Effective Quality Improvement Tools and Problem Definition Techniques

Explore various quality tools such as Cause-Effect diagrams, Pareto charts, and Process flow charts, along with techniques for defining problems effectively. Understand the importance of quantified problem statements and the relationship between variables in quality improvement efforts.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

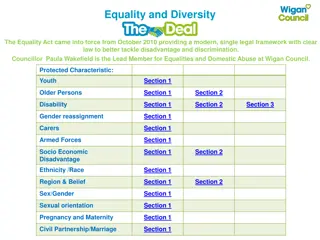

Chapter 7 Quality Tools

Which tool is best? Tools can serve as the backbone for virtually any type of quality improvement effort (Six Sigma, TQM, 8D) Graphical representations of data help us understand the true importance of data. There is no single one-size fits all solution. Every project and problem is different.

Diagnostic Tools Analytical Tools: Cause-Effect (CE) diagram Failure mode-effects Analysis (FMEA) XY matrix Affinity diagram Fault tree analysis (FTA) Graphical Tools: Histogram Boxplots Probability distribution plots Main-effects plots Pareto charts Run charts Multi-Vari charts Time-series plots Scatter plots

Diagnostic Tools Other Tools: Checksheets Scorecards Graphical Rep. of Process: Process flow charts Process mapping Cross-functional mapping Deployment diagram Supplier-input-process- output-customer (SIPOC) diagram Input-process-output (IPO) diagram Force-field analysis

Problem Definition A good problem definition will include quantified information about the problem, the magnitude of the problem, the baseline, and the gap remaining to reach a benchmark or desired state Be Specific Use declarative format Quantify Be factual Example of poor problem definition: Reduce restorable time for severity 1 telephone banking problems, focusing on human errors as root cause Example of good problem definition: Reduce restorable time from 51% per month for severity 1 telephone banking problems to 30% or less per month by the third quarter of this year, resulting in annual savings of $4.5M

Y = f (x) The transfer equation of Y=f(x) where X =x1, x2, x3, ,xn recognizes that a causal relationship exits in any process of action performed. Y is a function of one or many x s where Y is the dependent variable and the x s are independent variables. X can equal quality, delivery time, cost of the product. Therefore Critical to Satisfaction refers to any variable that has significant influence on one of more of the determinants of customer satisfaction. Pareto principal suggests that 80% of the of the total error or variance will be caused by 20% of the variables. These are the vital few , while the remaining are the trivial many . The key is to identify these vital few. x1 x2 x3 . . . . xn Process Inputs . . . Uncontrollable variables or factors (noise)

Critical-to (CT) Definitions Critical-to-Satisfaction (CTS) characteristics expression of the customer s vital needs. Critical-to-Quality (CTQ) characteristics- the product, service and/or transactional characteristics that significantly influence one or more CTS in terms of quality. Critical-to-Delivery (CTD) characteristics- in terms of delivery. Critical-to-Cost (CTC) characteristics- in terms of cost. Critical to Satisfaction Delivery Quality Price CTD CTD CTD CTQ CTQ CTQ CTC CTC CTC CTP CTP CTP Variables (X) Critical-to-Process (CTP) characteristics- Process parameters that significantly influence a CTQ, CTD, and/or CTC.

The Leverage Principle Not all X variable affect the outcome (Y) equally. In Six Sigma process: Identify the variables that exert strong influence (Vital Few). Then we must focus on controlling these variables. Design of Experiments (DOE) is used to achieve this objective. Y X (x1, x2, x3, ,xn ) Independent Input-process Cause Problem Control Dependent Output Effect Symptom Monitor

The Leverage Principle (Variation Reduction Strategies) Total Red. Efforts 1 2 3 4 5 6 Total Strategy % Impr. Baseline 4 11 3 2 1 1 -- 12.33 Reduce each by 1 3 10 2 1 0 0 6 10.68 13.4% Eliminate all but one 0 11 0 0 0 0 11 11.00 10.8% Reduce the vital one 4 8 3 2 1 1 3 9.75 20.9% 6 = j = 2 j Total 1

What does measurement mean? Concept of measurement: seek to compare or contrast a physical attribute of something to a rational and invariant standard performance gap Seek to quantify such gaps for purposes of communications, verification, and analysis. Measure subjective matter (customer satisfaction) through surveys, questionnaires Measure physical characteristics, time characteristics, defect rates .

