915813 18/08/2015 27.1 [27.550] / 6

Rear axle system - Non-powered rear axle Wheel hub - Exploded view NOTE: This wheel hub has eight wheel studs and can be used to mount 500/55 20 size tires. 1 NHIL13RB00776FA 8-stud wheel hub Exploded view (1) - Wheel cap (2) - Nut, castellated, M48 (3) - Bearing (4) - Seal (5) - Hub, 8-stud (6) - Stud, wheel, M18 (7) - Seal (8) - Bearing (9) - Seal (10) - Spindle 47915813 18/08/2015 27.1 [27.550] / 7

Rear axle system - Non-powered rear axle NOTE: This wheel hub has six wheel studs and can be used to mount 380/55 17 and 480/45 17 size tires. 2 NHIL13RB00775FA 6-stud wheel hub Exploded view (1) - Wheel cap (2) - Nut, castellated, M48 (3) - Bearing (4) - Seal (5) - Hub, 6-stud (6) - Stud, wheel, M18 (7) - Seal (8) - Bearing (9) - Seal (10) - Spindle 47915813 18/08/2015 27.1 [27.550] / 8

Rear axle system - Non-powered rear axle NOTE: This wheel hub has six wheel studs and can be used to mount 31x13.5 15 size tires. 3 NHIL13RB00052FA 6-stud wheel hub Exploded view (1) - Spindle (2) - Seal (3) - Bearing (4) - Hub, 6-stud (5) - Bearing (6) - Seal (7) - Wheel cap (8) - Nut, castellated, 1 inch (9) - Pin, cotter, 1/8 inch x 1-1/4 inch 47915813 18/08/2015 27.1 [27.550] / 9

Rear axle system - Non-powered rear axle Rear axle - Remove WARNING Crushing hazard! Unit could fall if not properly supported. Follow jacking instructions provided for the unit. Use suitable jack stands. Be sure to position them properly. Failure to comply could result in death or serious injury. W0919A DANGER Crush hazard! The tailgate may close faster than you can move away. ALWAYS make sure the tailgate lockout valve is engaged in the locked position before working under a raised tailgate. In the event of a sudden loss of hydraulic pressure, the tailgate will fall if the lockout valve is not engaged. Stand clear of the tailgate before disengaging the lockout valve. Failure to comply will result in death or serious injury. D0003B NOTICE: Always make sure that you are making the adjustment on a flat, paved surface, such as a concrete floor. 1. Leave the baler attached to the tractor and apply the tractor parking brake. 2. Remove the bale ramp. See Ejector - Remove - 1.2 m (4 ft) wide bale chamber (70.280). 3. Raise the tailgate, and then engage the tailgate lockout valve (1) by pulling down and then rotating the handle (2) forward. 1 NHIL13RB01858AA 4. If the baler uses a hydraulic or pneumatic braking sys- tem, disconnect the hydraulic hose (1) from the T-fitting on the rear brake axle. 2 NHIL13RB02592AA 47915813 18/08/2015 27.1 [27.550] / 10

Rear axle system - Non-powered rear axle 5. If the baler uses a parking brake, remove the M8 x 30 flange bolt (1) and M8 locknut (2) to disconnect the parking brake cable (3) from each side of the rear brake axle. Figure 3 depicts a baler with 480/45 17 tires. Figure 4 depicts a baler with 500/55 20 tires. NOTE: On balers with 480/45 17 tires, the cable support is between the rear brake axle mounting flanges and above the jacking point. 6. Loosen the jam nut (4) 7. Remove the parking brake sheath from the notch in the cable support (5). 3 NHIL13RB02923AA 8. Cut or otherwise remove the cable ties that secure the parking brake cables to the rear axle. 4 NHIL14RB00208AA 47915813 18/08/2015 27.1 [27.550] / 11

Rear axle system - Non-powered rear axle 9. Using a jack, raise the rear axle high enough to place jack stands (1) under the frame outriggers (2). 10. While continuing to support the rear axle with the floor jack, remove the axle positioning bolts and nuts from each side of the axle flange. 11. Use the floor jack to lower the rear axle so that the tires rest on the ground. 12. Slide the rear axle out and away from the baler. 5 NHIL13RB03089AA 6 NHIL13RB03087AA 7 NHIL13RB03088AA 47915813 18/08/2015 27.1 [27.550] / 12

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

Rear axle system - Non-powered rear axle Rear axle - Adjust The two charts below show the factory axle setting based on the tire size and feeder type. Adjustment should not be necessary, but if it is to be changed, extreme care must be taken to do it safely. NOTICE: Always make sure that you are making the adjustment on a flat, paved surface, such as a concrete floor. Torque the M16 locknuts to 240 N m (177 lb ft). 1 NHIL13RB01053FA Rear axle mounting locations Balers with 31x13.5 15 or 480/45 17 tires Tire size 31x13.5 15 480/45 17 Axle bolt position A, B, C A, B, C Pickup/feeder type ALL ALL 47915813 18/08/2015 27.1 [27.550] / 13

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com