Challenges in Manufacturing Large Machines

Manufacturing large machines poses several challenges such as increased forces and stresses in components, the need for more material handling equipment, decreasing market demand for larger machines in the agriculture sector, higher costs associated with prototyping, and the expenses related to errors and failures.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Agricultural Mechanics and Engineering Ralph Cohen, P.E.

My background Raised on a farm in New Jersey Father graduated from a farm school Poultry and field crops Automatic feeder, egg grader, and egg washer used for egg production Tractor, plow, disk, harrow, seeder, cultivator, combine, corn picker, mower, hay rake, baler, trucks, manure spreader, and wagons all used for field crops (corn, wheat, soy beans, hay primarily) Studied mechanical engineering in college with a thermal systems and machine design specialty Ultimately ended up mostly designing semi-conductor chip factories 2

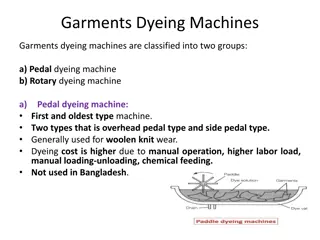

What are the challenges of manufacturing large machines? Manufacturing large anything is challenging! Forces and stresses in components increase with size Need more material handling equipment due to weight Decreasing market for larger machines as farm size decrease 5.6% > 1000 acres (112,000 farms), 2.2% > 2000 acres (44,000 farms) Average farm < 500 acres Building a prototype is more expensive Errors and failures are more expensive 3

Designing Industrial Machinery Short version 1. Product defined by customer (external) or marketing department (internal) 1. Specification prepared (defines form, function, performance) 2. Drawings/sketches may be included and cost budget 2. Design team (engineers, designers) develops several concepts 3. Cost department estimates cost of each completed concept 4. Idea presented to customer who hopefully selects one concept 5. Design team develops prototype and detailed design 6. Prototype fabricated for testing 7. Design is modified after testing 8. Final product fabricated; hopefully within budget 4

Prototype and Custom Machinery Prototype product built with sufficient features to test for proof of concept ; to prove - Functionality of features Durability run to failure or so many cycles Performance speed, fuel consumption, product handled/hour Custom machinery - limited identical units manufactured Low demand Specialized function Higher cost than higher volume product Some manufacturers specialize in custom machinery May still need a prototype 5

What are the challenges unique to building farm equipment? Size bigger over time Tractor hp 40 vs. up to 450 hp today; 2 bottom plow vs. 8 or more today Environment dust, dirt, heat/cold, rain, field conditions (rocks, ruts, mud), pesticides, fertilizers Non-contaminating, especially from lubricants Easy things have already been designed Simple and efficient to operate Low maintenance and easy to repair Operator safe from exposed, moving parts Super reliable Affordable Long life https://www.tstar.com/agriculture-overview 6

ButAg Engineering/Mechanics can be more than machines! Food engineering and the processing of agricultural products Design of agricultural structures Poultry, swine, beef, aquaculture, and plant environmental control Waste management, including animal waste, agricultural residues, and fertilizer runoff Water management, conservation, and storage for crop irrigation and livestock production Utilizing GPS / drones, yield monitoring, remote sensing Worker safety and comfort Efficiency including the control of vibration, noise, air quality, heating, cooling Sales, service, training, management, planning, market and product research https://www.careerexplorer.com/careers/agricultural-engineer/ 7

Education and training required to work in Ag Mechanics? Focuses on agricultural equipment and farm maintenance Practical, hands-on Ag Mechanics courses give you the training you need to maintain and repair equipment vital to agricultural production Work in field and laboratory setting to learn the concepts taught Areas may include: Woodworking, electrical, electronics, plumbing, concrete, hydraulics, HVAC Tractor and farm implement repair Small gas engine-to-large diesel engine repair, powertrains, transmissions Basic welding, metal fabrication, heat treatment Safety and proper use of tools and equipment Equipment management https://www.msun.edu/academics/cots/program-AgMechTech.aspx 8

Education and training required to work in Ag Engineering Calculus, Physics, Chemistry Thermodynamics, Fluids Statics, Mechanics of Materials, Material Science, Dynamics, Ag Structures Surveying, Water and Soil engineering Electricity, Energy, Control Systems, Computer Graphics/CAD Engineering Economics Technical electives including Welding, Mechanical, and Civil Engineering General education courses (non Engineering related) 9

What can students start doing now to be prepared for this field and its future? Learn about future trends, e.g. Self-driving tractors with GPS / remote guidance Use of AI (artificial intelligence) in decisions, e.g. when to plant, harvest, irrigate, etc. Hydroponics (grow in water), water shortage, more efficient irrigation Machines to replace hand picking Get a summer job on a farm Think about an area of specialization Power and machinery engineering Soil and water engineering Post harvest crop processing Farm structures and environmental control engineering Forestry and wood product engineering Consider related fields, e.g. Food Processing Engineering, Biofuels 10

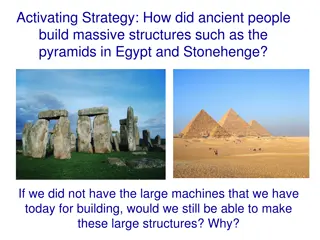

How does what students learn through school tie into this work? What are you learning in school? How do you think it ties into Ag Mechanics or Ag Engineering? 11

What is the most rewarding thing about building farm equipment? In general, we feel good if we are using engineering to design a product or provide a service that is needed by society Farm equipment is essential to food production Farm equipment often improves lives but can eliminate jobs Engineers see their ideas turned into tangible products It isn t enough to design a good product; it also needs to be purchased and be well regarded by the Customers That is success in engineering 12

Facts and figures Ag Engineer salary $45K / $83K / $110K Ag Mechanic salary (Portland, OR) $37K / $46K / $57K Tractor cost Used: $1K to $300K New: $3K to $600K Combine cost Used: $6K to $450K New: $330K to $500K 14