Effluent Treatment Plant in Waluj MIDC Industrial Area

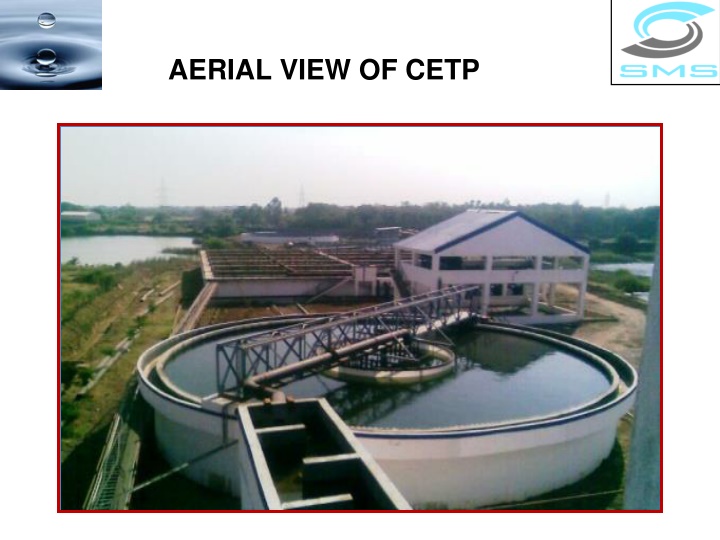

Common Effluent Treatment Plant (CETP) in Waluj MIDC Industrial Area is a successful project jointly implemented by MIDC, Waluj Industrial Association, and Maharashtra Pollution Control Board. The plant treats effluent generated by industrial units using conventional technology approved by IIT Mumbai. With a capacity of 10 MLD and operational since 2011, the CETP handles various types of effluents including hexavalent chromium, phenolic, lead, zinc, and fluoride. The project cost 17 Crs and has been running smoothly with active cooperation from stakeholders. Technical features include sludge handling by mechanical means and treatment schemes involving primary, secondary, and tertiary processes.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

ABOUT CETP Common Effluent Treatment Plant for Treating of Effluent generated by Industrial units in Waluj MIDC Industrial Area was conceived as a joint efforts between MIDC,Waluj Industrial Association and Maharashtra Pollution Control Board. Association decided to call for a bid from relevant technical expert party for designing, erectioning,commissioning and operation of CETP. SMS Infrastructure Limited was selected for implementation of this project on BOOT basis for 17 yrs. As per the agreement an SPV in the name of M/s. SMS Waluj CETP Pvt. Ltd. was formed. The project is running successfully through Active co-operation from the industrial association and officials of MIDC and MPCB.

TECHNICAL FEATURES Scheme is approved by IIT, Mumbai Plant working on Conventional Technology Sludge handling by mechanical means : Filter press Dewatered sludge will be stored temporarily and transported to MPCB approved TSDF site at Ranjangaon

TECHNOLOGY PROCESS DETAILS CAPACITY 10 MLD and 20% overloading PROJECT START UP 2007 PROJECT COMMISSIONED June 2011 PROJECT COST 17 Crs. For 10 MLD Plant : Infrastructures like Eff. Collection Sumps, Pumping Stn., etc. is provided by MIDC, Aurangabad.

CETP HIGHLIGHTS PLANT CAPACITY : 10 MLD with 20 % overloading. TOTAL PLOT AREA : 133650 SQ.M TOTAL BUILT UP AREA : 7052.135 SQ.M TREATMENT SCHEME : PRIMARY,SECONDARY, TERTIARY.

HEXAVALENT CHROMIUM EFFLUENT PHENOLIC EFFLUENT Effluent storage Effluent storage Reaction of effluent with H2O2 in acidic medium Reaction of effluent in acidic medium Clarification of effluent Clarification of effluent Clear water storage Clear water storage Phenolic Sludge removal Chrome Sludge removal to Homogenization Tank or Intermediate storage Tank

LEAD EFFLUENT ZINC EFFLUENT FLUORIDE EFFLUENT Effluent storage Effluent storage Effluent storage Reaction of effluent with Sodium bisulfite Reaction of effluent with Zinc hydroxide Reaction of effluent with Calcium fluoride Clarification of effluent Clarification of effluent Clarification of effluent Clear water storage Clear water storage Clear water storage Lead Sulfite Sludge removal Zinc Fluoride Sludge removal Sludge removal Homogenization Tank or Intermediate storage Tank

TECHNOLOGY PROCESS DETAILS TREATMENT TECHNOLOGY: Extended Aeration Activated Sludge Process MODE OF RECEIVING EFFLUENT IN CETP: Underground drainage pipeline network FINAL DISCHARGE POINT: Kham River : Through underground pipeline and gardening SLUDGE DISPOSAL: Member of Hazardous Waste Management Facility

PROCESS FLOW CHART EFFLUENT Effluent Grit Removal from Special Treatment Section Screening followed by Oil & Grease Removal To Filter Press Homogenization Coagulation & Flocculation Nutrients & Food Chemical Sludge Storage Primary Clarification Kham River disposal Aeration ASP Biological Sludge Storage Secondary Clarification Filtration & Adsorption Disinfection, Oxidation if required To Filter Press Final Treated Water Storage Intermediate Storage

THANK YOU COMMITTED TO CLEANER ENVIRONMENT