How do we know if customers are happy? Goal is to understand how to better satisfy the customer Survey design considerations: Length (not too long) Appearance (simple, not busy) Types of questions (statements of fact or measures of performance or importance) Types of question formats: Closed-ended (yes/no) Rating scales Open-ended questions / probes Other considerations: Focus on one theme Usually best to include a midpoint in rating scales (i.e. odd number) Try to solicit feelings toward your competitors. Identify specific target control groups: At least 10% of customer base Stratify various customer segments Give prior notice, before delivering survey Personalize the survey and cover letter Address confidentiality Offer an incentive or token of appreciation for completion Follow up with a friendly collection strategy Develop action plans that are based on results Communicate results to customers Follow up with repeat surveys to monitor changes over time

Likert scale A subjective scoring system that allows a person being surveyed to quantify likes and preferences on a 5-point scale, with 1 being the least important, relevant, interesting, or other, and 5 being most excellent, important, etc Strongly Agree / Agree / Undecided / Disagree / Strongly Disagree Very Frequently /Frequently /Occasionally /Rarely /Very Rarely /Never Very Important / Important / Moderately Important / Of Little Importance / Unimportant Excellent / Above Average / Average / Below Average /Extremely Poor Almost Always True / Usually True / Often True / Occasionally True / Sometimes But Infrequently True / Usually Not True / Almost Never True

Continuous Scales If the data are nonlinear (i.e., with a very wide range of values), then a logarithmic scale (in this case base 10) may be more appropriate. Linear Scale: A scale with equal divisions for equal values 7000 6000 5000 4000 3000 2000 1000 0 0 10 20 30 40 50 60 Forecast Period (in Months)

Analytical Tool: Cause-Effect (CE) Analysis CE diagram (fishbone diagram) uses collective knowledge to identify the main causes (x) of the effect (y) under study. Manufacturing diagrams (Six M s: measurement, manpower, machines, materials, methods, and mother nature). Transactional diagrams (4 P s :Policies, procedures, personnel, environment). Graphical way to show relationships between inputs and outputs. Label each cause with a C (fixed variable), N (Noise) or X (experimental independent variable.) CE Diagrams can be constructed using MINITAB (page 156-157)

Cause-Effect (CE) Analysis www.syncfusion.com/.../img/Fishbone_larger.png

Analytical Tool: Failure Mode Effects Analysis (FMEA) Used to assess risks from potential product , service, transaction or process failure modes. Widely used in the Analyze and Improve phase, can also be used in Control phase. Helpful to assist in: Improving or designing more robust products, services & processes Designing safer products and processes Designing safer delivery systems Receiving fewer complaints and reducing the organization s guarantee costs Creating fewer problems or minimizing them in everyday business processes Provide improvement teams with prioritized causes and identifying which causes need to be eliminated urgently.

How does FMEA work? Focus on Severity, Occurrence and Detectability of each process. Then calculate the the Risk Priority number (RPN) Each organization can define their own scale (1-10, 1-5 )as long as they are consistent across the organization. Example of FMEA analysis for Auto manufacturer Start with a grid to define the potential failures P R P S E VCauses O C CControls D E T R P NActions P S P O P D N Product or Process Failure Mode Failure Effects Plans Engine Overheat Engine Damage Doesn't retain charge Battery Car doesn't start Brakes Brake failure Can't STOP car

FMEA Severity, Occurrence & Detectability Rating Criteria Is not noticed by anybody, has no effect Is not noticed, has only an insignificant effect Causes only small irritations 1 SEVERITY 2 3 S E VCauses O C CControls Modest loss of performance Fall in performance level; consequence is customer's complaints Fall in performance level that disturbs the capacity to function Disturbed capacity function that leads to an increase in customer dissatisfaction Product or service becomes useless 4 Product or Process 5 Failure Mode Failure Effects 6 Engine Overheat Engine Damage Doesn't retain charge 7 Battery Car doesn't start 8 Brakes Brake failure Can't STOP car 9 Product or service is illegal Customer or employee is injured or killed. 10

FMEA Severity, Occurrence & Detectability Rating Criteria Probability OCCURANCE Once every 6-100 yrs <2/1,000,000,000 1 Once every 3-6 yrs <3/10,000,000 2 Once every 1-3 yrs <6/1,000,000 3 S E V O C C Controls Check frequently D E T R P NActions Once a year <6/100,000 4 Product or Process <1/10,000 Failure Mode Failure Effects Engine Damage Once every 6 months 5 Causes Radiator hose worn Once every 3 months Engine <0.33% 6 Overheat Doesn't retain charge 8 5 Once a month <1% 7 Car doesn't start Can't STOP car Dry/dead battery worn brakepads Service History Replace worn pads Battery <5% 8 4 Once a week 8 Every 3 to 4 days Brakes <30% 9 Brake failure 10 2 More than once a day >30% 10

