DOE Accelerator Safety Revision and Lessons Learned

This content discusses the revision and implementation of DOE Order 420.2D for the safety of accelerators. It includes insights from assist visits, lessons learned, challenges identified, and future steps to ensure compliance with the new requirements. Contractor involvement, implementation plans, and feedback from Accelerator Safety Workshops are highlighted to enhance understanding and readiness for the transition to the revised order.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

DOE Order 420.2D, Safety of Accelerators Revision, Implementation and Assist Visit Lessons Learned DOE Accelerator Safety Workshop Oct 8, 2024 Michael Epps Sr. Accelerator Safety Program Manager DOE Office of Safety and Security, SC-OSS

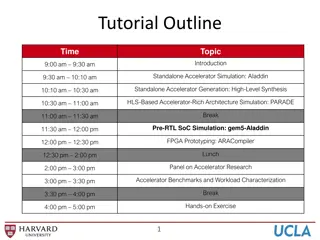

Outline 420.2D Revision and Implementation Assist Visit Purpose/Goals Lessons Learned Next Steps 2

Revision and Implementation DOE O 420.2D, Safety of Accelerators approved Sept 9, 2022. Last revision in 2011. Changes to Applicability, Exemptions, Equivalencies, Requirements, Roles and Responsibilities, and Definitions. Revised under the DOE Departmental Directives Program. Provides requirements and defines the process to create or revise directives. Integrated Project Team plus contractor sub-team provided collaborative input. The Office of Science (SC) recognized the need for additional support and guidance to ensure successful compliance with the new requirements. High level implementation plan was developed with stakeholder input. SC led a series of site assist visits designed to support federal and lab staff. 3

Assist Visit Purpose/Goals Engage with each site at the field level. Direct observation of ongoing implementation efforts. Discussions include all aspects of the accelerator safety program (ASP) including management, operation, and oversight Identify challenges and areas of concern including the ASP interface with institutional programs (CAS, ISM, Rad Protection, etc.). Share ideas with Accelerator Safety colleagues. Provide guidance about applicability, interpretations, and equivalencies. Communicate expectations. Identify opportunities for improvement and share lessons learned. 4

Lessons Learned Expanded contractor involvement in the Order revision process provided valuable insight and helped initiate preparations for the transition to 420.2D. Contractor Support Sub-Team served as a contractor community soundboard for the IPT. Developing an implementation plan with milestones allowed each lab to develop a compliance plan of action aligned with Site Office and HQ expectations. Assist visits provided an opportunity to receive peer to peer feedback and make programmatic adjustments prior to an external review. The 2020 and 2021 Accelerator Safety Workshops provided a valuable platform for open discussion with staff level individuals who were responsible for implementing the new requirements at their respective sites. Managing previously exempted devices under 420.2D has not created an undue burden on the accelerator safety program. Questions remain about Accelerator Safety Order (ASO) requirements for 14.1 MeV neutron generators. 5

Lessons Learned Projects involving accelerators must include adequate time in the project schedule for site office review, feedback, and approval of required processes and procedures related to the ASO. The ARR process continues to be a critical tool to maintain high standards across the accelerator community and support a self-policing approach. DOE must maintain an active Community of Practice (CoP) that supports a rigorous ARR process. Cannot be lax in our application or documentation. Isolation from the CoP can lead to inconsistent interpretation and application of ASO requirements. Labs and site offices should consider establishing an institutional ARR process that provides the minimum requirements necessary to meet expectations (e.g., lines of inquiry, team membership, pre/post-start findings, etc.). 6

Lessons Learned HQ must remain engaged post implementation to ensure expectations remain clear and consistent. (interpretation matches intent). CAS components for accelerator safety must align with DOE expectations. Lab management visibility and ownership must be clear and transparent. Large multiprogram Labs may benefit from the establishment of a process to consolidate and communicate best practices, promote consistency, and enhance organization learning/continuous improvement where applicable. General upkeep on aging infrastructure is commendable however, component labeling varies widely across SC. Use of an appropriate crosswalk to identify institutional programs used to satisfy ASO requirements provided clarity to the assist team. Recommend for future reviews. The accelerator safety guide must be updated to reflect new requirements and incorporate acquired operational experience. 7

Next Steps Continue to provide programmatic support across the complex to ensure successful operations under 420.2D. Complete requested LANL assist visit 1st Quarter FY25. Update accompanying accelerator safety guidance and support documents. Accelerator Safety Order Implementation Guide Accelerator Safety Oversight Federal Qualification Standard Office of Science Management System (SCMS), Accelerator safety procedures DOE-STD-6004 - Clearance, and Release of Personal Property from Accelerators 8

Noted Best Practices PPPL Uses an Institutional Engineering Configuration Management Program. A graded approach has been implemented via the PPPL QA Program Description. Using ANSI/ASME A13.1 White on Purple labeling for all credited control devices and systems is commendable. Labeling was clear and easy to identify in the field. Each configuration managed component had a design drawing number on the sticker. ORNL Implemented a comprehensive configuration management policy/process (Graded based on elements of DOE-STD-1073) that extends beyond Accelerator Safety at SNS. ANL Use of a carefully constructed component database facilitates an excellent configuration management program to support the APS-U project. LBNL Site office uses an official process to review, record, and approve accelerator safety document submissions. 10