Development of Aviation Biofuel from Pyrolysis Using Neural Networks

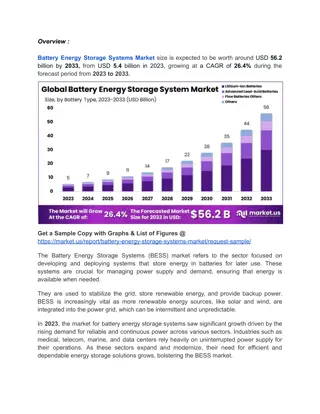

Explore the model development of aviation biofuel production from pyrolysis using artificial neural networks at the Thermal & Fluids Analysis Workshop. The study focuses on predicting product content under various reactor conditions, emphasizing the advantages of hydropyrolysis of biomass for biofuel production.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

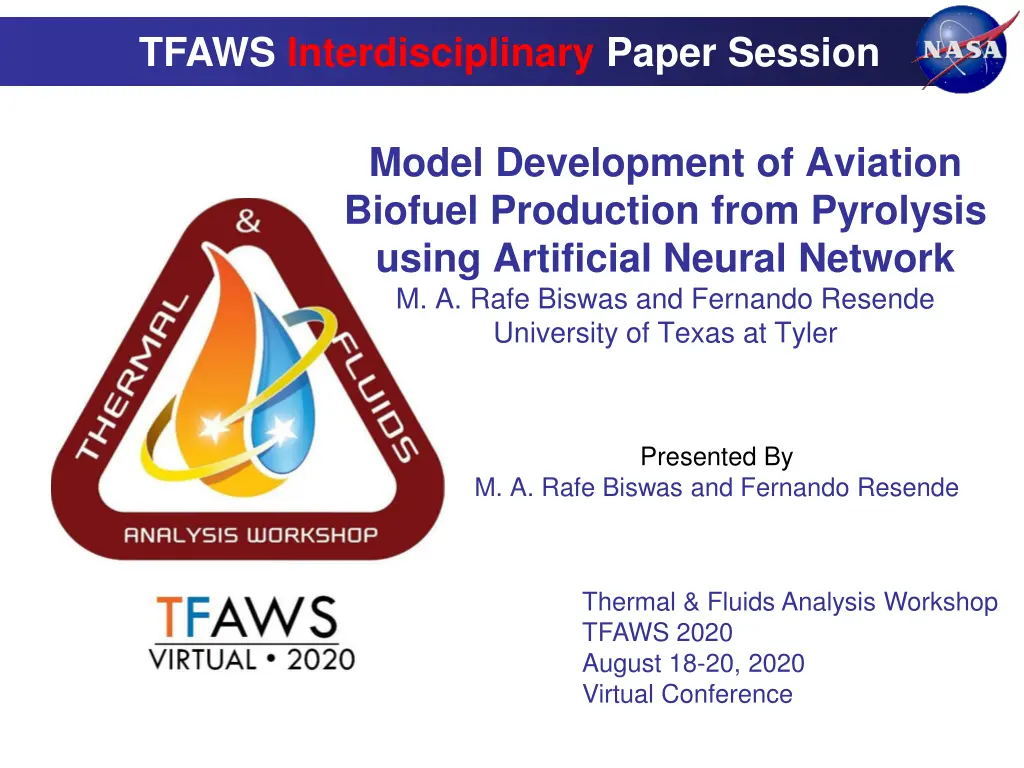

TFAWS Interdisciplinary Paper Session Model Development of Aviation Biofuel Production from Pyrolysis using Artificial Neural Network M. A. Rafe Biswas and Fernando Resende University of Texas at Tyler Presented By M. A. Rafe Biswas and Fernando Resende Thermal & Fluids Analysis Workshop TFAWS 2020 August 18-20, 2020 Virtual Conference

Overview Background Motivation Modeling Objective Experimental Setup and Data Modeling Approach - Artificial Neural Network Statistical Model Verification Results Conclusions TFAWS 2020 August 18-20, 2020 2

Background Lignocellulosic Biomass Renewable Carbon neutral Large availability Eliminates residues CO2 GreenWood Resources' select poplar varieties in Oregon grow very rapidly, one reason they are considered a promising feedstock for biofuels. Switchgrass Hybrid Poplar Distiller s dried grains sith solubles Corn Stover TFAWS 2020 August 18-20, 2020 3

Background Typical Composition of Aviation Fuels - Hydrocarbons Fractions n-paraffins Iso-paraffins Olefins Aromatics Naphthenes Wt. % 28.1-37.5 38.8-81.2 0.3-6.6 2.6-14.4 Paraffins 4.9 15.1 File:Toluol.svg File:Para-Xylol - para-xylene.svg Naphthenes Aromatics Anamaria P.P. Pires, Yinglei Han; John Kramlich; Manuel Garcia-Perez, Bioresources, 13 (2), 2632-2657. TFAWS 2020 August 18-20, 2020 4

Background Hydropyrolysis of Biomass Biomass + heat + H2 + catalyst Expected Advantages: Variety of products High liquid yields Moderate H2 pressure required Little catalyst coking Products: File:Toluol.svg File:Para-Xylol - para-xylene.svg P-xylene Cyclohexane Alkanes benzene toluene TFAWS 2020 August 18-20, 2020 5

