Corrosion Resistant Chromium-Free Conversion Coatings

In this presentation, potential licensees are introduced to corrosion-resistant chromium-free conversion coatings by Joshua Walles. The focus is on technical opportunities for aluminum conversion coatings, the environmental benefits of hexavalent chromium alternatives, and a potential solution using modified zirconium-based coatings. It also discusses corrosion performance testing on AA6061 aluminum alloy. Discover how these coatings offer a safer and more efficient option for various applications.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Corrosion Resistant Chromium Free Conversion Coatings 28 April 2022 Presented to: Potential Licensees Presented by: Joshua Walles

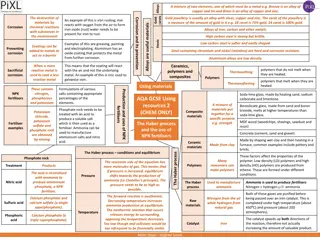

Opportunities Technical Aluminum Conversion Coating Aluminum Anodize Sealing Other Metal Surface Passivation or Post-treatment Environmental REACH compliant Lower ESOH risks 2

Technical Opportunity Aluminum alloys conversion coatings for military use are qualified to MIL-DTL-81706 and its respective QPD and are applied according to MIL- DTL-5541. Chromium free products may be able to protect 6XXX Al in ASTM B117 for 168 hours. Requirements for MIL-DTL-81706/5541 Class 3 testing Expected performance on similar Al alloy series Current products which can protect 2XXX and 7XXX Al in B117 for 336 hours without visible corrosion utilize chromium containing compounds Improved chromium-free products may be able to meet the same minimum performance benchmarks 3

Environmental Opportunity Hexavalent chromium is a known carcinogen and alternatives are needed for use in global markets. Trivalent chromium compounds are being increasingly regulated and some organizations have taken a conservative approach not allowing any chromium containing products. A non-chromium conversion coating, which can offer equal to or better performance than qualified products and be a direct replacement would be ideal. 4

Potential Solution Modified traditional Zirconium-based coatings with inhibitor packages Metal polycarboxylate salts in solution at low solubilities Mechanism may not be to co-deposit onto aluminum substrate like typical corrosion compounds Promising performance Potential to meet hexavalent or trivalent chromium containing products performance Can be applied with similar methods as traditional conversion coatings 5

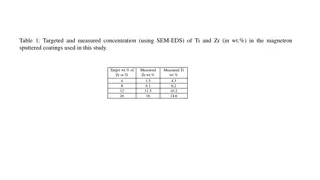

Corrosion Performance AA6061 AA6061- -T6 ASTM B117 Exposure for 8 Days (192 hours) T6 ASTM B117 Exposure for 8 Days (192 hours) COTS Product A COTS Product A NAWCAD NAWCAD Zr Zr Coating Coating COTS Product B COTS Product B Testing on AA6061 is similar to COTS chromium-free products, and meets the corrosion resistance minimum requirements for MIL-DTL-81706 Class 3 (1 weeks). Most mature application. Immersion applied with light agitation/stirring. Expect similar performance on 3XXX and 5XXX series aluminum. 6

Corrosion Performance AA2024 AA2024- -T3 ASTM B117 Exposure for 10 Days (240 hours) T3 ASTM B117 Exposure for 10 Days (240 hours) COTS Product A COTS Product A NAWCAD NAWCAD Zr Corrosion performance of NAWCAD Zr coating on AA2024 is incrementally or much greater than COTS chromium-free products Zr Coating Coating COTS Cr-free products: Coating failure in B117 in 2-4 days NAWCAD Zr coating: Coating failure in B117 in 5-12 days Opportunity to develop the NAWCAD process and increase reliability and/or maximum performance 7

Research Ideas to Advance Technical Readiness Optimized Inhibitor Package Concentrations/Blends Additional Cations and Anions Processing Parameters (to increase consistency) Temperature pH Immersion Time Additional Testing Requirements Paint Adhesion Electrical Contact Resistance 8

Questions? Joshua Walles joshua.g.walles.civ@us.navy.mil 301-342-0453