Effluents from Fertilizer Industry - Pollutants and Treatment Details

The effluents from the fertilizer industry contain a variety of pollutants such as Ammonia, Nitrates, Urea, and more. This content delves into the contaminants found in effluents from Nitrogenous Fertilizer and Phosphatic Fertilizer operations, along with insights on treatment processes. Learn about the environmental impact of these pollutants and how they are managed to reduce water pollution.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

B.Sc. (H) CHEMISTRY Semester VI, Jan Jun 2020 CHEMISTRY - DSE PAPER - INDUSTRIAL CHEMICALS AND ENVIRONMENT Unit Environment and its segments (Water Pollution-Part-II) Effluents from Fertilizer Industry and their Treatment BY RITU MALIK Assistant Professor RAJDHANI COLLEGE UNIVERSITY OF DELHI

Effluents from fertilizer industry The main pollutants from the fertilizer industry are listed below: (a) Ammonia and ammonium salt; (b) Suspended solids and ash; (c) Acids and alkalis; (d) Oil; (e) Arsenic, ME A and methanol; (f) Nitrates; (g) Urea; (h) Cooling water conditioning chemicals like chromate, phosphates, biocides, etc.; (i) Cyanides and sulphides; (J) Biochemical oxygen demand; (k) Fluorides; and (l) Phosphates, etc.

Nitrogenous Fertilizer Industry Nitrogenous Fertilizer Industry (Different Contaminants with their concentrations from various operations) Different Contaminants with their concentrations from various operations) a. Cooling Tower Blow Down:

Continued... b. Water Treatment Plant: The main effluents from the water treatment plant of a nitrogenous fertilizer is urea. Its concentration varies with the quantity of raw water used. The major contaminants in this effluent are anions and cations. Other effluents include sodium hydroxide, sulfate ions and ammonia.

Continued.. c. Boiler Blow-Down:

Continued .. d. Ammonia Plant:

Phosphatic Fertilizer: Phosphatic Fertilizer: (Different contaminants and their concentrations from various operations) Different contaminants and their concentrations from various operations) a. Cooling Tower Blowdown:

Different effluents from fertilizer industry and their proposed treatment

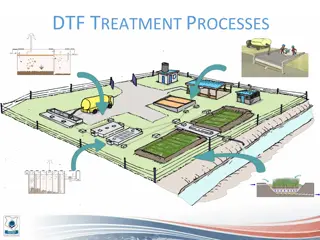

Treatment of effluents from fertilizer industry Physio-Chemical Processes: (a) Air Stripping: Ammonium ions (NH4+) in water exist as NH3 at high pH. The ammoniacal nitrogen in effluent can be removed by air stripping of ammonia from the effluent at an elevated pH, as at pH level > 7.0, ammonia is liberated as gas. This dissolved gaseous ammonia in the effluent is stripped off by blowing air through the effluent. Alkali is added to the waste to bring the pH to about 10 to 11 and then it is pumped to the top of cooling tower type packed tower, uniformly covering the full surface of the packing. The tower is either cross flow or counter flow with induced or forced air circulation The wastewater moves down through the packing counter-current with the air flow. Before the waste-water exits the bottom of the tower, the ammonia present in it, is stripped off. The factors to be considered while designing an air stripper for maximum removal of ammonia are pH, temperature, ammonia concentration (approximately 50mg/l), contact time with air and water- air-water ratio, etc.

(b) Steam Stripping: Ammonium ions (NH4+) in water exist as NH3 at high pH. Steam stripping of ammonia is adopted by the oke-oven industries for the recovery of by-product ammonia. The pH and the temperature are increased, to facilitate the formation of NH3. In a well designed distillation unit, the ammonia is usually stripped off by steam (with or without raising the pH as the case may be) and the ammonia is recovered by neutralizing it with sulphuric acid, followed by condensing it as dilute ammonia solution or as ammonium sulphate solution. Under ideal conditions, 90 to 99 percent ammonia removal efficiency is acheived.