FMEA Severity, Occurrence & Detectability PROBABILITY OF DETECTION Rating Criteria The cause of the failure is obvious and can be hindered simply All units are to be inspected automatically 1 Risk Priority number (RPN) is calculated by multiplying Severity x Occurrence x Detectabillity 2 Statistical process controls with a systematic failure cause test and corresponding Actions 3 Statistical process controls are to be conducted with a systematic failure cause test. 4 Statistical process controls are to be conducted 5 S E V O C C Controls Check frequently D E T R P N Product or Process Failure Mode Failure Effects Engine Damage All units are to be inspected manually and avoidance actions installed All units are to be inspected manually Manual inspections are to be conducted frequently Manual inspections are to be conducted occasionally. The defect caused by the failure is not detectable 6 Causes Radiator hose worn Actions Replace Radiator Hose 7 Engine Overheat Doesn't retain charge 8 5 1 40 Car doesn't start Can't STOP car Dry/dead battery worn brakepads Service History Replace worn pads 8 Battery 8 4 1 32 Change Battery Revise Brakes frequently 9 Brakes Brake failure 10 2 8 160 10

Analytical Tool: XY Matrix XY matrix allows everyone involved with a process to agree on output (y s) critical to the survey, transaction and/or customer. Matrix allows the team to assign the level of importance of each variable (x) to the output (y). EXAMPLE of XY matrix as relates to a coffee house. OUTPUT VARIABLES (Y) Flavor Aroma 10 Price Acidity RANK %RANK Rankings 10 10 2 Coffee Type Coffee Amount Grind Time Water Temp Cup Type Cup Size Brew Time 10 9 9 9 2 2 9 10 7 6 3 4 4 6 10 10 2 2 4 5 2 10 10 3 2 2 1 2 320 280 176 144 104 112 174 1310 24.4% 21.4% 13.4% 11.0% 7.9% 8.5% 13.3% INPUT VARIABLES (X) If the results/ranking were generated during a brainstorm session than they should be verified based on actual data.

Graphical Tool: Pareto Charts Pareto charts help identify the top factors ( vital few ) Order X in descending order. Add a line showing cumulative % of total. Coffee Pareto Chart 1400 100.0% 90.0% 1200 80.0% 1000 70.0% 60.0% 800 RANK 50.0% Based on this which inputs would you focus on to insure customer satisfaction? 600 40.0% 30.0% 400 20.0% 200 10.0% 0 0.0% Coffee Type Coffee Amount Grind Time Brew Time Water Temp Cup Type Cup Size Count 320 280 176 174 144 112 104 Percentage 24.4% 21.4% 13.4% 13.3% 11.0% 8.5% 7.9% Cumulative % 24.4% 45.8% 59.2% 72.5% 83.5% 92.1% 100.0%

Graphical Tool: Histogram with Normal Curve university-software.com/NormalHist.jpg

Graphical Tool: Histogram with Normal Curve Minitab: Calc Random Data Integer Stat Basic Statistics Graphical Summary

Graphical Tool: Boxplot Minimum Maximum Median First Quartile Third Quartile Minitab: Stat Basic Statistics Display Descriptive.. Boxplot

Graphical Tool: Probability Plot Minitab: Graph Probability Plot Single

Graphical Tool: Main-Effects Plot Main-effects plot graphically compares the level of a process output variable at various states of process factors Lines with steeper slopes have larger impact on the output compared to those lines with little or no slope Used to present result from analysis of variance (ANOVA) Use to examine the level means for each factor, compare the level means for several factors and compare the relative strength of the effects across factors

Graphical Tool: Main-Effects Plot MINITAB STAT ANOVA Main Effect Plot Input Output 60 83 72 71 74 69 X1 0 1 0 1 0 1 X2 X3

Graphical Tool: Run Chart A line graph of data points plotted in chronological order that helps detect special causes of variation Understand process variation Analyze data for patterns Monitor process performance Communicate process performance

Graphical Tool: Run Chart www.pqsystems.com/.../chart_BasicRunChart.png

Graphical Tool: Time-Series Plot A time series plot is a graph showing a set of observations taken at different points in time and charted in a time series. Outliers: values that do not appear to be consistent with the rest of the data Discontinuities: a break or gap in a process that would normally be continuous Trends: a general tendency in movement or direction Periodicities: any recurrence at regular intervals

Graphical Tool: Time-Series Plot cookbooks.opengrads.org/images/3/3b/Precip_ti..

