Eddy Current Effects in the 2nd Harmonic Booster Cavity Study

Explore the impact of eddy current effects in the tuner of the 2nd harmonic booster cavity through 3D modeling. Delve into the main findings of the study and the implications for cavity performance.

Uploaded on Mar 07, 2025 | 2 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Eddy Current Effects in the Tuner of Eddy Current Effects in the Tuner of the 2 the 2- -nd Harmonic Booster Cavity nd Harmonic Booster Cavity Main results of the tuner study by 3D modeling 1/5/2017 2-nd harmonic cavity meeting 1

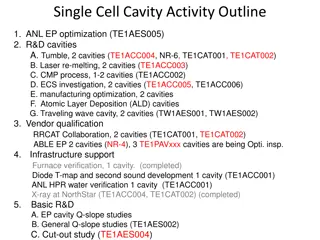

2D analysis results refresher 2D analysis results refresher Current Ramp (simplified) Geometry N = 50 d(Iw)/dt|max = 3000 A/ms d(Iw)/dt|set = 1000 A/ms I_start 170 A Shell thickness Copper coating Eddy current at the start corresponds to ~10% of the excitation current t = 3 mm 25 m Additional thermal loss is ~1200 W, that is ~40% of the loss in the garnet. 1/5/2017 2-nd harmonic cavity meeting 2

3D study setting 3D study setting From the point of view of keeping the anomalous RF power loss in the garnet material of the tuner under control, the most challenging part of the accelerating cycle is injection, where the magnetic field is the closest to the gyromagnetic resonance condition. Only this part of the cycle was studied. The current rise rate at this stage reaches its maximum value for the active part of the cycle, so results will apply to the whole cycle. At the injection, the current rise is described by the following expression (N = 50): I(t) [A] = 167.855 + 3.36 t2 [ms] Example of the bias current shape is a pulsed power supply is used (not an wide-band power source of an amplifier type) 1/5/2017 2-nd harmonic cavity meeting 3

Current rise setting Current rise during the setting part of the current pulse makes its impact of the magnetic field in the tuner due to eddy currents it generated in the shell. The initial current rise rate of the power supply (from the beginning of the cycle at t = -10 s in the figure to the beginning of the injection period at t = 0) must be chosen to make this impact tolerable. The maximum current rise rate d(Iw)/dt = 1000 A/ms. 2D study was made with d(Iw)/dt|set = 1000 A/ms, but during the active part of the pulse d(Iw)/dt|max = 3000 A/ms. The initial proposal for the power supply by Matt Kufer assumes the setting current rose rate d(Iw)/dt = 4500 A/ms Starting point: d(Iw)/dt|set = 2200 A/ms 1/5/2017 2-nd harmonic cavity meeting 4

Modeling time line Modeling time line 1. Transparent (high resistance material) shield 2. Stainless steel cylindrical shield (t = 3 mm) (for comparison with the 2D case) 3. Shield made of four insulated sectors 4. Partially slotted shield 5. Effect of the current rise rate 6. Impact of copper coating 7. Expanded slots 8. Ultimate slots Sampling points: Point #1 Point #2 Point #3 Point #4 Point #5 Point #6 Point #7 Point #8 Point #9 Point #10 t_start = 6 ms Z = 8 mm, Z = 8 mm, Z = 120 mm, Z = 120 mm, Z = 8 mm Z = 8 mm Z = 8 mm Z = 120 mm Z = 120 mm Z = 120 mm R = 110 mm R = 165 mm R = 110 mm R = 165 mm R = 110 mm @ 45 R = 140 mm @ 45 R = 165 mm @ 45 R = 110 mm @ 45 R = 140 mm @ 45 R = 165 mm @ 45 1/5/2017 2-nd harmonic cavity meeting 5

Transfer Functions at the Sampling Points Transfer Functions at the Sampling Points Transparent Shield Axially Symmetric Stainless Steel Four Segments 1/5/2017 2-nd harmonic cavity meeting 6

Transfer Functions at the Sampling Points Transfer Functions at the Sampling Points Four segments; partial slots The slots do to cut the flanges 1/5/2017 2-nd harmonic cavity meeting 7

Slower Current Rise Slower Current Rise d(Iw)/dt|max = 1000 A/ms t_start = 11 ms 3 mm, no coating 3 mm, Cu coating Ideal case 1/5/2017 2-nd harmonic cavity meeting 8

More aggressive slotting Slots cut the flanges in a way that keeps the current cooling pipe configuration Partial slots, slow current rise, Cu coating (from p. 8) Extended slots Although there is some effect of restricting the eddy currents this way, it is not strong. Practically, no big difference exists between this case with the extended slots and the case with limited cutting just on the cylindrical surface. 1/5/2017 2-nd harmonic cavity meeting 9

Ultimate Slotting Ultimate Slotting The cut at 45 degrees goes through all flanges. This means that two cooling circuits will be used on one quarter, not one. This cut also extended to the pipe to limit this way of the eddy current closing. 1/5/2017 2-nd harmonic cavity meeting 10

