Combining Reactions for Overall Reaction Analysis

This exercise involves combining three individual reactions to determine the overall reaction. Follow along as species are matched in the reactions, leading to the formation of the combined reaction. Additionally, errors in a process flow diagram are identified and corrected, focusing on compound melting and boiling points. Explore the synthesis reactors, separators, mixers, and purges involved in the chemical processes.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Calculation Session 1 Exercise 2.9 Created by: Angela Tang ( 18) Edited by: Olivia Young ( 19), Ellen Park ( 20), Andrew Simon ( 21), Kelsey Levine ( 22), Lucy Cadanau ( 22), Ariel Struzyk ( 23), Burke Combs ( 24), and Ashlyn Dumaw ( 25)

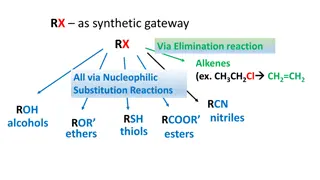

Goal: A) Combine the three reactions to get the overall reaction Info: Three individual reactions and the overall reaction Where to start: Match species in the overall reaction to the individual reactions

A) Combining Reactions C + 2S CS2 CS2+ 3Cl2 S2Cl2+ CCl4 CS2+ 2S2Cl2 6S + CCl4 C + 2Cl2 CCl4

A) Combining Reactions C + 2S CS2 CS2+ 3Cl2 S2Cl2+ CCl4 CS2+ 2S2Cl2 6S + CCl4 C + 2Cl2 CCl4

A) Combining Reactions C + 2S CS2 1x 2 3x CS2+ 3Cl2 S2Cl2+ CCl4 1 3x CS2+ 2S2Cl2 6S + CCl4 C + 2Cl2 CCl4

A) Combining Reactions C + 2S CS2 2 3CS2+ 2Cl2 2 1 3CS2+ 2 3S2Cl2+ 2 3CCl4 3S2Cl2 2S + 1 3CCl4 C + 2Cl2 CCl4

Goal: B) Correct errors in the process flow diagram Info: A provided process flow diagram (PFD) Compound melting and boiling points Where to start: 1) Check the overall reaction 2) Check individual reactions/separators 3) Check the logic of the diagram

(B) C C S makeup: S carbon disulfide synthesis reactor 800 C CS2 S mixer CS2 CS2 Cl2 CS2 Cl2 S2Cl2 CCl4 CS2 Cl2 CCl4 CS2 Cl2 carbon tetrachloride synthesis reactor I, 130 C liquid-gas separator 60 C CCl4 Error 1 Error 1 S2Cl2 CCl4 S2Cl2 CCl4 liquid-gas separator 155 C Error 2 Error 2 purge Error 3 Error 3 S2Cl2 CS2 CS2 S2Cl2 CCl4 CS2 Error 4 Error 4 CS2 S2Cl2 CCl4 S liquid-gas separator 60 C Error 5 Error 5 CS2 S2Cl2 carbon tetrachloride synthesis reactor II, 60 C solid-gas separator 150 C S2Cl2 CCl4 S purge purge

(B) C C S makeup: S carbon disulfide synthesis reactor 800 C CS2 S 3C + 6Cl2 3CCl4 mixer CS2 CS2 Cl2 Cl2 CS2 Cl2 S2Cl2 CCl4 CS2 Cl2 CCl4 CS2 Cl2 carbon tetrachloride synthesis reactor I, 130 C liquid-gas separator 60 C CCl4 Return Return S2Cl2 CCl4 S2Cl2 CCl4 liquid-gas separator 155 C purge S2Cl2 CS2 CS2 S2Cl2 CCl4 CS2 CS2 S2Cl2 CCl4 S liquid-gas separator 60 C CS2 S2Cl2 carbon tetrachloride synthesis reactor II, 60 C solid-gas separator 150 C S2Cl2 CCl4 S purge purge

(B) C C S makeup: S CS2 carbon disulfide synthesis reactor 800 C CS2 S mixer CS2 CS2 Cl2 CS2 Cl2 S2Cl2 CCl4 CS2 Cl2 CCl4 CS2 Cl2 carbon tetrachloride synthesis reactor I, 130 C liquid-gas separator 60 C CCl4 Return Return S2Cl2 CCl4 S2Cl2 CCl4 liquid-gas separator 155 C purge S2Cl2 CS2 CS2 S2Cl2 CCl4 CS2 CS2 S2Cl2 CCl4 S liquid-gas separator 60 C CS2 S2Cl2 carbon tetrachloride synthesis reactor II, 60 C solid-gas separator 150 C S2Cl2 CCl4 S purge CS2+ 2S2Cl2 6S + CCl4 purge