Continued A cationic exchanger is used in which ammonium ion present in waste-water (mobile phase) is exchanged replacing the hydrogen ion present in the resin (stationary phase). The ion exchanger is regenerated by treating it with suitable concentration of sulphuric acid or nitric acid. The ammonium ion is regenerated as ammonium sulfate or ammonium nitrate and used for the production of fertilizer while the wastewater with very negligible amount of ammonia is discharged along with other effluents.

BIOLOGICAL PROCESSES (a) Biological Nitrification and Denitrification: Biological nitrification and denitrification very efficiently removes ammoniacal nitrogen from the effluents. This process is utilized in municipal waste treatment. ?????????? ???????? (???????) Nitrates Nitrification: This process employs the reaction of ammoniacal nitrogen with oxygen in aerated ponds or lagoons to form nitrites and finally to nitrates in the presence of nitrifying organisms. Factors affecting Nitrification include degree of aeration, water temperature, bacterial population, pH, initial ammoniacal nitrogen content etc. As alkalinity is decreased during the reaction, either the waste-water should be enough alkaline or some alkali must be added externally. Other bacterial nutrients such as phosphate, potassium, magnesium, iron, etc. also need to be added, if not present in adequate amount in the waste-water. This step is usually carried out in tank, pond, lagoon, trickling filter, etc. ??????? ?????? (?????????) ?2O + ??2 Ammoniacal Nitrogen

Continued . Denitrification: The nitrates so formed, are reacted in an anaerobic pond in the presence of biodegradable carbon compound to form nitrous oxide and carbon dioxide. As the denitrifying micobes utilize only organic carbon as the carbon source, a supplement of a readily biodegradable soluble organic compound needs to be added to the nitrified effluent before it enters the denitrification unit. The organic carbon usually employed is methanol (2 2.5g), a sewage effluent of organic waste from industries. The process of denitrification requires negligible dissolved oxygen in the effluent, neutral pH, adequate supply of organic carbon, accurate detention time etc.

Continued . (b) Algal Uptake: Algae extract ammoniacal Nitrogen from waste-water as food material to form cell tissue. Adequate carbon dioxide and some other nutrients are also needed. For fixing up 1 g of nitrogen into algal cell material, 10 to 12g of carbon (as carbon dioxide) is usually required. (c) Oxidation Pond: Oxidation ponds purify the wastewater through interaction between bacteria and algae. The bacteria decompose the biodegradable organic matter using dissolved oxygen and generate carbon dioxide, nitrates and phosphates. The nitrates and phosphates (formed by bacteria and also present as impurity in effluents) are consumed by algae as food material and carbon dioxide is used in the process of photosynthesis The ammoniacal nitrogen present in effluents can be efficiently removed by adjusting detention time, depth of the pond, concentration of algae, concentration of ammoniacal nitrogen, sunlight, etc.

Continued . (d) Urea and Nitrate Nitrogen: To remove urea efficiently from the effluents, thermal urea hydrolysis is usually done. Sometimes, hydrolyser stripper is employed to carry on hydrolysis. There is recovery of ammonia in this process. Some soil bacteria in the presence of organic carbon, hydrolyze the urea present in the effluents by secreting enzyme urease to form ammonia and carbon dioxide. ??2????2+ ?2? (??4)2??3 The value of pH rises during above process. About 90- 95 % of urea can be hydrolyzed in 24 hours, using this process.

Continued . (e) Suspended Solids: The suldge, ash slurry (from coal gasification plants, steam generation plants or phosphoric acid plant) are the usual suspended solids present in the effluents. Refer to the primary treatment of industrial effluents already covered before. (f) pH: If the effluents are highly acidic, lime or soda ash is added and if the effluent is alkaline, sulpnuric acid may be added. Proper mixing is very important for neutralization to occur. This is done by flash mixing or mixing by agitation or recirculation.

