Electric Power Steering Assembly Line Enhancements

This content discusses the virtual manufacturing proof of concept for an Electric Power Steering (EPS) assembly line, focusing on analyzing current processes, enhancing line efficiency, and ergonomic studies. The article covers solutions, suggestions for improvements, and benefits to customers.

Download Presentation

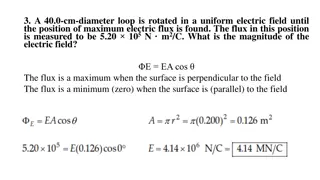

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Electric Power Steering (EPS) Assembly Line Virtual Manufacturing POC Customer Details ZF Friedrichshafen AG, Germany is the major Tier-1 Supplier to major automotive OEMs like BMW, Mercedes-Benz, Porsche Ford, GM & Fiat etc., across the globe. ZF is main Customer to SATVEN in Product Design (CAD/CAE) for last 20 Years, (India as well as in Europe, NA and APAC regions). Scope of Work Analyze the current Manufacturing processes and enhancement in the Assembly line in terms of Process, Cycle Time & Line Efficiency. To carryout operator ergonomic study for the assembly process Satyam Venture Engineering Services 1

Electric Power Steering (EPS) Assembly Line Virtual Manufacturing POC Our Solution o Current EPS Assembly Line 3D Layout developed and each Assembly line (Pre-Line, Main-Line & Testing- Line) Processes simulated. o Identified and areas of issues and accordingly updated fixtures, Processes and Human related activities o Ergonomic study out identified the areas of improvement Main Line Test Line Pre-Line Satyam Venture Engineering Services 2

Electric Power Steering (EPS) Assembly Line Virtual Manufacturing POC Suggestion / Enhancements o Conveyor can be used to transfer Pinion HSG from OP35A to OP35B. Housing is transferred manually from one station to other. By installing conveyor, both these stations can be included in the pre-line for continuous production & operator fatigue is reduced. o By rotating EPP loading fixture by 90 , Space between the fixtures has been increased which gave more comfort for the operator to perform task. o Fixture modification: Clamp in the fixture can be modified such that loading / unloading of parts will not have interference with it when it is in open position. These type of modifications can be implemented in the complete assembly line for collision free environment Satyam Venture Engineering Services 3

Electric Power Steering (EPS) Assembly Line Virtual Manufacturing POC Benefits Customer is able to visualize the Assembly Line Virtually before implementing on the shop floor for the layout Enhancements as below: Introduction of material handling equipment from Pre-Line to Main-Line (Manipulator) o Optimizing cycle time & assembly line balancing 18 ~20% o Reduction in rejections as the processes are Automated (7 in Pre-Line & 5 in Main-Line stations) o Improved process to have ease of visibility & accessibility for an operator to perform tasks & prevent Musculoskeletal Disorders (MSDs), less operator Fatigue. Customer Testimonial from ZF Germany & NA on ZF - EPS POC We are very much impressed with the POC presentation and we would like to implement Digital Manufacturing related activities in our European plants. Satyam Venture Engineering Services 4