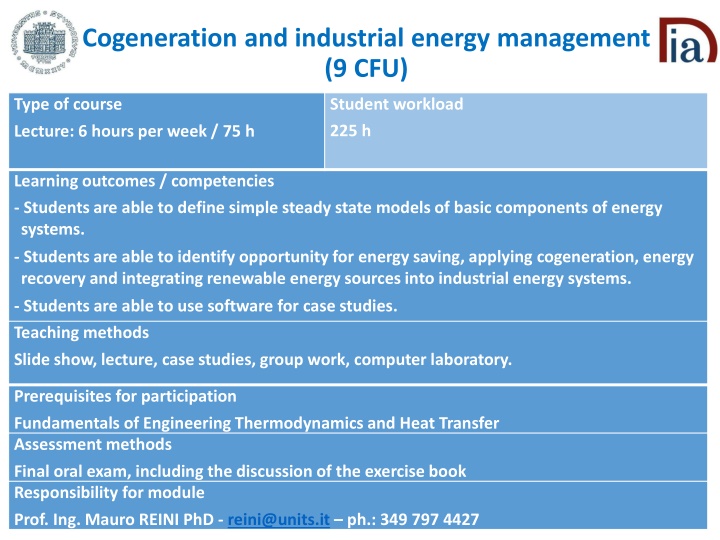

Cogeneration and Industrial Energy Management Course Overview

This course covers steady-state modeling of industrial energy systems, exergy analysis, thermoeconomic methods, introduction to solar energy systems, and combined heat and power systems. Students will learn about energy saving opportunities, cogeneration, and integrating renewable energy sources into industrial energy systems. The teaching methods include lectures, case studies, group work, and computer laboratory sessions. Prerequisites include fundamentals of engineering thermodynamics and heat transfer. Assessment is through a final oral exam. Taught by Prof. Ing. Mauro Reini, Ph.D.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Cogeneration and industrial energy management (9 CFU) Type of course Student workload 225 h Lecture: 6 hours per week / 75 h Learning outcomes / competencies - Students are able to define simple steady state models of basic components of energy systems. - Students are able to identify opportunity for energy saving, applying cogeneration, energy recovery and integrating renewable energy sources into industrial energy systems. - Students are able to use software for case studies. Teaching methods Slide show, lecture, case studies, group work, computer laboratory. Prerequisites for participation Fundamentals of Engineering Thermodynamics and Heat Transfer Assessment methods Final oral exam, including the discussion of the exercise book Responsibility for module Prof. Ing. Mauro REINI PhD - reini@units.it ph.: 349 797 4427

1. STEADY 1. STEADY- -STATE STATE MODELLING MODELLING of industrial energy systems of industrial energy systems Industrial Energy systems components Pipes and nozzles Energy conservation principle, pressure losses, Moody diagram, Mach number, sub-sonic / super-sonic nozzles, irreversibility and entropy, isentropic flow, efficiency. Heat exchangers T-Q diagram, e-NTU method, off-design operation. Fluid machines and Turbomachines Classification and operating modes, Thermodynamic cycles and the T-s diagram, Euler theorem, Turbomachines no- dimension parameters and characteristic curves. Working fluids Ideal gas, incompressible fluids, real fluids, mixture. Modeling multi-component energy systems Equation based model, EES software, module based simulation software, application to gas and steam power plants.

2. EXERGY AND THERMOECONOMIC ANALYSIS 2. EXERGY AND THERMOECONOMIC ANALYSIS Exergy Exergy function definition, ambient reference, Guy-Stodola theorem, Exergy Analysis of elementary processes, thermodynamic cycles, mixing and chemical processes, Energy and Exergy Analysis of energy plants and production processes. Thermoeconomics Second low based Thermoeconomic methods, Costing of multi-product / multi-component systems, Local optimization of plant components, Industrial ecology.

3. 3. INTRODUCTION TO SOLAR ENERGY SYSTEMS INTRODUCTION TO SOLAR ENERGY SYSTEMS Solar radiation Photovoltaic plants Photoelectric effect, Solar cell materials, Modules and plant balance. Solar thermal system Solar flat collectors and tubes, Solar concentrators, Solar thermal plants and heat storage. Solar systems economic evaluation

4. 4. COMBINED HEAT AND POWER (CHP) COMBINED HEAT AND POWER (CHP) Thermodynamic benefits of CHP CHP systems overview and performance parameters, Energy user s profiles, Environmental and economic evaluation, Optimal operation of CHP plants with MILP Techniques, The choice of CHP technology Steam and Rankine CHP plants, Gas turbine based CHP plants, Internal combustion engine based CHP plants, Tri-generation Absorption cooling cycles, the p-T diagram, Absorption chillers, Tri-generation plants.

REFERENCES REFERENCES Thermal Design and Optimization Adrian Bejan, Duke Univ. George Tsatsaronis, Technische Univ. Berlin Michael Moran, The Ohio State Univ. John Wiley & Sons, c1996 EES (Engineering Equation Solver) Manual S.A. Klein F-Chart Software, 2009 Combined Heating, Cooling and Power Handbook Neil Petchers Taylor & Francis, Inc., November 2003 Fluid Mechanics and Thermodynamics of Turbomachinery Dixon S.L. Butterworth Heinemann, 1998 La microcogenerazione a gas naturale E. Macchi et al. polipress, Milano 2005 Turbine a gas e cicli combinati G. Lozza Progetto Leonardo, Esculapio Editore (BO) 2015