Computational Materials Education: Kinetics Module Review

Dive into the Kinetics Module of the Summer School for Integrated Computational Materials Education 2018, exploring diffusion, semiconductor processing, computational tools, and more. Understand the driving forces behind diffusion and Fick's laws, with hands-on exercises and analytical solutions to the diffusion equation. Join us at Ann Arbor, MI, from June 4-15, 2018, to enhance your knowledge in this field.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Summer School for Integrated Computational Materials Education 2018 Kinetics Module Review Katsuyo Thornton,1Edwin Garcia,2Larry Aagesen,3 Mark Asta4, Jonathan Guyer5 Department of Materials Science & Engineering, University of Michigan Purdue University Idaho National Laboratory University of California, Berkeley National Institute of Standards and Technology 1. 2. 3. 4. 5.

Purposes of Kinetics Module Develop deeper understanding of diffusive transport through hands-on exercises. Learn how computational tools can be used to determine concentration profiles during diffusion. Demonstrate the technological importance of diffusion through an application to a semiconductor processing problem. Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 4-15, 2018 2

Concepts Illustrated Through Kinetics Module 1. Diffusion Driving Force Fick s Law Mass Conservation 2. Semiconductor Processing 3. Computational Kinetics 4. FiPy Part 1 Part 2 Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 4-15, 2018 3

Driving Force for Diffusion Consider 1D diffusion. The atoms are randomly hopping right and left. Half the atoms are moving toward right, and the other half is moving to left. Below, left side has more atoms than right. Net flux toward the low concentration. Concentration - C x Driving force = High conc. Low conc. x Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 4-15, 2018 4

Ficks First Law The flux is proportional to the driving force. The proportionality constant is the diffusion coefficient. J = D - C = -D C x x high concentration J dc J low concentration dx Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 4-15, 2018 5

Solution to the Diffusion Equation For a fixed concentration on one end of semi- infinite domain, an analytical solution exists. Cs= the surface concentration C0 = initial condition ... Co = C(x, t=0) Cs = C(x=0,t) erf z ( ) = exp -y2 0 Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 4-15, 2018 C(x,t)-C0 CS-C0 x =1- erf 2 Dt z x ( ) z = dy 2 Dt 6

Mass Conservation Mass must be conserved. Difference in flux will lead to change in concentration (accumulation or depletion). Mass conservation equation: C t = - J In 1D: = D 2C C t =- -D C x x x2 Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 4-15, 2018 7

Semiconductor Device Processing oxide passivation metallic conductors active devices (transistors, etc.) silicon chip Manufacture millions of devices simultaneously on a chip Steps in manufacture (simplified) Crystal growth and dicing to chip Photolithography to locate regions for doping Doping to create n-type regions (can in some cases be done during growth) Overlay to create junctions Metallization to interconnect devices Passivation to insulate and isolate devices Higher level packaging to interconnect chips Based on figures from MSE 201 course notes of J. W. Morris, Jr., University of California, Berkeley Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 4-15, 2018

Photolithography Minimum feature size depends on wavelength of light Visible light: ~ 1 m Ultraviolet light: ~ 0.1 m Electrons, x-rays 0.1-1 nm New and exotic methods Must have photoresist suitable to the light Or use light to cut through oxide directly Based on figures from MSE 201 course notes of J. W. Morris, Jr., University of California, Berkeley Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 4-15, 2018

Doping dopant ions dopant distribution Add electrically active species Simple method Coat surface and diffuse Expose surface to a vapor and allow interdiffusion Diffusion field is electrically active More precise: Ion implantation Accelerate ions of the electrically active species toward surface Ions embed to produce doped region Based on figures from MSE 201 course notes of J. W. Morris, Jr., University of California, Berkeley Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 5-16, 2017

Doping: The Chemical Distribution ion implantation laser light dopant distribution laser anneal c diffusion x Initial distribution is inhomogeneous Diffusion produces gradient from surface Ion implantation produces concentration at depth beneath surface Can homogenize by laser annealing Use a laser to melt rapidly, locally Rapid homogenization in melted region Rapid re-solidification since rest of body is heat sink Based on figures from MSE 201 course notes of J. W. Morris, Jr., University of California, Berkeley Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 5-16, 2017

Overlay to Create Junctions n n n n p p Once primary doping is complete Re-coat Re-mask Re-pattern Dope second specie to create desired distribution of junctions Based on figures from MSE 201 course notes of J. W. Morris, Jr., University of California, Berkeley Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 4-15, 2018

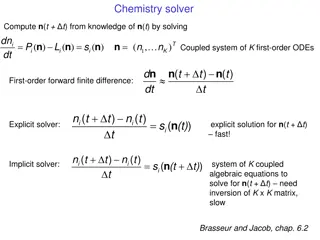

Part 2. Introduction to Computational Kinetics Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 4-15, 2018 13

What is FiPy? Simply put: Is a set of python libraries to solve PDEs In more detail: Provides a numerical framework to solve for the finite-volumes equation The emphasis is on microstructural evolution Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 4-15, 2018 17

FiPy Resources FiPy Manual (tutorials and useful examples) FiPy Reference (what every single command does) Mailing List: fipy@nist.gov You can also email the coauthors: John Guyer: guyer@nist.gov Dan Wheeler: daniel.wheeler@nist.gov FiPy Website http://www.ctcms.nist.gov/fipy/ Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 4-15, 2018 18

A PDE is Solved in Five Steps Variables Definitions Equation(s) Definition(s) Boundary Condition Specification Viewer Creation Problem Solving Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 4-15, 2018 19

Step-By-Step Walk-Though Follows Summer School for Integrated Computational Materials Education Ann Arbor, MI, June 4-15, 2018 20