Electrode Production for Small FTM Detector

In this project, electrodes are being produced for the small FTM detector for demonstrating the FTM principle and optimizing time resolution. The design involves creating a prototype with isolated low noise layers and specific electrode configurations. Mechanical designs for internal foil holders and external/internal holders are being developed. Additionally, detailed specifications for disks to be produced by EP-DT-EF-MPT Workshop are outlined. The detection concept includes single detection layers and plans to scale up to multiple layers based on initial testing results. Conversion of design files from DXF to GERBER format is required for manufacturing.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Production of Electrodes for the small FTM Piet Verwilligen INFN Bari 18-06-2019

Reminder Reminder: Design of the small FTM : Design of the small FTM Main Idea: - well isolated low noise detector to demonstrate the FTM principle: time resolution vs number of layers - Make small area prototype, with only 2 electrodes: top & bottom - Go back as much as possible to the design of the original prototype (with resistive kapton XC)

Disks to be Disks to be produced produced by EP by EP- -DT DT- -EF EF- -MPT Workshop MPT Workshop DLC Coated (USTC) 50um thick Polyimide rdisk = 19 mm Both disks: rdisk = 19 mm Cu electrode with tongue r1=16mm, r2=18mm Yellow: active (holes) ractive = 10 mm Orange: plain DLC Amplification foil (2x) DLC covered Polyimide (50um) Active Area: ractive = 10 mm 50um holes at 140um pitch Top hole diam: 50um, bottom hole diam: 70um Cu ring (5um thick) r1=16 mm, r2=18mm Resistive Kapton XC Drift foil (4x) Resistive Kapton XC (25um)

Disks to be Disks to be produced produced by EP by EP- -DT DT- -EF EF- -MPT Workshop MPT Workshop 50um thick Polyimide rdisk = 19 mm Both disks: rdisk = 19 mm Cu (readout) 5um ractive = 10 mm with central via to solder wire Readout foil Plain 50um polyimide foil Central Cu disk (ractive = 10 mm) Central via that allows to solder wire at the bottom side of the readout foil Insulation foil Mylar As thin as reasonably possible: 5-10um Mylar (5-10um)

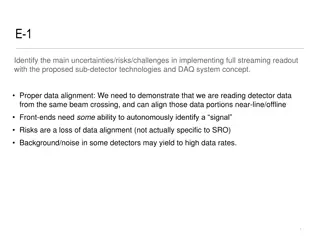

Detection Detection Concept Concept: Single : Single detection detection layer layer of FTM of FTM Outline of a Single Detection layer for the small FTM I want to make the detector with 2 layers of 5mm drift Spacers made by INFN-Bari Important to have via on top and bottom Readout foil If signal can be picked-up and discriminated then I will go to 4 layers of 2.5mm; 8 layers of 1mm; I would like to order: 2 x Readout foil 4 x Drift foil 2 x Amplification foil 2 x thin Mylar disk Design is very simple, DXF available, need conversion to GERBER Signal Wire (to SMA) Top Readout (PI) Mylar Isolation (thin) Drift Electrode (XC) Gas Gap (5mm) Amp Electr (DLC + PI) Bottom Electrode (XC) Mylar Isolation (thin) Bottom Readout (PI) Signal Wire (to SMA)