Coagulation in Water Treatment

Coagulation is a vital chemical treatment process used to destabilize colloidal particles in water, aiding in the removal of suspended solids. By adding a coagulant, such as metal salts, the process of charge neutralization occurs, leading to the formation of larger particles that can be easily removed. The characteristics of colloidal particles, including their size and charge, play a key role in the effectiveness of coagulation. Rapid mixing through mechanical mixers is essential to disperse the chemicals evenly in the water, optimizing the coagulation process.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

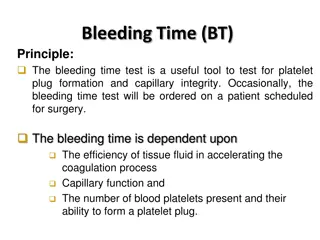

Water from a natural source usually contains suspended solids which fall in a wide size spectrum. Typical size of particleate found in surface water are listed in the table below:

Masterial Particle diameter Viruses 0. 005 0.01 Bacteria 0.3 3.0 Small colloids 0.001 0.1 Large colloids 0.1 - 1 Soil 1 -100

Characteristics of colloidals Colloidal particles size is generally less than 1 micron. Such as clay, silt, bacteria and viruses. Generally colloids in natural water vhave negative charge. Because these colloids have the same charge they will repel each other.

Repulsion due to electrical charge will normally repel the colloids before they can move close. If the magnitude of electrical of the electrical force could be reduced, the particle woud move close enough for van der walls forces to predominate.

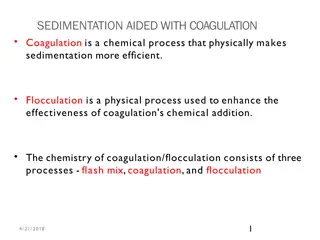

Coagulation: is a chemical treatment process used to destabilize colloidal particles Coagulant is a chemical that is added to the water to achieve coagulation process.

Traditionalyy, metal salts as aluminium sulfate , ferric sulfate have been utilized as coagulant The most important mechanism to achieve coagulant is charge neutralization which means that the positive aluminium ions are absorbed on the negatively charged colloids.

Rapid mixer should provide suffisient agitation to disperse the chemical theoretically in the water. Rapid mixer utilize mechanical mixer are usually square and have a depth to width ratio of approximately 2

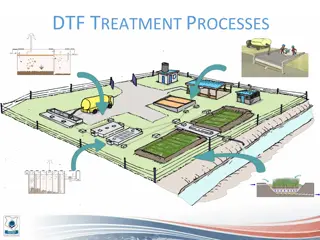

11.0 Rapid Mixing After aeration, the aerated water will flows into rapid mixing tanks. For effective rapid mixing, the dosing of liquid alum will be positioned just at the inlet chamber of the mixing tank. The dosing of liquid alum will be proportioned to the rate of raw water flow. Signal of raw water flow will be taken from the raw (aerated) water flowmeter which will be installed at the common raw (aerated) water outlet pipe in between the aeration tank and the mixing tank.

12.0 Design of Flash Mixer = 250s-1 to 1000s-1 Flash Mixer Velocity Gradient Adopt = 400s-1 Design Velocity Gradient, G Retention Time = 90 seconds = 3500 m3/h x 90s 60 x 60 Volume = 87.5m3

43.75m3 Provide 2 tanks V1 = Propose Depth = 3.6m B1 = 3.5m L = 3.5m Flocculation G = P V

Where P= Power Input V = Volume of Tank = Absolute viscosity, 0.00086 Ns/m2 at 27oC P= G2 x V = (400s-1)2 (44.1) (0.00086 Ns/m2) = 6,068 watts = 6.1 kW mixer