Crystalline Substance Identification and Size Determination Techniques

Identification of crystalline substances in specimens is achieved through X-ray diffraction analysis, comparing diffraction spectra with known substances. The process involves determining crystalline size using the shape factor and analyzing peak broadening for residual stress effects.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

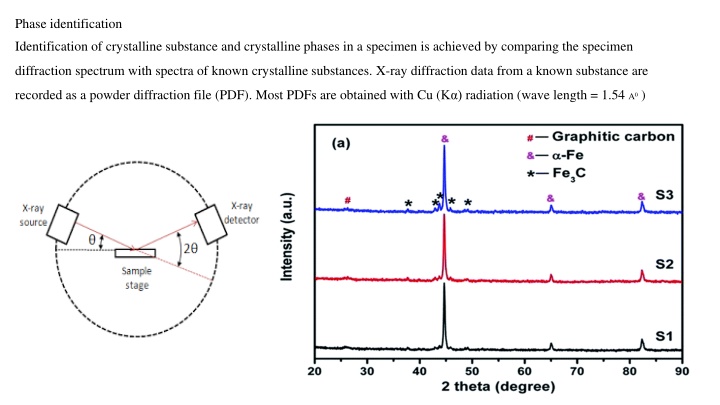

Phase identification Identification of crystalline substance and crystalline phases in a specimen is achieved by comparing the specimen diffraction spectrum with spectra of known crystalline substances. X-ray diffraction data from a known substance are recorded as a powder diffraction file (PDF). Most PDFs are obtained with Cu (K ) radiation (wave length = 1.54 A0)

Crystalline size determination D=K / ( cos ). K= 0.9 ( shape factor), D= crystal size, = fWHM ( full width half max of the peak) in Rad , = bragg's angle Rad = (22 * FWHM) / (7 * 180) = FWHM * 0.01746 Residual stress In real life XRD peaks can be affected by stresses inside the material which are the effect of thermal or mechanical processing, or chemical contamination. Such effects can give rise to peak broadening (especially with grain size) and if residual stresses are present, peak shifting.