DENSO Robot Simulation Using WinCap lll Software - Final Project Details

Explore how DENSO's WinCap lll software facilitates robot simulation and programming for projects like cup stacking. Understand the process of importing CAD models, programming commands, user interface, and the benefits of using CAD designs. Gain insights into lessons learned and the versatility of the programming language in creating simulations.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

DENSO Robot Simulation with WinCAP lll Software CATIA Final Project Reb Revels & Smirthya Somaskantha Iyer

What is WinCap lll Software? DENSO has its own software, WinCap lll, which will allow the user to simulate or program the action of the robot. DENSO's WINCAPS III offline programming software enables users to conveniently program a robot from a remote PC without operating the robot

Project Description Creating a simulation with the WinCap lll software. The DENSO robot will perform a cup stacking process. Import external CAD models to the simulation.

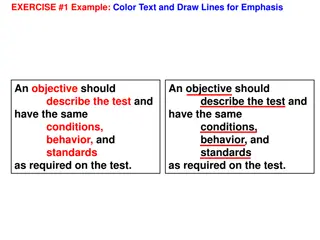

Programming The code is pretty simple All commands have to relate to a move of the machine. the approach and depart command give the arm a specific way to move. You can define speed and delay time for certain actions

CAD Designed Cup We learned to import 3D cad designs using solidworks. This not only gave us the ability to be more accurate with our simulation but also saved time from constructing fixtures in the program with built in shapes.

Lesson Learned CAD drawings can be imported in standard VRML and DirectX formats, and variables can be easily entered or changed. A 3-D simulation feature allows layout of automation workcells in a virtual environment. Users can verify reach, determine obstacle clearances, detect collisions, troubleshoot and debug programs, and determine cycle time. We leant how to program the robot to do what we want it to do. The programming language is unique but it is very basic and direct.