Classification of Casting Processes

Casting processes are classified into categories such as conventional molding, permanent mold, special casting, and chemical sand molding processes. One of the special casting processes, Investment Casting, involves creating wax patterns, assembling them, covering with refractory slurry, melting the pattern, firing, pouring, and finishing. Another method, Ceramic Shell Investment Casting, differs in that a ceramic shell is built around the pattern assembly before the metal is poured. This process includes building up the shell, burning out residual wax, and storing or immediately using the shell molds for metal pouring.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

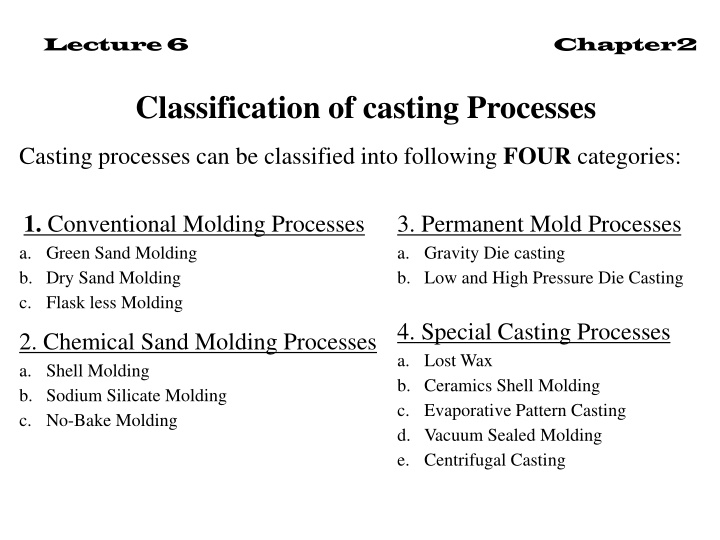

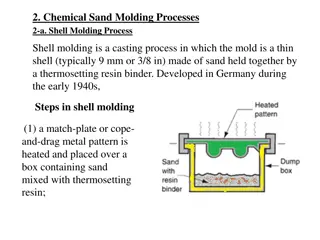

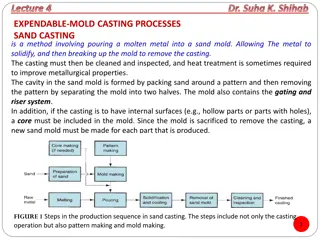

Lecture 6 Chapter2 Classification of casting Processes Casting processes can be classified into following FOUR categories: 1. Conventional Molding Processes a. Green Sand Molding b. Dry Sand Molding c. Flask less Molding 3. Permanent Mold Processes a. Gravity Die casting b. Low and High Pressure Die Casting 4. Special Casting Processes a. Lost Wax b. Ceramics Shell Molding c. Evaporative Pattern Casting d. Vacuum Sealed Molding e. Centrifugal Casting 2. Chemical Sand Molding Processes a. Shell Molding b. Sodium Silicate Molding c. No-Bake Molding

4. Special Casting Processes 4-a. Investment Casting Process(lost wax) The root of the investment casting process, lost wax method dates back to at least the fourth millennium B.C. The artists and sculptors of ancient Egypt and Mesopotamia used the rudiments of the investment casting process to create intricately detailed jewelry, pectorals and idols. The investment casting process also called lost wax process begins with the production of wax replicas or patterns of the desired shape of the castings. A pattern is needed for every casting to be produced. The patterns are prepared by injecting wax or polystyrene in a metal dies. A number of patterns are attached to a central wax sprue to form a assembly. The mold is prepared by surrounding the pattern with refractory slurry that can set at room temperature. The mold is then heated so that pattern melts and flows out, leaving a clean cavity behind. The mould is further hardened by heating and the molten metal is poured while it is still hot. When the casting is solidified, the mold is broken and the casting taken out.

The basic steps of the investment casting process 1. Production of heat-disposable wax, plastic, or polystyrene patterns 2- Assembly of these patterns onto a gating system 3-Investing, or covering the pattern assembly with refractory slurry

4-Melting the pattern assembly to remove the pattern material 5- Firing the mold to remove the last traces of the pattern material 6-Pouring 7- Cut off and finishing.

4-b. Ceramic Shell Investment Casting Process The basic difference in investment casting is that in the investment casting the wax pattern is immersed in a refractory aggregate before dewaxing whereas, in ceramic shell investment casting a ceramic shell is built around a tree assembly by repeatedly dipping a pattern into a slurry (refractory material such as zircon with binder). After each dipping and stuccoing is completed, the assembly is allowed to thoroughly dry before the next coating is applied. Thus, a shell is built up around the assembly. The thickness of this shell is dependent on the size of the castings and temperature of the metal to be poured. After the ceramic shell is completed, the entire assembly is placed into an autoclave or flash fire furnace at a high temperature. The shell is heated to about 982 Co to burn out any residual wax and to develop a high- temperature bond in the shell. The shell molds can then be stored for future use or molten metal can be poured into them immediately. If the shell molds are stored, they have to be preheated before molten metal is poured into them.

Advantages excellent surface finish tight dimensional tolerances machining can be reduced or completely eliminated

4-c. Expanded Polystyrene Process / Evaporative Pattern Casting Process The expanded polystyrene casting process uses a mold of sand packed around a poly-styrene foam pattern that vaporizes when the molten metal is poured into the mold. The process and variations of it are known by other names, including lost-foam process, lost-pattern process, evaporative-foam process, and full-mold process (the last being a trade name). The foam pattern includes the sprue, risers, and gating system, and it may also contain internal cores (if needed), thus eliminating the need for a separate core in The mold . Also, since the foam pattern itself becomes the cavity in the mold, considerations of draft and parting lines can be ignored. The mold does not have to be opened into cope and drag sections. The sequence in this casting process is illustrated and described in Figure 9.1. Various methods for making the pattern can be used, depending on the quantities of castings to be produced. For one-of-a-kind castings, the foam is manually cut from large strips and assembled to form the pattern. For large production runs, an automated molding operation can be set up to mold the patterns prior to making the molds for casting.

The pattern is normally coated with a refractory compound to provide a smoother surface on the pattern and to improve its high temperature resistance. Molding sands usually include bonding agents. However, dry sand is used in certain processes in this group, which aids recovery and reuse. A significant advantage for this process is that the pattern need not be removed from the mold. This simplifies and expedites mold making. In a conventional green-sand mold, two halves are required with proper parting lines, draft allowances must be provided in the mold design, cores must be inserted, and the gating and riser system must be added. With the expanded polystyrene process, these steps are built into the pattern itself. A new pattern is needed for every casting, so the economics of the expanded polystyrene casting process depend largely on the cost of producing the patterns. The process has been applied to mass produce castings for automobiles engines. Automated production systems are installed to mold the polystyrene foam patterns for these applications

The expanded polystyrene casting Procedure (1) pattern of polystyrene is coated with refractory compound; (2) foam pattern is placed in mold box, and sand is compacted around the pattern; and (3) molten metal is poured into the portion of the pattern that forms the pouring cup and sprue. As the metal enters the mold, the polystyrene foam is vaporized ahead of the advancing liquid, thus allowing the resulting mold cavity to be filled.