Continued . (g) Oils and Greases: Usually oils and greases,(present in effluents in non-emulsified form) float on the surface. Generally, gravity type mechanical oil separators are used. The oils and grease float on these separators and the depth of the tank is adjusted according to the quantity of oil present. The collected oil is skimmed by mechanical means periodically. Oil separators usually reduce the oil content < 50mg/L. If 2 to 10mg/L of oil content is to be attained, the effluent may be passed through active carbon or porous coke bed.

Continued . (h) Arsenic: Arsenic is used in absorbent liquids for carbon dioxide removal. And due to leakage in pump glands, flanges, joints, etc.,and from spillages, some arsenic enters the effluents. The waste-water having arsenic is filtered, concentrated, again filtered through active carbon filter. When filtration is not possible, the arsenical solution is evaporated to dryness and the solids are packed in concrete drums, sealed and buried underground or disposed off into the deep sea.

Continued.. (i) Chromate and Phosphate: To prevent the scaling and/or corrosion of cooling water employed during processing of fertilizers, different inhibitors are used. Various combinations of chromate, phosphate and zinc are generally used for this purpose. So, all these add as impurities in the effluents and need to be removed from the effluents. The basic principle involved in chromate removal is the reduction of hexavalent chromium into trivalent chromium followed by precipitation of chromium as chromium hydroxide

Continued .. The effluent containing chromate is collected in a tank and the pH of the water is adjusted to 2 to 4 by the addition of sulphuric acid. Than, ferrous sulphate, sodium sulphite, sodium meta bisulphite of sulphur dioxide is added to reduce hexavalent chromium. For removal of 1g of CrO4,about 10 g of ferrous sulphate, 2.5 g of sodium sulphite or 1.5 g of sulphur dioxide is added. After reduction, pH is increased by adding lime when,chromium precipitates out.

Continued .. Reactions: Reduction of Chromate: 1. When ferrous sulphate is used for reduction: Na2Cr2O7+ 6FeSO4+ 7H2SO4 Cr2(SO4)3+ 3Fe2(SO4)3+ 7H2O + Na2SO4 2. When sulphur used for reduction: Na2Cr2O7+ 3Na2SO3+ 4H2SO4 4Na2SO4+ Cr2(SO4)3+ 4H2O 3. When sulphur dioxide is used for reduction: Na2Cr2O7+ 3SO2+ H2SO4 Cr2(SO4)3+ H2O + Na2SO4 Precipitation with Lime: Cr(SO4)3+ 3Ca(OH)2 2Cr(OH)3+ 3CaSO4 Fe2(SO4)3+ 3Ca(OH)2 2Fe(OH)3+ 3CaSO4 Lime treatment also partially precipitates out phosphate which is added to the cooling towers as sodium hexametaphosphate. Recently, process based on electrolysis using iron electrode, involving reduction with ferrous ion, has been developed. This process occurs at pH 6-8. The chromium hydroxide and iron hydroxide are precipitated together and separated as a sludge by clarification.

Continued .. The boiler stack contains around 0.2 percent SO2which is a reducing agent, which enters the effluents as furnace oils have about 4% of Sulphur. Cr2O4- + 3SO2+ 2H+ 2Cr+3+ 3SO4-2 + H2O Above reaction occurs at pH 2 to 3. The SO3present facilitates to attain this pH and SO2 at this pH easily reduce the hexavalent chromium. Trivalent chromium as chromium sulphate is less toxic. So, soluble chromium sulphate is converted into chromium hydroxide at pH 10 to 11 by the adding alkali.

References Environmental Chemistry by G.S Sodhi Environmental Chemistry by Stanley E. Manahan Internet Sources http://www.engineeeringenotes.com/environmental- engineering/treatment-of-effluents/treatment-of-effluents-of- fertilizer-industry-environmental-engineering/16995

THANK YOU Ritu Malik Assistant Professor Rajdhani College University of Delhi