Fabrication Processes for White Wares Production

Several techniques like slip casting, plastic shaping, and pressing are used in the manufacturing of white wares, with the method chosen based on factors like shape complexity and required properties. Slip casting, a common process, involves creating a clay-based slip that is poured into a porous mold to form the desired product, which is then dried and sintered. This process is crucial for producing items like sanitary ware, ceramic vases, and art objects.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

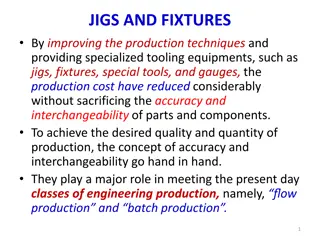

Fabrication processes : Several techniques are employed to produce the component shape in the green (unfired) state. The three major fabrication processes used in the manufactures of white wares are :Slip casting , plastic shaping and pressing .The method chosen for any particular product depending on: -Complexity of shape. -Size variation which can be tolerated. -Properties of the body and properties required in the produce . ** Green: is a ceramic before it is fired. Brown, white, or gray potter's clays are well known green ceramics.

Slip Casting: Slip casting is the most common process. It can be used to produce either hollow or solid ware . A slip is a suspension of clay-based materials in water, prepared by wet ball milling the ingredients .The slip is poured in a porous mould (made of plaster of Paris), the water is absorbed by the mould, leaving behind a solid layer on the mould wall the thickness of which depends on the time .The process may continue until the entire mould cavity becomes solid (solid casting), or draining the remaining slip when a solid of sufficient thickness is formed (hollow casting) .As the casting dries and shrinks, it will pull away from the mould wall so that the green product is removed easily.

The formed ware are then dried and sintered to obtain the finished product .The nature of the slip (high sp. gravity, high fluidity) and the mould (porosity, moisture content) are extremely important .Common products formed in this way include: sanitary ware, ceramic vases, art objects.