Emulsion Specification and Comparison Analysis in Construction Industry

Understanding the importance of specifications in utilizing scrub seal effectively, and exploring the components, challenges, and comparisons with conventional chip seal emulsions. Key topics include subcommittee membership, material components, the reasoning behind specification adjustments, evaluation methods, and motivation for adopting new testing techniques.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Scrub Seal Update Scrub Seal Update Andrew Hanz Mathy Construction Emulsion Task Force Meeting Indianapolis, IN June 21, 2018

Subcommittee Membership Codrin Daranga Andy Clayton Hussain Bahia Ken Gryzbowski Jeff Schoger Kevin Carlson Katy Fleury

Why have a specification? Scrub seal is being used effectively throughout the US. All based on proprietary specifications. Universal specification o Reduces confusion o Promotes competition o Promotes innovation

Components of the Materials Spec Polymer Modified Rejuvenating Emulsion o Emulsion o Emulsion Residue o Rejuvenating Agent o Polymer Aggregate o Gradation o Quality Requirements

Why was the spec. pulled back? Emulsion Residue Properties Emulsion Residue Properties Polymer Identification Polymer Identification Original Proposed test was MSCR %R, 3.2kPa at 10C >55%. 1. Elastomeric Systems Test could not differentiate between PMAs and CRS-2. Test temperature too low and material too stiff. Solution: MSCR at 52 C and 0.1kPa 2. Non-Elastomeric Systems MSCR or other elasticity test does not identify polymer presence. Solution: TBD

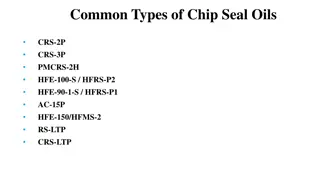

Scrub Seal vs Conventional Chip Seal Emulsions Scrub Seal vs Conventional Chip Seal Emulsions MSCR DSR at 52 C %R 0.1 %R 3.2 Emulsion G*/sind delta 10 52 58 10 52 58 CMS-2P 2.86 77 75.5% 29.9% 19.4% 68.3% 8.7% 3.0% CRS-2 3.228 85.3 63.0% 4.2% -0.4% 61.1% 0.8% 0.0% CRS-2P 4.494 74.4 77.7% 48.7% 47.7% 69.8% 26.8% 14.0% HFRS-2 5.13 76.8 79.5% 61.8% 53.9% 72.3% 10.5% 3.4% HFRS-2P 5.228 66.8 86.4% 83.0% 80.7% 78.4% 59.7% 35.0%

Emulsion Specification Table - Elastomeric PMREa Grade Min Max Tests on residue from distillationd: Penetration, 4 C (39 F), 200 g, 60 s, 0.1 mm 40 Or G* at 4 C 10 rad/s, 1% strain at Elastic Recovery, 25C T301 OR MSCR Percent Recovery at 0.1 kPa, 52 C (50 F), % Ash Content, % Viscosity, 60 C (140 F), Pa S Or Jnr at 52 C TBD 50? 20 1 500 4.5?? D Residue preparation for testing may use the alternate methods, R 78, ASTM D7403, or ASTM D7944, so as not to negatively affect the properties of any polymer modifiers contained therein

Motivation for Changes Allow Old and New Test Methods o Old: Penetration, viscosity, elastic recovery o New: All DSR based Why? Testing Time and Effort o All residue approval tests could be conducted on one machine. o Use of moisture balance significantly reduces time.

Next Steps All scrub seal emulsions o Evaluate demulsibility requirements. Considering removing from specification or a very high maximum (i.e. 80%) Elastomeric Systems o Distribute data table and solicit test results using Old and New approaches. Non-elastomeric Systems o Evaluate NCHRP 9-50 approach for polymer identification.