Cutting-edge Mechanical Engineering Research Projects

Explore cutting-edge research projects in mechanical engineering focusing on issues such as reliability assessment of composite solder, transient liquid phase bonding, and residual stress prediction in additive manufacturing. Discover innovative methodologies and technologies used in these projects.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

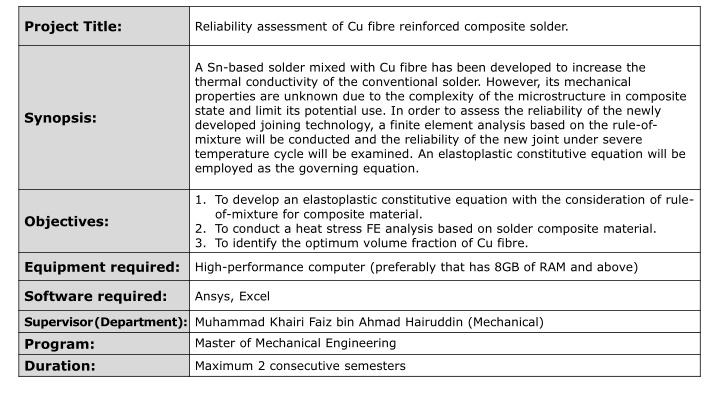

Project Title: Reliability assessment of Cu fibre reinforced composite solder. A Sn-based solder mixed with Cu fibre has been developed to increase the thermal conductivity of the conventional solder. However, its mechanical properties are unknown due to the complexity of the microstructure in composite state and limit its potential use. In order to assess the reliability of the newly developed joining technology, a finite element analysis based on the rule-of- mixture will be conducted and the reliability of the new joint under severe temperature cycle will be examined. An elastoplastic constitutive equation will be employed as the governing equation. Synopsis: 1. To develop an elastoplastic constitutive equation with the consideration of rule- of-mixture for composite material. 2. To conduct a heat stress FE analysis based on solder composite material. 3. To identify the optimum volume fraction of Cu fibre. Objectives: Equipment required: High-performance computer (preferably that has 8GB of RAM and above) Software required: Ansys, Excel Supervisor(Department): Muhammad Khairi Faiz bin Ahmad Hairuddin (Mechanical) Program: Master of Mechanical Engineering Duration: Maximum 2 consecutive semesters

Project Title: Transient liquid phase bonding of Sn-In system A transient liquid phase bonding (TLPB) of In-Sn systems is proposed to achieve a joint with high mechanical properties and high re-melting temperature as compared to its processing temperature for the application in future generation SiC/GaN-based power electronics module. Few thin In and Sn multilayers will be deposited on a Ni-plated Cu and Al substrates by means of physical vapor deposition method. The consumption of In liquid phase into Sn solid phase and the interdiffusion of these two elements is expected to lead to the formation of (Sn)In solid solution that will not only act as strengthening mechanism of the joint, but also allowing the increase of re-melting temperature. The findings of this proposed work will benefit the key players in automotive industry as the power module is a necessary component in the hybrid electric vehicles. Synopsis: 1. To fabricate Cu-Cu using TLPB process of Sn-In system 2. To characterize the microstructure of the as-fabricated Cu-Cu joint 3. To investigate the re-melting temperature of the as-fabricated Cu-Cu joint Objectives: Equipment required: Sputtering machine, reflow oven, grinding & polishing machine, FESEM-EDX, DSC Software required: Excel, Origin Pro Supervisor(Department): Muhammad Khairi Faiz bin Ahmad Hairuddin (Mechanical) Program: Master of Mechanical/Material Engineering Duration: Maximum 2 consecutive semesters

Residual stress prediction of aluminum fabricated by wire-arc additive manufacturing with experimental validation Project Title: Wire-arc additive manufacturing (WAAM) is a type of 3D printing technology that enable rapid manufacturing owing to its fast deposition rate compared to another additive manufacturing method. However, as melting of material is involved during processing, residual stress associated with the thermal gradient inside the object is inevitable. Finite element analysis will be used to predict the residual stress inside an Al fabricated by the WAAM and the accuracy of the simulation will be verified experimentally. Synopsis: 1. To conduct a thermal stress analysis on Al object fabricated by WAAM 2. To predict the residual stress that exist inside the Al sample after fabrication 3. To verify the Objectives: Equipment required: Wire EDM, high-performance computer, strain-gage, data logger Software required: Ansys, Excel Supervisor(Department): Muhammad Khairi Faiz bin Ahmad Hairuddin Program: Master of Mechanical Engineering Duration: Maximum 2 consecutive semesters

Classification of high voltage cable joint defects using support vector machine and noise reduction on partial discharge signals Project Title: In this work, classification of high voltage cable joint defect types using support vector machine and noise reduction techniques on partial discharge signals will be performed. Four cross-linked polyethylene (XLPE) cable joints with artificially created defects will be prepared based on the defects commonly encountered on site. Different noise reduction techniques will be applied to denoise the PD signals. The denoised signals will be used as a feature for classification of defects in cable joints using support vector machine. The classification results will be compared between the proposed method and the existing works to evaluate the performance of the applied techniques. 1. To perform measurement of partial discharge (PD) on artificially-prepared cable joint defects 2. To apply support vector machine and various noise reduction methods on PD signals for classification of XLPE cable joint defects 3. To compare the classification results between the proposed method and the existing works Synopsis: Objectives: Equipment required: Software required: Partial discharge measurement setup, high voltage generation kit, cable joint MATLAB, partial discharge analysis software Supervisor(Department): Assoc. Prof. Ir. Dr. Hazlee Azil Illias (Electrical) Program: Master of Power System Engineering / Master of Engineering (Power System) Duration: Maximum 2 consecutive semesters