Comparative Study of EV Batteries and Charging Methods

This comparative study delves into the characteristics, advancements, reactions, and future directions of lithium-ion, lithium-air, and lithium-sulfur batteries. Exploring metrics for evaluating EV batteries, it highlights the goals set by the US Advanced Battery Consortium for commercialization by 2020. The study also covers the importance of specific energy, specific power, cycle life, safety, cost, and charging speed in assessing EV batteries. Additionally, it provides insights into the developments in Li-air batteries, emphasizing theoretical specific energy and key reactions.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

EV Batteries: A Comparative Study of Batteries and Charging Methods Matt Rohde

Summary of Slides 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Li-ion battery characteristics 11. Li-ion recent advancements Metrics what are the goals Metrics how the goals apply to EVs Li-air reactions and visual Li-air battery characteristics Li-air recent advancements Li-S reaction and visual Li-S battery characteristics Li-S recent advancements Li-ion reactions and visual 12. Where are the batteries headed 13. Charging categories 14. On-board vs off-board chargers 15. Slow charging 16. Accelerated charging 17. Fast charging 18. Where are the chargers headed

Metrics How Should We Evaluate EV Batteries US Advanced Battery Consortium has laid out goals for commercialization by 2020 Evaluation points include: energy density, power density, cycle life, safety, cost, and charging speed.

USABCs Goals Table 1: USABC Goals for Advanced Batteries for EVs CY 2020 Commercialization1 End of Life Characteristics at 30 C Units System Level Cell Level Peak Discharge Power Density, 30 s Pulse W/L 1000 1500 Peak Specific Discharge Power, 30 s Pulse W/Kg 470 700 Useable Energy Density @ C/3 Discharge Rate Wh/L 500 750 Useable Specific Energy @ c/3 Discharge Rate Wh/kg 235 350 DST Cycle Life Cycles 1000 1000 Selling Price @ 100K units $/kWh 125 100 Normal Recharge Time Hours <7 Hours <7 hours High Rate Charge Minutes 80% in 15 min 80% in 15 min

What does it mean? Specific Energy: Wh/kg. Related to the vehicle s range. Specific Power: W/kg. How fast can the vehicle accelerate. Cycle Life: How many full charge/discharge cycles the battery can go through and still operate properly Safety: Are there any risks outside of driver error? Cost: $/kWh. Not something readily published. Charging speed: how quickly can the battery charge?

Li-Air Reactions and Visual Non-aqueous batteries: 2Li + O2 Aqueous batteries: 2Li+ 2e + O2 + H2O Li2O2 2LiOH FIG 1: Li-air schematic39

Li-Air Batteries Lithium anode and O2 or air cathode Theoretical specific energy: 11,680 Wh/kg Gasoline just over 13,000 Wh/kg Practical specific energy estimates: 900 Wh/kg 1,700 Wh/kg USABC s goal is 235 Wh/kg Poor specific power supercapacitor necessary Safety issues still pose large concerns internal shorts, explosions, anode degradation from moisture and water Cycle life 50 to 200 cycles. Many Li-ion batteries well over 300 cycles Cost: $500/kWh Implementation still 10+ years out

Comparison of Theoretical Specific Energy FIG 2: Comparison of theoretical vs practical energy density39

Li-Air Recent Advancements Self healing electrostatic shields Metal cations such as Rubidium are inserted into the electrolyte Occupy spaces where lithium would form dendrites and forces lithium to go elsewhere Promotes even lithium formation during recharge

Li-S Reaction and Visual Reaction: S8 + 16Li 8Li2S FIG 4: Li-S schematic32

Li-S Batteries Theoretical specific energy: 2,500 Wh/kg; Practical: 600 Wh/kg Well past USABC s goal of 235 Wh/kg Specific power: 300 - 1,500 W/kg USABC s goal: 470 Cycle life issues: Lithium polysulfides insulate anode, cathode, and dissolve in electrolyte to reduce capacity Wide range of cycles anywhere from 50 to 200+ Oxis Energy - developing a 165 Wh/kg and 1500 cycle battery Saft Energy 500 Wh/kg 500 cycle battery Safety issues: similar to Li-air. Dendrites/shorts/explosions Solid electrolytes seem to be a solution to this Cost: $300/kWh USABC s goal: $125/kWh