Motivation To predict content of products of hydropyrolysis under different operating conditions of the reactor. Artificial neural networks (ANN) modeling approach can: handle complex characteristics of input and output variables including pressure and temperature converge to a solution quickly with low error account for nonlinear behavior TFAWS 2020 August 18-20, 2020 6

Objective Employ ANN Feedforward network with Levenberg-Marquardt (LM) algorithm for model development Compare and assess the steady state empirical models for best fit under known operating conditions Liquid product content model Hydrocarbon product content in liquid model TFAWS 2020 August 18-20, 2020 7

Experimental setup Variables Units Operating range Inputs Hydrogen Composition % 0 or 100 oC Temperature 350-550 Pressure Pa (abs) 1 to 35 x 105 Nickel catalyst loading wt% 0-1.5 Outputs Liquid Content Hydrocarbon Content in Liquid wt% 0-100 Carbon wt% 0-100 TFAWS 2020 August 18-20, 2020 8

Experimental setup High-Pressure fluidized bed reactor TFAWS 2020 August 18-20, 2020 9

Sample Experimental Data Effect of adding nickel TFAWS 2020 August 18-20, 2020 10

Modeling approach Artificial Neural Network layout Output Layer Input Layer Hidden Layer O I ?? ?? f( ) f( ) bi bo 1 1 WI input weight matrix WO output layer weight matrix bi input bias weight vector bo output bias weight vector ?( ) activation function I & O input and output data TFAWS 2020 August 18-20, 2020 11

Modeling approach Function fitting neural network Two-layer feed-forward network Levenberg-Marquardt (LM) backpropagation algorithm 4 Input variables 1-2 Output neuron(s) Varied # of Hidden layer neurons TFAWS 2020 August 18-20, 2020 12 Reference: Mathworks Inc.

Statistical Analysis Mean Squared Error - closeness of fit (converge to 0) 1 ? ? ?2 MSE = Coefficient of Determination strength of fit (closer to 1) ?2= ??? ?,Y 2 SSE = 1 ? ?2 ? mean experimental value SSE sum of squared error Y experimental data Z model results n number of data points TFAWS 2020 August 18-20, 2020 13

Results of Liquid Content Model R2 # of Hidden Neurons MSE 1 5 6 7 8 9 10 15 0.74521 0.63047 0.86702 0.85651 0.87043 0.62623 0.87203 0.87257 20.962 50.057 11.004 14.556 10.762 28.789 10.661 10.624 TFAWS 2020 August 18-20, 2020 14

Results of Liquid Content Model TFAWS 2020 August 18-20, 2020 15

Results of Liquid Content Model TFAWS 2020 August 18-20, 2020 16

Results of Hydrocarbon Content Model # of Hidden Neurons R2 MSE 1 3 0.88332 0.93371 3.5014 2.034 6 0.91463 2.5788 7 8 9 10 15 0.93605 0.93863 0.8107 0.93534 0.91622 2.0263 1.9501 5.7278 2.0631 3.6999 TFAWS 2020 August 18-20, 2020 17

Results of Hydrocarbon Content Model TFAWS 2020 August 18-20, 2020 18

Results of Hydrocarbon Content Model TFAWS 2020 August 18-20, 2020 19

Conclusions Most models showed relatively good fit to the experimental data with varying hidden neurons (3-10). Hydrocarbon Content in Liquid models with MSE < 6 and 0.95 > R2 > 0.8 Liquid content in Hydropyrolysis product models with MSE < 15 and 0.86 > R2 > 0.75 Prediction for Hydrocarbon Content in Liquid is better than the Liquid content model compared to the respective experimental data Selected models can be employed in predicting production of liquid and hydrocarbon content from hydropyrolysis for design of experiment TFAWS 2020 August 18-20, 2020 20

Acknowledgements Graduate student: Devin Chandler Funding and Support: TFAWS 2020 August 18-20, 2020 21

References Anamaria P.P. Pires, Yinglei Han; John Kramlich; Chemical Composition and Fuel Properties of Alternative Jet Fuels, Manuel Garcia-Perez, Bioresources, 13 (2), 2632-2657 Chandler, D.S.; Resende, F.L.P.; Comparison between catalytic fast pyrolysis and cataltic fast hydropyrolysis for the production of liquid fuels in a fluidized bed reactor, Energy & Fuels, 33, 4, 3199-3209, 2019. Chandler, D.S., Seufitelli, G.V.S.; Resende, F.L.P.; A Novel Catalytic Route for Production of Alkanes from Hydropyrolysis of Biomass, submitted to Energy & Fuels. Biswas, M. A. Rafe, Mwara, K. N. " Thermal Fluid Model Development of Steam Methane Reformer using Artificial Neural Network." Interdisciplinary Paper Session, TFAWS (2018). TFAWS 2020 August 18-20, 2020 22

Back up slides TFAWS 2020 August 18-20, 2020 24

Results of Liquid Content Model TFAWS 2020 August 18-20, 2020 25

Results of Hydrocarbon Content Model TFAWS 2020 August 18-20, 2020 26