Graphical Tool: Multi-Vari Charts Show patterns of variation from several possible causes on a single chart, or set of charts Obtains a first look at the process stability over time. Can be constructed in various ways to get the best view . Positional: variation within a part or process Cyclical: variation between consecutive parts or process steps Temporal: Time variability

Graphical Tool: Multi-Vari Charts Cus. Size Product Cus. Type Satis. 3.54 3.16 2.42 2.70 3.31 4.12 3.24 4.47 3.83 2.94 Cus. Size: 1 = small 1 2 1 2 1 2 2 2 2 1 1 1 2 2 1 1 2 2 1 1 2 3 2 2 3 2 1 2 2 1 2 = large Product: 1 = Consumer 2 = Manuf. Cus. Type: 1 = Gov t 2 = Commercial 3 = Education http://www.qimacros.com/qiwizard/multivari-chart.html

Graphical Tool: Multi-Vari Charts Minitab: Stat Quality Tools Multi Vari Chart

Graphical Tool: Scatter Plot Show patterns of variation from several possible causes on a single chart, or set of charts Obtains a first look at the process stability over time. Can be constructed in various ways to get the best view . Positional: variation within a part or process Cyclical: variation between consecutive parts or process steps Temporal: Time variability

Graphical Tool: Scatter Plot http://mste.illinois.edu/courses/ci330ms/youtsey/scatterinfo.html

Graphical Tool: Scatter Plot http://mste.illinois.edu/courses/ci330ms/youtsey/scatterinfo.html

Graphical Tool: Scatter Plot http://mste.illinois.edu/courses/ci330ms/youtsey/scatterinfo.html

Graphical Tool: Scatter Plot http://mste.illinois.edu/courses/ci330ms/youtsey/scatterinfo.html

Graphical Tools for Process Rep.: Process Flowcharts Visual representation of the major process steps. Useful to compare as is with should be process. 1. Determine the limits of the process. Clearly define where it begins & ends. 2. Determine the steps in the process 3. Put the steps into sequence 4. Draw the flow using standard symbols. Add arrows to show flow direction. 5. Verify the flow is complete. Is every feedback loop complete? Standard symbols: Stop/ Start Decision Point Activity Connector (to another page or diagram)

Graphical Tools for Process Rep.: Process Flowcharts www.breezetree.com/.../8D -process-flowchart.png

Graphical Tools for Process Rep.: Process Mapping Process mapping is a workflow diagram to bring forth a clearer understanding of a process or series of parallel processes Cross-Functional Mapping As-is vs. To-be

Graphical Tools for Process Rep.: Process Mapping www.oregon.gov/.../images /iGrafx_Process_Map.JPG

Graphical Tools for Process Rep.: SIPOC Diagram Supplier-Input-Process-Output-Customer diagram. A high-level picture of the process that depicts how the given process is servicing the customer. Useful to discover customer pain points Identify key Y s an X s with project team. Suppliers Inputs Process Outputs Customers Repeat (daily) New Machine manufacturer Bean supplier Filter supplier Cup supplier Coffee beans Water Filter Cup Brewing machine Coffee Espresso Insert simple flow-chart here

Graphical Tools for Process Rep.: SIPOC Diagram http://www.ptm-consulting.it/immagini/sipoc.jpg

Graphical Tools for Process Rep.: IPO Diagram Input-Process-Output diagram is another visual rep. of a process activity. Based on the transfer equation y=f(x) Fixed Variables (C) Process X s x1=Forecast x2=Buyer X3 =AVL x4=BOM x5=LT x6=Market Dollar Value Y=Lack of materials supplies Process Program Management Noise Variables(N)

Graphical Tools for Process Rep.: SIPOC Diagram http://www.variancereduction.com/newsletters/images/9.6.16.jpg

Other Tools: Force-Field Analysis Force-Field Analysis was developed by Lewin (1951) and is widely used to inform decision-making, particularly in planning and implementing change management programs in organizations. It is a powerful method for gaining a comprehensive overview of the different forces acting on a potential policy issue, and for assessing their source and strength.

Force -Field Analysis