Erosion Corrosion in Materials Engineering

Erosion corrosion is the deterioration of metals and alloys due to relative movement between the surface and corrosive fluids. It is characterized by grooves and surface patterns with directionality. This type of corrosion can affect a wide range of equipment exposed to fluids, such as piping systems, turbines, valves, and more. Different types of corrosive media, including gases, aqueous solutions, and liquid metals, can contribute to erosion corrosion. The appearance of erosion corrosion includes grooves, gullies, and rounded holes, often showing a directional pattern. Surface films like passive films on stainless steel play a crucial role in protecting metals from corrosion. The mechanism of erosion corrosion is complex and involves factors like turbulent flow and the development of protective layers on the metal surface.

Uploaded on Feb 18, 2025 | 1 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Mustansiriyah University Materials Engineering Dr. Lubna Ghalib

Erosion Corrosion: Erosion corrosion is the deterioration of metals and alloys due to relative movement between surface and corrosive fluids. Depending on the rate of this movement, abrasion take place. This type of corrosion is characterized by grooves and surface patterns having directionality. Remember the distinction between erosion corrosion and erosion: Erosion is the straightforward wearing away by the mechanical abrasion caused by suspended particles. e.g., sand-blasting, erosion of turbine blades by droplets. Erosion-corrosion also involves a corrosive environment the metal undergoes a chemical reaction. Corrosive Medias Many types of corrosive media could cause erosion corrosion. Gases, aqueous solutions, organic systems & liquid metals are some common corrosive medias that causes this type of corrosion

Erosion Corrosion: Examples - Many metals & alloys susceptible to erosion corrosion e.g. aluminum, lead, stainless steels, carbon steels - All types of equipment exposed to fluid are susceptible to this type of corrosion such e.g. piping systems, elbows, tees, valves, pumps, blowers. - Also centrifuges, propellers, impellers, agitators, heat exchangers tubing - Measuring devices like orifices, turbine blades, ducts & all those equipment which are some way or the other exposed to fluids.

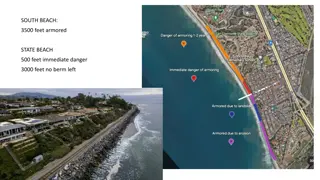

Erosion Corrosion: Appearance It appears in the form of grooves, gullies, waves, rounded holes & valleys. They typically show a directional pattern. This is figure showing erosion corrosion of condenser tube wall by water flow. Vulnerable equipment is that subjected to high-velocity fluid, to rapid change in direction of fluid, to excessive turbulence. viz equipment in which the contacting fluid has a very thin boundary layer. Erosion-corrosion of condenser tube wall.

Erosion Corrosion: Surface Films: These are specially developed layers on the surface of metals which can protect the metal. Such films develop due to the action of different environment on metals e.g. Al2O3 film developed on Al metal protect it from corrosion. There are two types of such films: 1. Relatively thick porous diffusion barriers, formed on carbon steel (red rust) & copper (cuprous oxide). Diffusion barrier is formed by ionic dissolution followed by precipitation. It is more easily damaged & can be corroded. 2. The thin invisible passive film on SS, Ni & Ti etc. Passive films are formed by direct oxidation & can withstand much more sever conditions.

Erosion Corrosion: Mechanism Exact mechanism of erosion corrosion is less understood but it is believed it occurs due to: 1. Turbulent flow: Turbulent flow is one of the major causes behind the occurrence of erosion corrosion. It results in more contact between metal &. fluid. It is mostly confined to few inches at tubing inlet.

Erosion Corrosion: 2. Impact of suspended solid particles: Solid particles entrained in liquid flow damage both types of surface films explained above. Such particles can erode the metal as well & contribute to metal loss. This happens due to high impact of solid particles on the object through which fluid is passing. 3. Liquid droplets in gas flow: Liquid droplet can cause erosion corrosion due to exposure of solid to repeated impact by droplets. It generates impulsive & destructive contact pressure. It is a problem with low pressure turbines & also rain erosion of aircrafts. 4. Impact of gas bubbles in aqueous flow: Erosion corrosion of copper alloy heat exchanger is due to local damage of film by air bubbles. Nitrogen bubbles can also do the same damage.

Erosion Corrosion: Factors affecting on Erosion Corrosion: 1. Effect of flow velocity 2. Galvanic Effect 3. Nature of metal & Alloy Prevention of Erosion-Corrosion Methods are used to prevent erosion corrosion. 1. Design 2. Alteration of Environment 3. Coatings 4. Cathodic Protection 5. Better material

Erosion Corrosion: CAVITATION DAMAGE : is particular form of erosion caused by the "implosion" of gas bubbles on a metal surface. It is often associated with sudden variations in pressure related to the hydrodynamic parameters of the fluid. Similar effect to Erosion corrosion mechanical removal of oxide film caused by collapsing vapor bubbles

Erosion Corrosion: CAVITATION DAMAGE Examples

Erosion Corrosion: FRETTING CORROSION Fretting is a phenomenon of wear which occurs between two mating surfaces subjected to cyclic relative motion of extremely small amplitude of vibrations. Fretting appears as pits or grooves surrounded by corrosion products. Fretting corrosion occurs in bolted parts, engine components and other machineries. Similar to Erosion corrosion but surface mechanical action provided by wear of another surface generally alternating