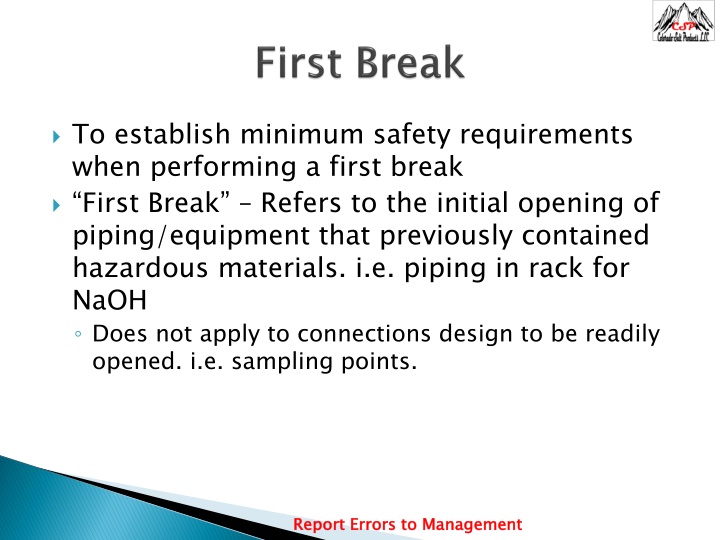

Establishing Minimum Safety Requirements for First Break

When performing a first break on piping/equipment that previously contained hazardous materials, it is crucial to follow safety protocols to avoid incidents. This presentation covers the steps involved in performing a first break, including obtaining permits, responsibilities of permit issuers and workers, system shutdown, and pressure release procedures. It emphasizes the importance of selecting safe locations, recognizing potential dangers, isolating lines, and following proper bolt loosening procedures to ensure safety.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

To establish minimum safety requirements when performing a first break First Break Refers to the initial opening of piping/equipment that previously contained hazardous materials. i.e. piping in rack for NaOH Does not apply to connections design to be readily opened. i.e. sampling points. Report Errors to Management Report Errors to Management

This presentation covers pipes lines- and equipment opening (LEO) Pipes and equipment may contain: Corrosives (bleach, caustic, acid) Toxic (chlorine gas) Flammable (propane) Cold Fluid(Liquid N2) High Pressure(Compressed Air) Inert Gases(nitrogen) Report Errors to Management Report Errors to Management

A permit is required when opening any pipe Different responsibilities fall on the Permit Issuer and the Person Conducting Work Permit Issuer: Facility manager or designee Assist with line identification, shutdown, isolation, purging etc. Completes LEO permit Finishes paperwork after work completed Report Errors to Management Report Errors to Management

Person Conducting Work: Responsible for Identifying the correct line Obtaining/signing LEO before starting work Obtaining proper PPE Verify line is drained before working Comply with LEO requirements Finishes paperwork after work completed Report Errors to Management Report Errors to Management

Worker Reports to equipment owner Explain Work Obtains LEO Proper PPE is obtained and safety showers/ fire extinguishers checked Equipment owner shuts- down the system The system is isolated: must meet lockout/tag-out requirements, may sometimes need blinding Pressure Release: Pressure is bled off in a safe manner Line is drained/purged/cleaned Report Errors to Management Report Errors to Management

1) Pick the safest location 2) Approach anything as potentially dangerous 3) Ensure line is isolated 4) Loosen farthest bolts first Report Errors to Management Report Errors to Management

Duration: Only lasts as long as the users work shift Retention: Must be kept for a year Report Errors to Management Report Errors to Management

Purpose To ensure that personnel, the environment, and equipment are protected from unintended releases of potentially hazardous substances or energy while performing process equipment and piping repair, service or maintenance activities. Purpose Report Errors to Management Report Errors to Management

In general, pipes contain substances that could be hazards or at high pressure, or hot, so careful attention should be given while trying to break any line or to enter into any confined space. All pipes must be disconnected, blanked or blinded off before any Personnel enter the confined space. Report Errors to Management Report Errors to Management

THE CLOSING OF ISOLATION VALVES ON ANY LINE CONTAINING A HAZARDOUS SUBSTANCE IS NOT ACCEPTABLE AS A SUBSTITUTE FOR BLANKING OR BLINDING. Report Errors to Management Report Errors to Management

Lines which have been blanked or blinded shall be clearly marked with a tag to indicate that a blind or blank has been installed. A record of the blinding must be entered in the Blind Placement Log Book by the operator in charge when the blinding procedure occurred. Report Errors to Management Report Errors to Management

Report Errors to Management Report Errors to Management

Spectacle Blind with blind side installed Report Errors to Management Report Errors to Management

Blind Flange installed Report Errors to Management Report Errors to Management

Slip Blind installed Report Errors to Management Report Errors to Management

Blanks or blinds shall be thick enough to hold the pressure of the line, proper material and installed in a manner to provide adequate safety for the particular conditions of anticipated maximum pressure, temperature, and work to be completed. Report Errors to Management Report Errors to Management

Where it is impractical to blank or blind piping containing hazardous substances, written work procedures must be developed and approved by the Facility Manager and the Safety Committee to ensure at least equal protection to all personnel exposed to the potential hazard. Report Errors to Management Report Errors to Management

On welded joint piping, valves will be acceptable to blanking or blinding providing that: Block valves in the flow line are LOCKED out in a CLOSED position. A bleed-off valve and line is located between the closed block valve and the confined space. This bleed-off valve is LOCKED in the OPEN position. A worker is stationed at the bleed-off location to monitor and to warn others if an emergency occurs. There is NO other way to blind the line. Report Errors to Management Report Errors to Management

Welded joint blinding Report Errors to Management Report Errors to Management

Responsibilities Person in Charge, Lead Operators and Consultants Must evaluate the process to be isolated with all affected personnel to ensure that all process systems and piping are properly isolated and identified. Responsibilities Report Errors to Management Report Errors to Management