(B) C C S makeup: S carbon disulfide synthesis reactor 800 C CS2 S mixer CS2 CS2 Cl2 purge CS2 Cl2 S2Cl2 CCl4 CS2 Cl2 CCl4 CS2 Cl2 carbon tetrachloride synthesis reactor I, 130 C liquid-gas separator 60 C CCl4 Return Return S2Cl2 CCl4 S2Cl2 CCl4 liquid-gas separator 155 C purge S2Cl2 CS2 CS2 S2Cl2 CCl4 CS2 CS2 S2Cl2 CCl4 S liquid-gas separator 60 C CS2 S2Cl2 carbon tetrachloride synthesis reactor II, 60 C solid-gas separator 150 C S2Cl2 CCl4 S purge purge

(B) C C S makeup: S carbon disulfide synthesis reactor 800 C CS2 S mixer CS2 CS2 Cl2 CS2 Cl2 S2Cl2 CCl4 CS2 Cl2 CCl4 Do our CS2 Cl2 carbon tetrachloride synthesis reactor I, 130 C liquid-gas separator 60 C separators check out? CCl4 Return Return S2Cl2 CCl4 S2Cl2 CCl4 liquid-gas separator 155 C purge T=60 C Cl2 -35 -101 S2Cl2 CS2 CS2 S2Cl2 CCl4 -111 CS2 46 CS2 CS2 S2Cl2 CCl4 S S2Cl2 liquid-gas separator 60 C -23 77 CCl4 CS2 S2Cl2 carbon tetrachloride synthesis reactor II, 60 C 136 -80 solid-gas separator 150 C S2Cl2 CCl4 113 S purge S purge C

(B) C C S makeup: S carbon disulfide synthesis reactor 800 C CS2 S mixer CS2 CS2 Cl2 CS2 Cl2 S2Cl2 CCl4 CS2 Cl2 CCl4 CS2 Cl2 carbon tetrachloride synthesis reactor I, 130 C liquid-gas separator 60 C CCl4 Return Return S2Cl2 CCl4 S2Cl2 CCl4 liquid-gas separator 155 C purge T=155 C T=105 C Cl2 -35 -101 S2Cl2 T=105 C CS2 CS2 S2Cl2 CCl4 -111 S2Cl2and CCl4are both gases. Cannot separate! 46 CS2 CS2 CS2 S2Cl2 CCl4 S S2Cl2 liquid-gas separator 60 C -23 77 CCl4 CS2 S2Cl2 carbon tetrachloride synthesis reactor II, 60 C 136 -80 solid-gas separator 150 C S2Cl2 CCl4 113 S purge S purge C

(B) C C S makeup: S carbon disulfide synthesis reactor 800 C T=150 C Cl2 -35 -101 CS2 S mixer -111 CS2 46 CS2 CS2 Cl2 -23 77 CCl4 CS2 Cl2 S2Cl2 CCl4 CS2 Cl2 CCl4 136 -80 S2Cl2 CS2 Cl2 carbon tetrachloride synthesis reactor I, 130 C liquid-gas separator 60 C 113 CCl4 S Return Return S2Cl2 CCl4 S2Cl2 CCl4 C liquid-gas separator 155 C purge S2Cl2 CS2 CS2 S2Cl2 CCl4 CS2 Liquid-gas separator CS2 S2Cl2 CCl4 S liquid-gas separator 60 C CS2 S2Cl2 carbon tetrachloride synthesis reactor II, 60 C solid-gas separator 150 C S2Cl2 CCl4 S purge purge

(B) C C S makeup: S CS2 carbon disulfide synthesis reactor 800 C CS2 S mixer CS2 CS2 Cl2 purge Cl2 CS2 Cl2 S2Cl2 CCl4 CS2 Cl2 CCl4 CS2 Cl2 carbon tetrachloride synthesis reactor I, 130 C liquid-gas separator 60 C CCl4 CS2 S2Cl2 CCl4 S2Cl2 CCl4 liquid-gas liquid-gas separator 155 C separator 105 C purge S2Cl2 CS2 CS2 S2Cl2 CCl4 CS2 CS2 S2Cl2 CCl4 S liquid-gas separator 60 C CS2 S2Cl2 carbon tetrachloride synthesis reactor II, 60 C liquid-gas solid-gas separator 150 C separator 150 C S2Cl2 CCl4 S purge purge

Key Takeaways What Did We Learn? Overall process agrees with overall reaction (Error #1) Check the overall process by tracing the path (Error #2) Every recycle needs a purge to remove impurities (Error #3) Use visuals to double check physical states and temperatures (Error #4 & Error #5)