Efficient Storage Structures for Minimizing Post-Harvest Losses

Post-harvest losses in India can be reduced significantly through proper storage structures and techniques. Learn about the importance of cleaning, grading, and drying produce for safe storage. Discover various types of storage structures used by farmers and the requirements for an ideal storage facility to ensure maximum protection and longevity of stored seeds.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

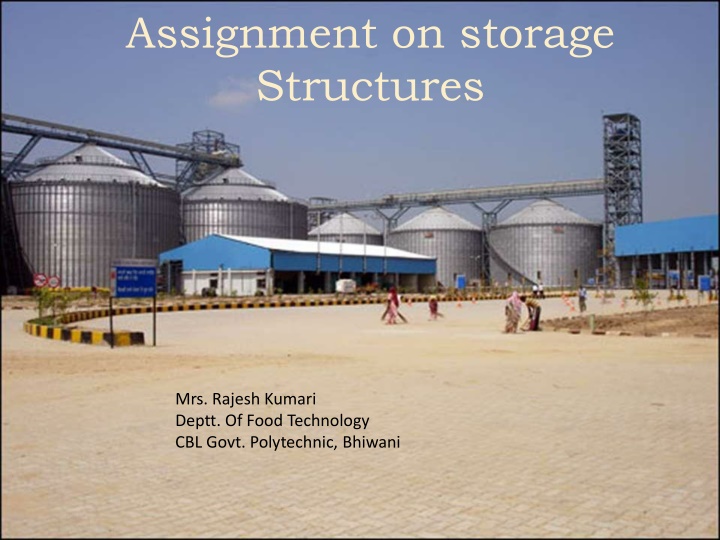

Assignment on storage Structures Mrs. Rajesh Kumari Deptt. Of Food Technology CBL Govt. Polytechnic, Bhiwani

STORAGE STRUCTURES Post harvest losses in India are estimated to be around 10 per cent, of which the losses during storage alone are estimated to be 6.58 per cent. But, with the advent of improved agricultural technology, the producer canafford to store the seeds for longer period with minimum loss. But, with the advent of improved agricultural technology, the producer can afford to store the seeds for longer period with minimum loss.

For best storage performance The produce must be thoroughly cleaned and graded, Dried to the safe storage moisture level of 10-12 % for cereals and 7-9% for oil seeds (on wet basis) for a safe storage period of 6-12 months. Storage structures should to be properly repaired, cleaned and disinfected, Structures should bear the load of seeds stored and do not permit contact/exchange with outside humid air, Structures should be constructed in the coolest part of the house/ farm.

An ideal storage facility should satisfy the following requirements 1) It should provide maximum possible protection from ground moisture, rain, insect pests, moulds, rodents, birds, fore etc., 2) It should provide the necessary facility for inspection, disinfection, loading, unloading, cleaning and reconditioning. It should protect grain from excessive moisture and temperature favourable to both insect and mould development, It should be economical and suitable for particular situation 3) 4)

Type of storage (a) Open storage (b) Bag storage

Storage structures used by the farmers are 1.Gunny bags of different capacities (35, 50, 75 and 100 kg with or without inside plastic lining ) . 2. Mud bins having 100 1000 kg capacity

3. Baked In heaps on flat floor in the corner of houses (100- 1500 q) 4.Earthen containers of 5- 100 kg capacity 5. Bamboo structures

6.Wooded bins 7. Underground structures

IMPROVED RURAL - LEVEL STORAGE STRUCTURES 1. Bitumen/ coal tar drum: An alternate model of metal bin, low cost Diamensions - 520 mm dia and 900 mm height Capacity-1.5 q of wheat and 1.2 q of Bengal gram.

2.Hapur bin/ Kothis: Circular bins Capacities- 2, 5, 7.2 and 10 q Potential to meet requirements of even large farmers. 3. Udaipur bin These bins are made out of used coaltar drums. Stock capacity- 1.3 q of wheat and maize. Storage time-short duration Adopted by small farmers. 4. PKV bin Material- bamboo splits into suitable sizes. The tunnel, outlet flap valve and complete stand can be fabricated in a workshop

5. Stone bin Material-40 mm thick stone slabs ( 680 mm x 1200 mm) Inlet and outlet -asbestos. Capacity of - 3.8 q. 6. Bamboo bin Material -two walls of bamboo with polythene lining in between and have varying capacities. Storage time -short duration Adopted by small and marginal farmers.

7. Pusa bin Modification of the ordinary mud storage structure Modification-polyethylene film of 700 gauge thickness has been embedded at the top, bottom and on all the sides of the mud bin The construction of outer walls with burnt bricks up to 45 cm height makes the structure rat proof as well. Durability- one year 8. Pusa Cubicle This is a room like structure ( 3.95 x 3.15 x 2.60 m), a modification of Pusa bin 3.73 m x 2.93 m x 0.07 m is made with unburnt bricks on a concrete floor (except 22 cm of outer sides with burnt bricks). A polyethylene sheet is placed on this platform and another platform of similar dimension is made with unburnt bricks. The 22 cm thick inner walls are constructed upto 2.6 m height. A wooden frame of 1.89m x 1.06 m for door is fixed in the front side of 3.95 m wall. The roof can be made by wooden beam placed at 15 cm distance and covered with unburnt bricks. Capacity -24 tonnes

9. Baked clay bin Material- 16 burnt rings jointed by mud plaster; cement mortar and cowdung coatings one after another. The top is covered with a mild steel lid. low cost 10. Pusa Kothar Presently storage is practiced in small compartments of a room (5.3 m x 2 m x 4 m) called kothar. Wall three filling holes each of 0.5 m x 0.5 m size Two out lets of G.I. sheets of 15 cm dia. and 30 cm 11. Metal bins Bins made of steel, Aluminium R.C.C are used for storage of grains outside the house. These bins are fire and moisture proof. The bins have long durability and produced on commercial scale. The capacity ranges from 1 to 10 tonnes. In Haryana , mostly this type of bins are used for storage of wheat for family

STACKING Food grains have to be stored and preserved on scientific lines in godowns till they are issued to consumer. The bags containing food grains cannot be just dumped inside the godown, for it will not facilitate proper storage. Proper stacking ensures free access to the stocks in all parts of the godown for inspection and helps in effective disinfestations work. Generally, three methods of stacking are being followed: 1. Simple, 2.Cross and 3. Block method.

Brick-build Godowns They are made by brick walls with cemented flooring for storing paddy/rice in bulk and bags.

CAP(cover and plinth) Storage It is an economical way to storage on a large scale. The plinth is made by cement concrete and bags are staked on open and cover by polyethene cover.

Silos Silos are used for storage foodgrains. These are made from concrete, bricks and metallic materials with loading and unloading equipment.