Current rise rate effect for Current rise rate effect for the eight segments case the eight segments case Faster: d(Iw)/dt = 2200 A/ms Fastest: d(Iw)/dt = 4000 A/ms Slow: d(Iw)/dt = 1000 A/ms Injection starts at 11 ms Injection starts at 6 ms Injection starts at 3.75 ms 1/5/2017 2-nd harmonic cavity meeting 11

Azimuthal dependence of Azimuthal dependence of the transfer function the transfer function Four segments design Simple slots Four segments design No slots Eight segments design The graphs are along the edges of the garnet s the first and the last blocks at the inner and the outer radii. They do not go through the points #1 to #10, so the data is bit different. The setting current rise rate if 2.2 kA/s for all the cases. 1/5/2017 2-nd harmonic cavity meeting 12

Relative case Relative case- -to to- -case change of the transfer function the transfer function case change of Z = 0; R_in; 0 Z = 0; R_out; 0 Z = 120 mm; R_in; 0 #2 0 -7.71 1.12 0.58 0.08 0.44 -0.01 -0.21 -0.38 -0.01 -0.35 -0.28 Z = 120 mm; R_out; 0 Z = 0; R_in; 45 #4 0 -9.79 -6.08 -6.00 -5.62 -5.59 -6.28 -5.91 -5.68 -5.89 -5.84 -5.59 Z = 0; R_out; 45 Z = 120 mm; R_in; 45 Z = 120 mm; R_out; 45 #8 0 -11.56 -2.01 -1.37 -0.79 -0.83 -2.07 -1.61 -1.28 -2.07 -1.92 -1.62 Option 0 1 2 3 4 5 6 7 8 9 10 11 t_inj (ms) 6 6 6 6 11 11 3.75 6 11 3.75 6 11 #1 0 #3 0 #5 0 #7 0 #10 0 -9.79 -0.69 -5.17 -4.67 -4.68 -5.83 -4.99 -4.48 -2.07 -2.03 -1.78 -20.10 1.39 0.85 0.25 0.64 0.17 -0.09 -0.27 0.20 -0.11 -0.02 -11.56 -3.99 -3.76 -3.18 -3.23 -4.25 -3.70 -3.31 -3.50 -3.35 -3.05 -20.10 -2.59 -2.56 -0.70 -1.19 -4.31 -1.43 -0.06 0.81 0.53 0.63 -7.71 -2.40 -9.16 -7.27 -7.78 -3.94 -1.36 -0.09 0.95 0.63 0.72 Option 0 1 2 3 4 5 6 7 8 9 10 11 Axial symm; transparent shell Axial symm; 3 mm; 2.2 kA/ms Four segm.; no cuts; 3 mm; 2.2 kA/ms Four segm.; simple cuts; 3 mm; 2.2 kA/ms Four segm.; simple cuts; 3 mm; 1 kA/ms Four segm.; simple cuts; 4 mm; 1 kA/ms Four segm.; extended cuts; 4 mm; 4 kA/ms Four segm.; extended cuts; 4 mm; 2.2 kA/ms Four segm.; extended cuts; 4 mm; 1 kA/ms Eight segm.; 4 mm; 4 kA/ms Eight segm.; 4 mm; 2.2 kA/ms Eight segm.; 4 mm; 1 kA/ms Description Sampling points: Point #1 Point #2 Point #3 Point #4 Point #5 Point #6 Point #7 Point #8 Point #9 Point #10 Z = 8 mm, Z = 8 mm, Z = 120 mm, Z = 120 mm, Z = 8 mm Z = 8 mm Z = 8 mm Z = 120 mm R = 110 mm @ 45 Z = 120 mm R = 140 mm @ 45 Z = 120 mm R = 165 mm @ 45 R = 110 mm R = 165 mm R = 110 mm R = 165 mm R = 110 mm @ 45 R = 140 mm @ 45 R = 165 mm @ 45 1/5/2017 2-nd harmonic cavity meeting 13

Relative case Relative case- -to to- -case change of the transfer function the transfer function case change of Graphs illustrate the table. Here the value of the transfer function change (in the percentage points) relative to the ideally transparent shell at the start of the injection is shown for every data point as a function of the case number (options 1 11). Filled markers refer to the first block (Z = 0) and the markers without filling are for the points in the last block (Z = 120 mm). Connecting line is added for convenience to follow the change of the transfer function for every sampling point. Cases 0 (magnetically transparent shell) and 1 (azimuthally symmetric design) are not shown in the figure. Although transfer functions for the eight segments design (cases 9 11) are different from those for the four segments case with the slots (cases 6 8), this difference is purely quantitative, not qualitative. 1/5/2017 2-nd harmonic cavity meeting 14

Next: Next: 1. Iterate on the shell design, including the cooling. 2. Finalize the bias coil current shape. 1/5/2017 2-nd harmonic cavity meeting 15