Dehydration as a Food Preservation Method Overview

Explore the process of dehydration as a food preservation method, including the transfer of water and heat, preservation effects, water activity levels for various dried foods, differences between concentration and dehydration, changes during dehydration like shrinkage and case hardening. Understand how dehydration helps in extending the shelf life of food products.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

DEHYDRATION AS A FOOD PRESERVATION METHOD Jai Singh Deptt. Of Food Technology CBL Govt. Polytechnic, Bhiwani

THE PROCESS OF DEHYDRATION During dehydration; 1. Water- transfer from the food into the dehydrating environment 2. Heat- transferred to the food ( promoting water removal from the food)

PRESERVATION EFFECT This is an exception of food pathogens DH foods have lower water activity (aw0.2-0.6 -> Not enough free water for : Microbial Growth ( needs aw> 0.93) Staphylococcus aureus (aw> 0.85) PATHOGEN! Mold ( need aw >0.6) Enzymatic reactions Chemical reactions ( eg) Mailllard browning) at aw>0.3 BUT Microorganisms are not killed MO will resume growth after food is rehydrated

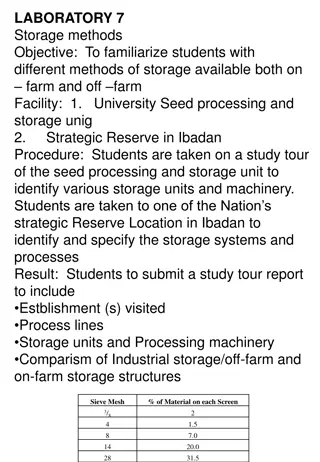

AWFOR SOME DRIED FOODS Product Skim milk powder Dehydrated soups noodles Fruit: berries, apples, apricots, raisins ( grapes) aW 0.03 0.5 0.6 Fruit juice concentrates, condensed milk 0.8

DIFFERENCES IN CONCENTRATION AND DEHYDRATION Both involve physical removal of water from food Dehydration : removal of as much water from the food as possible Imparts a long storage life Concentration: some of the water is removed from the food Concentrates the food constituents Foods are not fully shelf stable . Other forms of processing are needed (can/freeze) Fruit juices, canned soup, jams, evaporated milk, condensed milk, maple syrup

CHANGES DURING DEHYDRATION Cell/ tissue shrinkage Case hardening Chemical changes

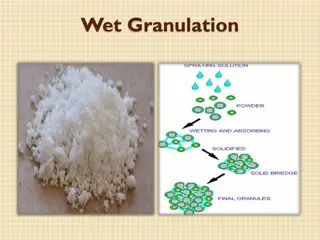

Shrinkage Water migrates- interior of the food surface Evaporates by the drying medium Water carries with it water soluble substances dissolved in it Shrinkage

CHANGES DURING DEHYDRATION Case hardening Rapid drying- compounds (such as sugar) form a hard, impermeable case around the food piece Can slow down the dehydration Common in high sugar products Tropical and temperate fruit products

CHANGES DURING DEHYDRATION Chemical changes Browning and flavor changes due to reactions Maillard browning = from increased solution concentration Denaturation of proteins, aggregation of polysaccharides Loss of water soluble binding capacity Loss of water soluble components or Concentration on the surface of the food ( case hardening) Loss of volatiles ( especially flavor compounds) NOTE: Not all dehydrated foods show these changes it depends on the method of drying

GRAPES VS RAISINS.. Look at differences in Appearance Texture Flavor ( aroma and taste) 4.5 # of grapes = 1 lb raisins Which is sweeter? Which is shelf stable at room temperature? Why?

FACTORS AFFECTING DEHYDRATION Surface area Smaller food piece, more rapid the rate of moisture loss Temperature Increase in temperature will increase the dehydration rate Air velocity Maximize velocity of heated air moving around the food particles Humidity of drying air The drier the air, the moisture it can absorb % RH (relative humidity) of the drying air determines the final moisture content of food

FACTORS AFFECTING DEHYDRATION Atmospheric pressure and vacuum Water boils at 100oC ( at a pressure of 1 atm= 760Hg) At lower pressure the boiling temperature will decrease Eg. Under vacuum, water will boil at 32oC Important for heat sensitive food products ONLY USED FOR FREEZE DRYING

DRYING METHODS Sun dry Spray drying Air ( Tray) Drying Drum Drying Freeze drying

SUN DRYING Dry, warm climates Slow drying method ( several days) Fruits, vegetables, fish Inexpensive Invasion by insects, birds, rodents, microorganisms

SPRAY DRYING Small droplets; rapid dehydration Liquid food Hot dry air 347oF Exit moist air Food must be liquid Air cyclone seperator Fastest method to dehydrate Height of chamber is based on time needed to dehydrate given food Dry food collection Used for milk, eggs, protein powders, Flavorings, and coffee

TRAY (AIR) DRYING Trays or racks Heated air ( 140-176oF) at set velocity and with a low %Relative humidity Poor/ moderate rehydration properties ( case hardening) Food shrinkage, dense product, shape not held Quick, inexpensive Small scale 10-20 hrs needed Ex) Pasta, vegetables, fruit, herbs and spices

DRUM DRYING Food is more likely to be flakey Ex) purees, pastas and mashed foods Mashed potatoes, tomato pastes Size of drum and speed of rotation is determined by drying time needed 248oF 248oF

FREEZE DRYING (LYOPHILIZATION) Food must be in frozen state Vacuum chamber Heat from radiant heaters- energy Water will sublime: Water ( solid) water (vapor) No transition through a liquid state (no evaporation)

FREEZE DRYING (CHARACTERISTICS) Voids from ice crystals when water sublimes ( act as channels) Excellent rehydration No translocation of water soluble constituents to the surface Shape of food is retained (no shrinkage) food closely resembles starting material very expensive used for high value foods Instant soups, high quality coffee, vegetables, military rations, space food

PACKAGING REQUIREMENTS FOR DEHYDRATED FOODS Protect against moisture absorption Dehydrated foods- hygroscopic Prevent transmission of water vapor Physical protection Prevents crushing Freeze dried foods- porous structures with spaces; easily crushed Protection from oxygen and light photo- oxidation