Cost and Management Accounting

Cost systems offer invaluable insights for management decision-making, enabling efficient resource allocation and operation control. Proper cost management can significantly enhance profitability. This module delves into job costing, highlighting the importance of unit costs for pricing, inventory valuation, and informed management decisions, as well as the various costing systems that companies employ for precise cost tracking. It also discusses job costing statements and their relevance in both manufacturing and service sectors.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

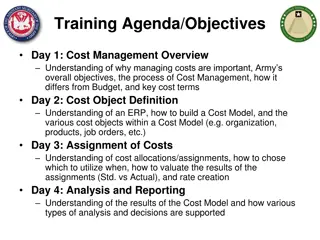

Module 1 Job costing INTRODUCTION Cost systems provide management with useful information to help with decision making. Managers are then able to more efficiently allocate resources and measure and control operations. With good cost management systems in place, a company can become more profitable. www.futuremanagers.com

Module 1 Job costing (continued) UNIT COST Importance of unit cost: To calculate a selling price after mark up. To help management make decisions e.g. stop producing a certain line, initiate new products, accept or reject special orders. To calculate the value of the unsold stock. www.futuremanagers.com

Module 1 Job costing (continued) COSTING SYSTEMS A cost system is a specific method whereby costs for a product or a process are collected, edited and disclosed. Companies use either: A process costing system; A product costing system which is also called job-order costing; or A combination of the two (called operation costing). www.futuremanagers.com

Module 1 Job costing (continued) RECORDING TRANSACTIONS All costs related to a job must be recorded on a job cost sheet, which can be on paper or in electronic form. On the job cost sheet the direct material, labour costs and the overhead costs will be recorded. The job cost sheets may differ from business to business, to suit their own requirements. www.futuremanagers.com

Module 1 Job costing (continued) JOB COSTING STATEMENT A job costing statement is a summary of all the production costs of a job (it can also show an amount for sales and marketing costs.) If the job is completed it includes the selling price and the profit on the job. www.futuremanagers.com

Module 1 Job costing (continued) JOB ORDER COSTING IN SERVICE BUSINESSES Job order costing can be used in both manufacturing and service businesses. In service businesses where jobs differ from one another and there is a need for cost information for separate jobs, several varieties of job order costing are used. These could be in industries such as laundries, tailors, garden services, repairs as well as professional services such as legal, accounting, architectural and consulting services. www.futuremanagers.com

Module 1 Job costing (continued) COMPARING PRODUCT AND PROCESS COSTING SIMILARITIES Both systems use the same ledger accounts for recording transactions regarding manufacturing, material control, production control, finished goods control and so forth. Costs flow through these accounts in the same way in both systems. The purpose of both systems is the same; to apply material, labour and overhead costs to products and to calculate unit cost. www.futuremanagers.com

Module 1 Job costing (continued) COMPARING PRODUCT AND PROCESS COSTING - DIFFERENCES Product costing/ Job order costing Process costing 1. Many different jobs are worked on during the production period, each job with different production requirements 1. A single product is produced either on a continuous basis, or for long periods. All units are identical. Often have joint and by products 2. Cost accumulated by individual job 2. Costs accumulated per department 3. The job cost card is the key document controlling the accumulation of cost by a job 3. The department production report is the key document showing the cost per department. 4. Unit cost is calculated per job on the Job cost card 4. Unit cost is calculated by department or by dividing total cost with total units produced www.futuremanagers.com

Module 2 Contract costing INTRODUCTION Contract costing uses the same principles as job costing but it applies to more substantial projects for example construction of dams, bridges, roads, blocks of flats and so forth. It is a product orientated cost system. A separate contract account is opened and the cost elements will be debited to the applicable contract in order to calculate whether there was a profit. www.futuremanagers.com

Module 2 Contract costing (continued) CONTRACT COST The term contract costing refers to the cost for a particular contract which has accumulated over a period of time. Costs usually fall in three categories: Direct contract cost; Indirect contract cost; and General cost including selling and administration cost. www.futuremanagers.com

Module 2 Contract costing (continued) TYPES OF CONTRACTS There are two basic methods are used for contract accounting: Fixed price contract which is where a contract price is agreed upon beforehand between the contractor and the contractee; and Cost-plus contract which is where the contractor is paid for all his costs plus a fixed extra amount. www.futuremanagers.com

Module 2 Contract costing (continued) CALCULATIONS OF PROFIT At the end of the financial period some contracts will be unfinished. Profits or losses on these unfinished contracts must be estimated. There are methods which can work towards calculating uncompleted projects such as: Completed contract methods the profit can only be calculated when the contract is completed. Percentage of completion method the profit is calculated according to how much work has been completed. www.futuremanagers.com

Module 2 Contract costing (continued) PROVISIONS There is still a possibility of only realising profit (such as in the case of non- payment by a debtor or other unforeseen circumstances) and so a figure can be further qualified by taking into account only the profit realised on the money received. This amount is recorded as a provision in the contract account. www.futuremanagers.com

