Defining Project Management: Five Phases of Project Life Cycle

Project management involves initiating, planning, executing, controlling, and closing work to achieve specific goals within a specified time. The project life cycle consists of planning, executing, controlling, and closing phases. Defining project scope, managing people, and the importance of planning are key aspects highlighted in the content.

Uploaded on Mar 16, 2025 | 2 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

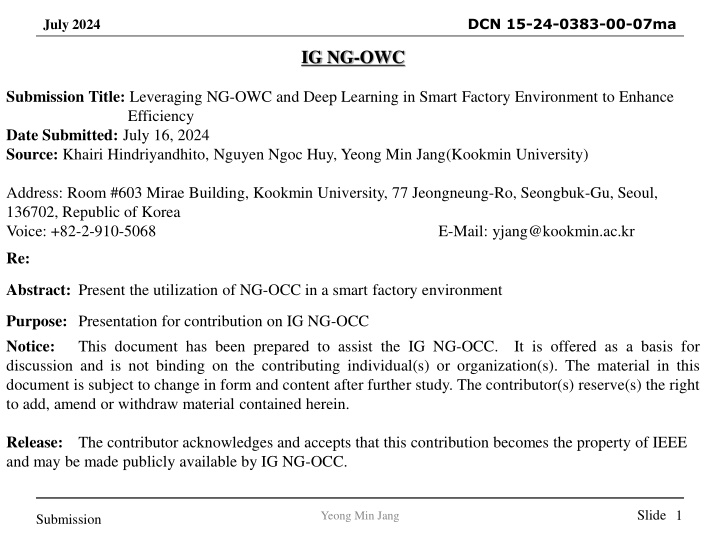

DCN 15-24-0383-00-07ma July 2024 IG NG-OWC Submission Title: Leveraging NG-OWC and Deep Learning in Smart Factory Environment to Enhance Efficiency Date Submitted: July 16, 2024 Source: Khairi Hindriyandhito, Nguyen Ngoc Huy, Yeong Min Jang(Kookmin University) Address: Room #603 Mirae Building, Kookmin University, 77 Jeongneung-Ro, Seongbuk-Gu, Seoul, 136702, Republic of Korea Voice: +82-2-910-5068 E-Mail: yjang@kookmin.ac.kr Re: Abstract: Present the utilization of NG-OCC in a smart factory environment Purpose: Presentation for contribution on IG NG-OCC Notice: This document has been prepared to assist the IG NG-OCC. It is offered as a basis for discussion and is not binding on the contributing individual(s) or organization(s). The material in this document is subject to change in form and content after further study. The contributor(s) reserve(s) the right to add, amend or withdraw material contained herein. Release: The contributor acknowledges and accepts that this contribution becomes the property of IEEE and may be made publicly available by IG NG-OCC. Slide 1 Yeong Min Jang Submission

DCN 15-24-0383-00-07ma July 2024 Leveraging NG-OWC and Deep Learning in Smart Factory Environment to Enhance Efficiency July 16, 2024 Slide 2 Yeong Min Jang Submission

DCN 15-24-0383-00-07ma July 2024 Contents Background NG-OWC for Smart Factory NG-OWC and Deep Learning for Smart Factory Conclusion Slide 3 Yeong Min Jang Submission

DCN 15-24-0383-00-07ma July 2024 Background Optical Camera Communication (OCC) is a cutting-edge technology that enables data transmission through light signals captured by camera sensors. Recent advancements have significantly improved the data rate, reliability, and integration capabilities of OCC, making it a viable communication protocol for smart factory environments. By leveraging existing CCTV infrastructure, OCC can transform surveillance cameras into multi-purpose devices, simultaneously supporting security monitoring and data communication without the need for additional hardware. Implementing a unified system that combines OCC and deep learning transforms CCTV cameras into multifunctional devices. This system can simultaneously perform data reception and advanced surveillance tasks, streamlining the communication infrastructure within a smart factory. Slide 4 Yeong Min Jang Submission

DCN 15-24-0383-00-07ma July 2024 NG-OWC for Smart Factory From the sensor employed in an industrial room, there would be an OCC transmitter using LED array. The receiver is the existing CCTV that being used for room monitoring. Eliminating the needs for another communication protocol and hardware between sensors and system. Slide 5 Yeong Min Jang Submission

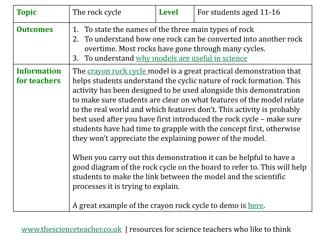

DCN 15-24-0383-00-07ma July 2024 NG-OWC and Deep Learning for Smart Factory Sensors CCTV OCC Communication Multi-Object Tracking Early Fire Detection Temperature Humidity Anomaly Detection Intruder Detection PM 2.5 <OCC and Deep Learning Integration for Smart Factory Environment> The sensors would be integrated with an OCC transmitter (LED array) The LED array would then be captured by CCTV alongside with the surrounding image From the image received then it would be processed with multi-object tracking to detect multiple object The system then could detect early fire sign, intruder, or anomalies in the image by leveraging deep learning Slide 6 Yeong Min Jang Submission

DCN 15-24-0383-00-07ma July 2024 Conclusion Leveraging next-generation Optical Camera Communication (OCC) and deep learning in smart factories utilizes existing CCTV infrastructure for dual-purpose communication and surveillance, reducing additional hardware needs Integrating deep learning algorithms with CCTV systems enhances safety and operational efficiency through robust, automated fire and intruder detection. This unified system simplifies communication protocols and device maintenance, leading to cost savings and enhanced efficiency in smart factory. Slide 7 Yeong Min Jang Submission

DCN 15-24-0383-00-07ma July 2024 Reference 1. Van Hoa, N., Nguyen, H., Nguyen, C. H., & Jang, Y. M. (2020, October). Occ technology-based developing iot network. In 2020 International Conference on Information and Communication Technology Convergence (ICTC) (pp. 670- 673). IEEE. 2. Ahmed, M. F., Hasan, M. K., Chowdhury, M. Z., Hoan, N. C., & Jang, Y. M. (2021). Continuous status monitoring of industrial valve using OCC-enabled wireless sensor network. IEEE Transactions on Instrumentation and Measurement, 71, 1-10. 3. Herfandi, H., Sitanggang, O. S., Nasution, M. R. A., Nguyen, H., & Jang, Y. M. (2024). Real-Time Patient Indoor Health Monitoring and Location Tracking with Optical Camera Communications on the Internet of Medical Things. Applied Sciences, 14(3), 1153. Slide 8 Yeong Min Jang Submission