Enhancing Biogas Yield Through Post-Treatment of Residual Sludge

This report discusses the feasibility and benefits of increasing biogas yield through post-treatment of residual sludge. The study includes a detailed analysis of the process, findings from digestion tests, and conclusions drawn indicating a significant boost in biogas production. The post-treatment involves hydrothermal carbonization and recirculation of process water, showcasing improved methane yield, digestate mass, and overall gas yield. The study also highlights additional advantages such as better phosphorus concentration, reduced ammonia levels, accumulation of heavy metals in hydrochar, and side benefits like hygienization and easy dewatering. The research findings provide valuable insights into enhancing biogas production efficiency.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Increased yield of biogas by post treatment of residual sludge Energiforsk report 2016:312 Programkonferens Energigasteknik, G teborg 8/9 juni 2017.

INCREASED YIELD OF BIOGAS BY POST TREATMENT OF RESIDUAL SLUDGE REPORT 2016:312 Energy Gas Technology Programkonferens Energigasteknik, G teborg 8/9 juni 2017.

Feasibilty study on hydrothermal treatment of residual sludge and increased yield of biogas. Project duration 6 months. Final report October 2016. Funding: Samverkansprogram Energigasteknik Swedish Energy Agency and Swedish Energy Research Center Energiforsk. Partners: Biokol Sverige AB K ppala f rbundet, Liding . G strike Vatten AB. Tekniska verken i Link ping AB. R&D partner: Leibniz-Institut f r Agrartechnik und Bio konomie (ATB), Potsdam Programkonferens Energigasteknik, G teborg 8/9 juni 2017.

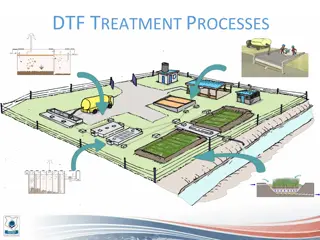

Model of material flow: Biogas digester => HTC =>Biogas digester => Exit Programkonferens Energigasteknik, G teborg 8/9 juni 2017

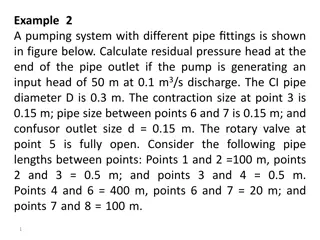

Result of digestion tests. Specific CH4yield related to VS, Volative Solids, content for sewage sludge, two process waters and mixture in ratio 1:5 of sludge and process waters. SS: Sewage sludge, PW1: HTC process water; screw press, filter towel, pore size 100 micrometer PW2: HTC process water; vacuum filtred, filter paper, pore size 12 micrometer Programkonferens Energigasteknik, G teborg 8/9 juni 2017.

Set up: Effluent from aneorbic digester is concentrated to 10% DS and hydrothermal carbonized (HTC). HTC slurry is separated into hydrochar and process water. HTC process water is added to digistate precursor sludge by ratio 1:5. Summary of the findings in the study: a) Methane yield + 31% => Digestate mass +20% plus increased gas yield +11%. b) Thermal energy for HTC well covered by increased amount of gas. c) Phosporous in precursor sludge is concentrated in the hydrochar. d) Ammonia concentration after dilution 5 times is well below critical limit. e) Heavy metals are accumulated in the hydrochar. f) Side benefits: Hygenization and easy dewatering. Conclusion: It s possible to achieve significant more biogas by hydrothermal treatment of the residues and recirculation of process water. Programkonferens Energigasteknik, G teborg 8/9 juni 2017.

Acknowledgements: Reference group: Mats Linder and Hans Simonsson, G strike vatten AB, G vle. Jan Moestedt Tekniska verken i Link ping AB. Devisa Karat, K ppalaf rbundet Liding : Laboratory work: Benjamin Wirth and Maja Werner, ATB: HTC and aneorobic testing. Ignasi Puigdomenech: equilibrium calculations. Agnieszka Witkiewicz, K ppalaf rbundet: Aneorobic testing. Project leader: Eva Bj rkman, Biokol Sverige AB. Programkonferens Energigasteknik, G teborg 8/9 juni 2017.