Effective Strategies for Setup Time Reduction in Production Facilities

Explore the impact of setup time on production efficiency, batch sizes, and throughput in manufacturing processes. Learn how adjusting setup batch sizes can optimize flow time and capacity. Dive into practical examples and calculations to understand the effects of batch size on effective capacity.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

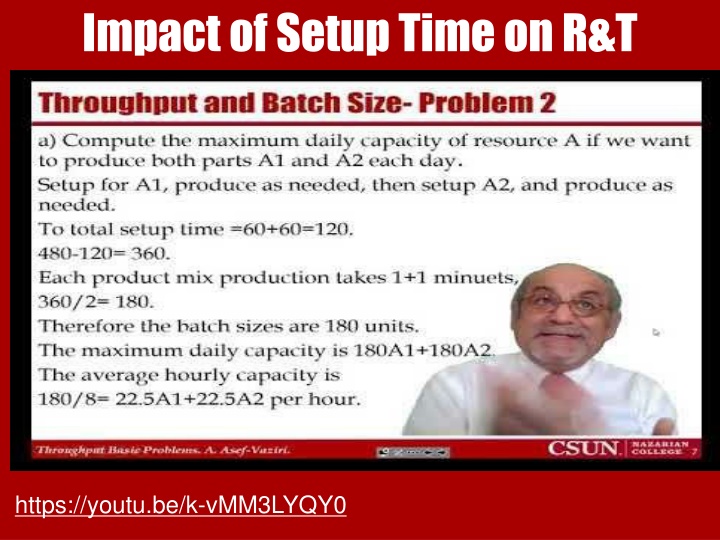

Impact of Setup Time on R&T https://youtu.be/k-vMM3LYQY0

Setup Batch and Total Unit Load Setup or Changeover: activities related to cleaning, resetting and retooling of equipment in order to process a different product. Q : Setup batch or lot size; the number of units processed consecutively after a setup. S:Average time to set up a resource at resource pool p for a particular product Average setup time per unit is then S/Q S/Qis also included in Tp Throughput Basic Problems. A. Asef-Vaziri. 2

Setup Batch Size: Throughput or Flow Time What is the right lot size or the size of the set up batch? Lot Size or ? The higher the lot size, the lower the unit load and thus the higher the capacity. The higher the lot size, the higher the inventory and therefore the higher the flow time. Reducing the size of the setup batch is one of the most effective ways to reduce the waiting part of the flow time. Load batch: the number of units processed simultaneously. Often constrained by technological capabilities of the resource. Setup batch: the number of units processed consecutively after a setup. Setup is determined managerially. Throughput Basic Problems. A. Asef-Vaziri. 3

Throughput and Batch Size- Problem 1 Product Mix: 50%-50% Set-up time 30 min per product Working hours 8 hours/day 10 min/unit A Operation D 20 min/unit 1 machine 100% available Compute the effective capacity under min cost strategy. Two set-ups each for 30 min = 60 mins An aggregate product (formed by 1A+1D) takes 10+20 = 30 Production time = 8*60-60 = 420 mins Capacity = 420/30 = 14 aggregate units Each aggregate unit is 1A and 1B (total of 14A and 14D). Throughput Basic Problems. A. Asef-Vaziri. 4

Throughput and Batch Size- Problem 1 Now suppose we produce in batches of two units of each product. Two setups each for 30 min = 60 mins. Production time = 2 10+2 20= 60 mins. Production time of each batch = 60+60=120 mins. Production time of an a aggregate product = 120/2=60 Each aggregate unit is 1A+1D Capacity = 480/60= 8 aggregate products. That is a total of 8A and 8D. Throughput Basic Problems. A. Asef-Vaziri. 5

Throughput and Batch Size- Problem 2 Resource A Resource D Activity A1 Activity D Activity A2 TpA1 = 1 min SpA1 = 60 min TpA2 = 1 min SpA2 = 60 min SpD= 0 min TpD= 10 min c=1, c=2. Resource A is responsible for two activities: A1&A2. Activity A1 produces part A1 and activity A2 produces part A2. TpA1=TpA2=1 minute per part. When we switch from one part to another, there is 60 minutes setup time. Volume of production of the two parts must be equal. A day is 8 hours. Throughput Basic Problems. A. Asef-Vaziri. 6

Throughput and Batch Size- Problem 2 a) Compute the maximum daily capacity of resource A if we want to produce both parts A1 and A2 each day. Setup for A1, produce as needed, then setup A2, and produce as needed. To total setup time =60+60=120. 480-120= 360. Each product mix production takes 1+1 minuets, 360/2= 180. Therefore the batch sizes are 180 units. The maximum daily capacity is 180A1+180A2. The average hourly capacity is 180/8= 22.5A1+22.5A2 per hour. Throughput Basic Problems. A. Asef-Vaziri. 7

Throughput and Batch Size- Problem 2 b) Compute the capacity of Resources A if parts A1 and A2 are produced in batches of 60 units. For each batch of A1 we need 60+60 1=120 For each batch of A2 we need 60+60 1=120 We need 240 minutes for 60A1 and 60A2 The average throughput per minute is 60/240 for 1A1 and 1A2. That is 0.25 per minute or 0.25 60=15 pairs of parts A1 & A2 per hour. c) These parts then go to Resource D and are assembled with part D. Suppose TpD= 10 mins and there is one resource unit in Resource pool D. What batch size makes the capacity of the two Resources of A and D equal? Cycle time for resource D is 10 mins. Q = Batch size for A1 or A2. Throughput Basic Problems. A. Asef-Vaziri. 8

Throughput and Batch Size- Problem 2 (120+2Q) minutes to produce QA1 and QA2. Therefore, the average cycle time to produce 1A1+1A2 is (120+2Q)/Q= 2+120/Q CT(A1&A2) = CT(D) 2+120/Q= 10 120/Q = 8 8Q=120 Q=15 batches 15A1 and 15A2. d) Suppose we have added a second resource unit to the resource pool D to increase the production of part D. What batch size makes the capacity of the two Resources of A and D equal? Cycle time of resource D is 5 mins. That is Rp=2/10 =0.2 CT=1/Rp=5 Throughput Basic Problems. A. Asef-Vaziri. 9

Throughput and Batch Size- Problem 2 2+120/Q=5 120/Q=3 Q= 40 A more difficult way to solve (c) and (d) parts a) Time to produce 1A1 and 1A2 = (120+2Q)/Q =TpA RpA=1/TpA RpA= 1/[120+2Q]/Q]= Q/(120+2Q) RpA=RpD Q/(120+2Q) = 1/10 10Q=120Q+2Q 8Q=120 Q=15 produce batches of 15 pairs of A1 and A2 in each batch d) TpD=2/10 Q/(120+2Q)=2/10 10Q = 240+4Q 6Q=240 Q = 40 Throughput Basic Problems. A. Asef-Vaziri. 10