Li-S Recent Advancements Carbon interlayers Currently Li-S batteries suffer from poor cycle life and capacity fade Major issue is that Li2S2 or Li2S do not form right away in cathode Li2S8 or Li2S6 Are formed first these are soluble and will traverse between cathode, electrolyte, and anode As soon as Li2S8 or Li2S6 reach the anode, they will react with lithium and precipitate to form Li2S2 or Li2S Reaction is not reversible and capacity is permanently lost Solution is to add carbon interlayer to strain out polysulfides

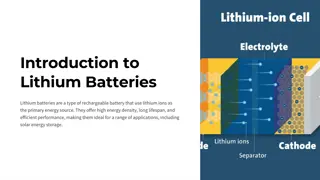

Li-ion Reactions and Visual Many different kinds of li-ion batteries and reactions Lithium cobalt oxide: LiCoO2 + C6 Lithium iron phosphate: LiFePO4 + 6C lithium manganese dioxide: LiMn2O4 FIG 6: Li-ion schematic17 Li1-xCoO2 + C6LX LiC6 + FePO4 Li1-xMn2O4 + xLi+ + xe-

Li-ion batteries Variety of anode/cathode combinations Maximum specific energy projections: 250 Wh/kg USABC s goal is 235 Wh/kg Maximum specific power projections: 400-600 W/kg USABC s goal: 470 W/kg Safety issues still a concern for automotive applications Cycle life projections: close to 3,000. Well surpass USABC s goal of 1,000 Cost: $300/kWh

Li-ion Advancements Silicon is considered a future electrode because they enhance battery capacity Silicon also expands during lithiation/recharging and will cause the electrode to crumble Silicon monoxide has been used to reduce expansion from 280% to 160%

Where are the Batteries Headed Probably no silver bullet for EVs. Compromise will be necessary Cost is a universal issue for all batteries Continue developing Li-ion batteries Prioritize commercialization now focus on Li-S batteries for the mid-term Li-Air for the long term

Charging Categories On-board vs off-board charging On-board charging method is internal to the vehicle. Usually a plug within the vehicle Off-board External connector that plugs into the vehicle Rate of charge Slow charging/Type 1 Accelerated charging/Type 2 Fast charging/Type 3

On-Board and Off-Board Characteristics On-board charging characteristics: Flexibility charge wherever an outlet is present Power delivered to the vehicle and charging speed is typically lower type 1 or 2 Off-board charging characteristics: Charging tied to wherever a station is Power delivered to vehicle and charging speed are higher

Slow Charging/Type 1 Power output: ~ 3 kW Voltage: 120 V Full charge: 6-8 hours 80% Charge: 3-4 hours Installation cost: $500-$800 Approximately 52% of households are renters - Low cost could enable implementation on city blocks

Accelerated Charging/Type 2 Power output: 7 - 43 kW Voltage: 208 240 V On and off-board Full charge: 1 hour 80% Charge: 30 minutes Installation cost: $1,000 - $3,000 Well suited for errands/routine tasks grocery shopping, malls, appointments, gyms, etc.

Fast Charging/Type 3 Power output: 50 - 250 kW Voltage: 480 V Exclusively off-board Full charge: 5 -25 minutes Installation cost: $30,000 - $160,000 No practical application

Charging Solutions Moving Forward Enable widescale charging network via slow and accelerated chargers More chargers on rental properties, city blocks, and public spaces More chargers may generate demand for EVs Facilitate development of better batteries and chargers

