Experimental Setup and Safety Analysis

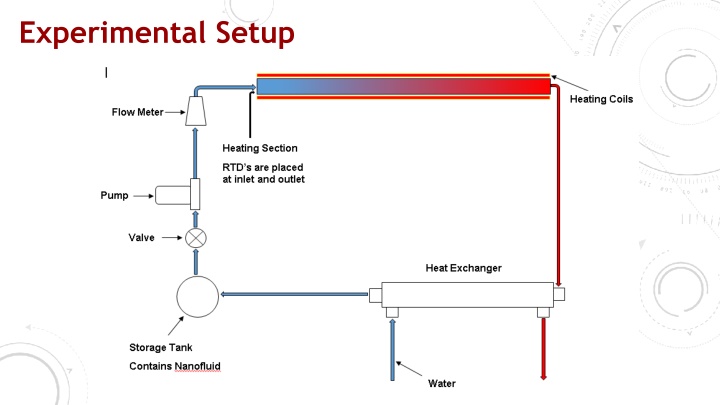

In this project, the experimental setup for a nanofluid system is detailed, along with manufacturing processes, assembly, design, and validation. The safety analysis covers potential failure modes and risk assessments. Test protocols and procedures are outlined for preliminary testing and final validation before market launch.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

46/64 Final Design (39inx21.906inx.5in) Pump Reservoir RTD RTD

51/64 Manufacturability Manufacturing Process Ordering Supplies Pump Copper pipes Thermocouples Flowmeter Valves,etc. Inspection Machining Lathing Possible Milling Threading Welding Further Inspection/Testing Cleaning/ Packaging

52/64 Manufacturability: Assembly Process: Pipelining Copper piping Elbows Heating tape Concentric Pipes (Heat Exchanger) & diameter pipes Reducers Reservoir 2ft. x 3ft. nanofluid accumulator Miscellaneous(extra materials needed) Thermocouples or RTDs Flowmeter

53/64 Manufacturability: Design for Manufacturing: Material Copper Design form Circular piping 9 x6 rectangular frame Pipe connection Threading Welded

54/64 Preliminary Test Protocols 1. Run system for 10-15 minutes with no particles. 1. Check if unit is in proper position. 1. Check for proper functioning Pump Flowmeter Heating tape Reservoir overflow Thermocouples No leakage in the system 4. Run system with only water for an entire day. 4. Reinspect system for damages during test run. 4. Further inspect the entire system, for signs of failure: Pump wear Pipe leakage Measurement system failure.

55/64 Test Protocols Procedures 1. Fill the reservoir with nanofluid. 1. Turn on heating tape and allow it to reach steady state. 1. Start pump, and allow the system to run. 1. Take data on the second cycle and check to see if it makes sense. 1. If so, test with Different nanoparticles sizes Various temperatures 6. Record data. 6. Item is ready to shipped out into the market and business.

57/64 Safety Analysis Design and failure modes: 1. Nanofluid-pump wear 2. Improper welding 3. Pump malfunction 4. Reservoir leakage 5. Tolerance Pipe diameter

58/64 Safety Analysis DFMEA Rank Factor Failure Mode Label Severity Frequency Easily Found Nano fluid pump wear FM1 4 5 2 40 Improper Welding FM2 3 3 5 45 Pump malfunction FM3 5 1 5 25 Reservoir Leakage FM4 5 1 4 20 FM4 5 1 Tolerance 1 5 Total 135