Module 2 Contract costing (continued) CONCLUSION Contractors estimating contract costs without a complete understanding of the cost components, especially the indirect costs, are unnecessarily increasing the risk and exposure to losses. An understanding of the relationship of indirect costs to the particular contract is very important. www.futuremanagers.com

Module 3 Standard costing INTRODUCTION A standard cost is the predetermined cost of manufacturing a single unit or a specific quantity during a specific period under current or anticipated operating conditions. www.futuremanagers.com

Module 3 Standard costing (continued) THE AIM OF STANDARD COSTING The purpose of standard costing is to furnish relevant information to management for them to make the right decisions. This goes through the following procedure: Establish standards. Determine actual costs. Compare actual with standard costs and calculate the variance. Analyse the variance and introduce measures to correct them. www.futuremanagers.com

Module 3 Standard costing (continued) USE OF STANDARD COSTING Standard cost systems help management with: Planning; Cost control; Establishing budgets; Establishing contract bids and for setting selling prices; Stock valuation; and The keeping of records. www.futuremanagers.com

Module 3 Standard costing (continued) ADVANTAGES OF STANDARD COSTING Actual costs can be measured against the standard costs. Analysing variances will indicate problem areas, which often leads to improvement of operations. The firm becomes more cost conscious. Because it simplifies costing, it reduces clerical work. Workers know what is expected of them. It may stimulate further planning which will lead to greater efficiency. www.futuremanagers.com

Module 3 Standard costing (continued) SETTING OF STANDARDS Under ideal conditions employees accept standards as personal production goals. Once standards are set, a standard cost card should be prepared for each product manufactured or service rendered. This will include: Standard quantities and standard prices of each raw material. Standard labour rate and standard hours. Standard manufacturing overheads. Total standard cost allowed to manufacture a completed product. www.futuremanagers.com

Module 3 Standard costing (continued) VARIANCES The difference between the actual costs for material, labour and overheads and the standard costs is called a variance. This figure can either be favourable (when the actual cost is less than the standard cost) or unfavourable (when the actual cost is more than the standard cost). www.futuremanagers.com

Module 4 Cost control INTRODUCTION These are two different methods used to recover fixed manufacturing costs. Management can decide to use the direct costing or the absorption costing method. The two methods treat fixed manufacturing costs differently. www.futuremanagers.com

Module 4 Cost control (continued) DIRECT COSTING With direct costing, the fixed overheads total are charged against income when the cost is incurred and costs are recovered on the basis of the number of units sold during a period. www.futuremanagers.com

Module 4 Cost control (continued) ABSORPTION COSTING With absorption costing fixed costs are recovered on the basis of the number of units manufactured during the period. A rate for recovery of fixed cost per unit is calculated and written off per unit produced. Absorption costing charges fixed overheads against income when the goods are sold. www.futuremanagers.com

Module 4 Cost control (continued) COMPARISON BETWEEN DIRECT AND ABSORPTION COSTING SYSTEMS Direct costing Absorption costing Charges the total fixed overhead cost against income in the year it was paid. Charges fixed overheads against income when the goods are sold. Matching total fixed cost for a period with revenues (income) of that period. Matching the fixed manufacturing costs with units produced and then only take those costs to the income statement when those goods are sold. Used for internal reporting and analysis. Required for external reporting. Referred to as variable costing or marginal costing, Referred to as conventional costing. www.futuremanagers.com

Module 4 Cost control (continued) BREAK-EVEN ANALYSIS The break-even quantity is the minimum amount of products that must be sold to recover all the costs, without the company making profit or a loss. The formula to calculate Break-even value is: ????????? ????? = ????????? ???????? ??????? ????? ??? ???? www.futuremanagers.com

Module 5 Budgets INTRODUCTION Budgeting shows the route to be taken to achieve goals, and budget control is the comparison of the results achieved with results envisaged. www.futuremanagers.com

Module 5 Budgets (continued) BUDGET CONTROL Budget control is monitoring performance and getting the staff to cooperate in order to achieve those goals and even, if necessary, to take corrective steps before it is too late. www.futuremanagers.com

Module 5 Budgets (continued) TYPES OF BUDGETS OF A MANUFACTURING CONCERN Enterprise uses different budgets to manage the finances such as: Master budget/main budget which coordinates all the other budgets; The sales budget which is the starting point in preparing the master budget; The raw materials budget which plans the required quantity and costs of the materials needed, according to the estimates of the production budget; The labour budget; and The marketing budget. www.futuremanagers.com

Module 5 Budgets (continued) BUDGETED INCOME STATEMENT This statement summarises the budgeted sales, estimated income and expenditure. It projects net income which is the goal towards which all efforts are directed. Management can judge the accuracy of the different budgets. www.futuremanagers.com

Module 5 Budgets (continued) BUDGETED BALANCE SHEET The balance sheet at the end of the budget period reflects all the changes in assets, liabilities and shareholder s interest, resulting from all the budgets submitted by the various departments. It can be seen as control over the accuracy of all the other budgets. www.futuremanagers.com