References References 1. http://www.uscar.org/guest/article_view.php?articles_id=85. 2. Lin, D., Liu, Y. & Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nature Nanotechnology 12, 194-206 (2017). 3. Li, W. & Goodman, L. Comparing Credit Profiles of American Renters and Owners. Washington, DC: Urban Institute.http://urbn.is/29FqJOx (2016). 4. Yilmaz, M. & Krein, P. T. Review of battery charger topologies, charging power levels, and infrastructure for plug-in electric and hybrid vehicles. IEEE Transactions on Power Electronics 28, 2151-2169 (2013). 5. Reddy, A. L. M. et al. Synthesis of nitrogen-doped graphene films for lithium battery application. ACS nano 4, 6337-6342 (2010). 6. Mahmood, N., Tang, T. & Hou, Y. Nanostructured anode materials for lithium ion batteries: progress, challenge and perspective. Advanced Energy Materials 6 (2016). 7. Hosono, E., Kudo, T., Honma, I., Matsuda, H. & Zhou, H. Synthesis of single crystalline spinel LiMn2O4 nanowires for a lithium ion battery with high power density. Nano letters 9, 1045-1051 (2009). 8. Oswal, M., Paul, J. & Zhao, R. A comparative study of Lithium-Ion Batteries. USA: University of Southen California (2010). 9. Chen, T., Wu, J., Zhang, Q. & Su, X. Recent advancement of SiOx based anodes for lithium-ion batteries. J. Power Sources 363, 126-144 (2017). 10. Kolosnitsyn, V. S. & Karaseva, E. V. Lithium-sulfur batteries: Problems and solutions. Russian J. Electrochem. 44, 506-509 (2008). 11. Cheng, X. et al. Polysulfide shuttle control: Towards a lithium-sulfur battery with superior capacity performance up to 1000 cycles by matching the sulfur/electrolyte loading. J. Power Sources 253, 263-268 (2014). 12. Nazar, L. F., Cuisinier, M. & Pang, Q. Lithium-sulfur batteries. MRS Bull 39, 436-442 (2014).

References 13. Lochala, J., Liu, D., Wu, B., Robinson, C. & Xiao, J. Research Progress Towards the Practical Applications of Lithium Sulfur (Li-S) Batteries. ACS Applied Materials & Interfaces (2017). 14. Ji, X., Lee, K. T. & Nazar, L. F. A highly ordered nanostructured carbon sulphur cathode for lithium sulphur batteries. Nature materials 8, 500-506 (2009). 15. Evarts, E. C. Lithium batteries: To the limits of lithium. Nature 526, S95 (2015). 16. Tie, S. F. & Tan, C. W. A review of energy sources and energy management system in electric vehicles. Renewable and Sustainable Energy Reviews 20, 82- 102 (2013). 17. Crabtree, G., Kcs, E. & Trahey, L. The energy-storage frontier: Lithium-ion batteries and beyond. MRS Bull 40, 1067-1078 (2015). 18. Gerssen-Gondelach, S. J. & Faaij, A. P. Performance of batteries for electric vehicles on short and longer term. J. Power Sources 212, 111-129 (2012). 19. Akridge, J. R., Mikhaylik, Y. V. & White, N. Li/S fundamental chemistry and application to high-performance rechargeable batteries. Solid State Ionics 175, 243-245 (2004). 20. Mikhaylik, Y. V. et al. High energy rechargeable Li-S cells for EV application: status, remaining problems and solutions. Ecs Transactions 25, 23-34 (2010). 21. Kang, W. et al. A review of recent developments in rechargeable lithium-sulfur batteries. Nanoscale 8, 16541-16588 (2016). 22. Gopalakrishnan, R. et al. A Comprehensive Study on Rechargeable Energy Storage Technologies. 23. Christensen, J. et al. A Critical Review of Li/Air Batteries. J. Electrochem. Soc. 159, R30 (2011). 24. Bruce, P. G., Freunberger, S. A., Hardwick, L. J. & Tarascon, J. Li-O2 and Li-S batteries with high energy storage. Nat Mater 11, 19-29 (2012).

