Efficient Heat Exchanger Operation for Cost Savings

Efficient operation of heat exchangers is crucial for reducing production costs and optimizing energy usage. This involves predicting fouling, determining maintenance needs, and calculating charges due to efficiency losses. By maintaining optimal operation, companies can save resources, reduce maintenance costs, and improve productivity. Regular cleaning and maintenance help prevent issues like corrosion and tube replacement, leading to smoother operation and extended equipment lifespan. Regaining blocked tubes can enhance capacity and efficiency, resulting in energy savings and improved equipment performance. Overall, prioritizing optimal heat exchanger operation can lead to fewer repairs, lower emissions, and enhanced equipment longevity.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

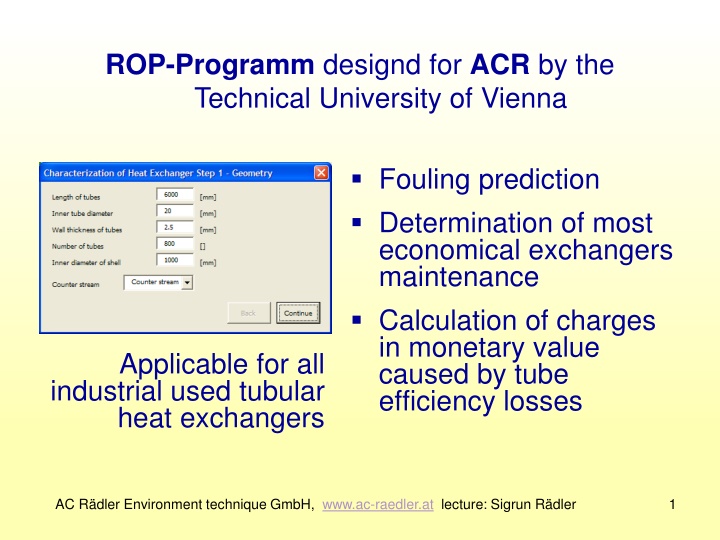

ROP-Programm designd for ACR by the Technical University of Vienna Fouling prediction Determination of most economical exchangers maintenance Calculation of charges in monetary value caused by tube efficiency losses Applicable for all industrial used tubular heat exchangers AC R dler Environment technique GmbH, www.ac-raedler.at lecture: Sigrun R dler 1

Fouling process is predicted immediately: Increased Temperature/Energy Growing of Fouling in days Loss of Capacity 2 AC R dler Environment technique GmbH, www.ac-raedler.at lecture: Sigrun R dler

Feature for operation cost: Company own figures are put (in the masque) and are computed regarding cost of - energy - stand still - capacity loss AC R dler Environment technique GmbH, www.ac-raedler.at lecture: Sigrun R dler 3

Exchanger efficiency losses in Monetary Value Loss during operation Cost of maintenance Cleaning point AC R dler Environment technique GmbH, www.ac-raedler.at lecture: Sigrun R dler 4

Improved productivity save resources and cost 1) Legend: Last slide indicates the source of following outcome Efficient exchanger operation is the simplest way to reduce production costs Chemical cleaning cause rough inner tube surface which lead to faster fouling, to earlier corrosion and tube replacement Smooth inner tube surface prolong optimal exchanger operation Regular cleaning diminish corrosion failure AC R dler Environment technique GmbH, www.ac-raedler.at lecture: Sigrun R dler 5

Regaining of blocked tubes improve exchangers operation capacity with RTC possible to regain Regaining of fully exchangers efficiency contributes to energy saving, capacity improvement and at least to improve exchangers life cycle. Optimal exchanger operation further contributes to: less pump pressure less repairs less problems before or end of pipe equipment reduction of emissions AC R dler Environment technique GmbH, www.ac-raedler.at lecture: Sigrun R dler 6

Optimal maintained heat exchangers may avoid to much oversized exchanger design Oversized exchangers capacity vary from 10 % to 300 % 25 % of oversized exchanger design will increase investment cost up to 12 % Parallel connected exchangers, which are optimal maintained: Minimise efficiency loss Minimise production loss (no stand still) Reduce corrosion failure Contribute to plant harmonization, improve production quality and double exchangers life cycle AC R dler Environment technique GmbH, www.ac-raedler.at lecture: Sigrun R dler 7

Legend: 1) Book: published by PP Publico Publication, Germany Heat Exchanger Fouling, Mitigation and Cleaning Technologies by Prof. H. M ller-Steinhagen, Dr. H. U. Zettler, AC R dler Environment technique Ltd. A-1220 Vienna, Leonard-Bernstein-Street 8/2/23.8 + 43(0) 676 374 65 09 + 43(0) 676 616 99 22 office@ac-raedler.at www.ac-raedler.at AC R dler Environment technique GmbH, www.ac-raedler.at lecture: Sigrun R dler 8