References 25. Zhang, Q., Deng, W., Zhang, S. & Wu, J. in A Rule Based Energy Management System of Experimental Battery/Supercapacitor Hybrid Energy Storage System for Electric Vehicles 1-17, 2016). 26. Manthiram, A., Chung, S. & Zu, C. Lithium Sulfur Batteries: Progress and Prospects. Adv Mater 27, 1980-2006 (2015). 27. Urbonaite, S., Poux, T. & Nov k, P. Progress Towards Commercially Viable Li S Battery Cells. Advanced Energy Materials 5, n/a (2015). 28. Lang, J., Qi, L., Luo, Y. & Wu, H. High performance lithium metal anode: Progress and prospects. Energy Storage Materials 7, 115-129 (2017). 29. Demir-Cakan, R. et al. Li-S batteries: simple approaches for superior performance. Energy Environ. Sci. 6, 176-182 (2013). 30. Li, J. et al. Toward Low-Cost, High-Energy Density, and High-Power Density Lithium-Ion Batteries. JOM 69, 1484-1496 (2017). 31. Kraytsberg, A. & Ein-Eli, Y. Review on Li air batteries Opportunities, limitations and perspective. J. Power Sources 196, 886-893 (2011). 32. Evers, S. & Nazar, L. F. New Approaches for High Energy Density Lithium Sulfur Battery Cathodes. Acc. Chem. Res. 46, 1135-1143 (2013). 33. Rahman, M. A., Wang, X. & Wen, C. A review of high energy density lithium air battery technology. J. Appl. Electrochem. 44, 5-22 (2014). 34. Jung, H., Hassoun, J., Park, J., Sun, Y. & Scrosati, B. An improved high-performance lithium air battery. Nat Chem 4, 579-585 (2012). 35. Vanek, F. M., Angenent, L. T., Banks, J. H., Daziano, R. A. & Turnquist, M. A. in Sustainable Transportation Systems Engineering (McGraw Hill Professional, Access Engineering, 2014). 36. Vanek, F. M., Albright, L. D. & Angenent, L. T. in Energy Systems Engineering: Evaluation and Implementation, Third Edition (McGraw Hill Professional, Access Engineering, 2008). 37. Wayne Beaty, H. & Fink, D. G. in Standard Handbook for Electrical Engineers, Sixteenth Edition (McGraw Hill Professional, Access Engineering, 2013). 38. Reddy, T. B. in Linden s Handbook of Batteries, Fourth Edition (McGraw Hill Professional, Access Engineering, 1984).

References 39. Girishkumar, G., McCloskey, B., Luntz, A. C., Swanson, S. & Wilcke, W. Lithium Air Battery: Promise and Challenges. J. Phys. Chem. Lett. 1, 2193-2203 (2010). 40. Liu, T. et al. Cycling Li-O(2) batteries via LiOH formation and decomposition. Science 350, 530-533 (2015). 41. Anse n, D. et al. Fast charging technique for high power lithium iron phosphate batteries: A cycle life analysis. Journal of Power Sources 239, 9-15 (2013). 42. Omar, N. et al. Lithium iron phosphate based battery Assessment of the aging parameters and development of cycle life model. Applied Energy 113, 1575- 1585 (2014). 43. Ellis, B. L. & Nazar, L. F. Sodium and sodium-ion energy storage batteries. Current Opinion in Solid State and Materials Science 16, 168-177 (2012). 44. Scrosati, B. & Garche, J. Lithium batteries: Status, prospects and future. Journal of Power Sources 195, 2419-2430 (2010). 45. Zhu, W. H., Zhu, Y., Davis, Z. & Tatarchuk, B. J. Energy efficiency and capacity retention of Ni MH batteries for storage applications. Applied Energy 106, 307-313 (2013). 46. Kang, J., Yan, F., Zhang, P. & Du, C. Comparison of comprehensive properties of Ni-MH (nickel-metal hydride) and Li-ion (lithium-ion) batteries in terms of energy efficiency. Energy 70, 618-625 (2014). 47. Hannan, M. A., Hoque, M. M., Mohamed, A. & Ayob, A. Review of energy storage systems for electric vehicle applications: Issues and challenges. Renewable and Sustainable Energy Reviews 69, 771-789 (2017). 48. Sujitha, N. & Krithiga, S. RES based EV battery charging system: A review. Renewable and Sustainable Energy Reviews 75, 978-988 (2017). 49. Manzetti, S. & Mariasiu, F. Electric vehicle battery technologies: From present state to future systems. Renewable and Sustainable Energy Reviews 51, 1004-1012 (2015). 50. Mart nez-Lao, J., Montoya, F. G., Montoya, M. G. & Manzano-Agugliaro, F. Electric vehicles in Spain: An overview of charging systems. Renewable and Sustainable Energy Reviews 77, 970-983 (2017). 51. Mahmoudzadeh Andwari, A., Pesiridis, A., Rajoo, S., Martinez-Botas, R. & Esfahanian, V. A review of Battery Electric Vehicle technology and readiness levels. Renewable and Sustainable Energy Reviews 78, 414-430 (2017).