Fall Protection Strategies for Safer Working Heights

The essential fall protection strategies and control measures required in construction to ensure worker safety when working at heights. Learn about hazards, employee training protocols, and effective control measures to prevent falls and injuries.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Fall Protection Construction

Learning Objectives Gain knowledge and skills needed for fall hazards Plan and work safely when hazards are present

Overview Fall Protection Strategies Agenda Equipment for Fall Arrest Systems Responsibilities

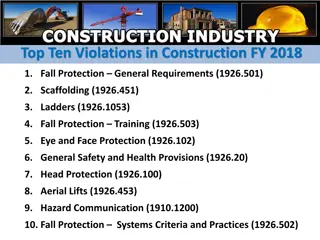

Hazards of Working Heights Frequently cited OSHA provisions are failure to: Protect workers from falls of 6 feet or more Protect workers from falling into floor openings Provide guardrails

Hazards of Working Heights Hazards causing most fall-related injuries: Unprotected sides, wall openings, and floor holes Improper scaffold construction Unguarded protruding steel rebar Misuse of portable ladders

Employee Training Training is required in the following areas: The nature of fall hazards Correct procedures for fall protection systems Use and operation of protection devices Roles in safety monitoring and fall protection plan Limitation of equipment

Employee Training Refresher training is required if there are: Changes in the workplace Changes in the types of fall protection systems Inadequacies in an affected employee's knowledge

Control Measures Control measures used to for serious hazards: Perform work at ground level Restrain worker so they can not reach the edge Use aerial lifts Use control line and personal fall arrest systems Cover holes as they are created

Fall Protection Strategies

Fall Protection Strategies Guardrails Safety nets Personal fall arrest systems Warning lines Controlled access zones Safety monitoring Covers Fall protection plans Fall Protection Strategies include:

Guardrails A barrier to prevent employee falls to lower levels: Specific requirements: Height of top rails shall be 42 inches plus or minus 3 inches above walking or working level Withstand force of at least 200 pounds

Safety Net Safety nets must have: Border rope for webbing Minimum breaking strength of 5,000 pounds Installations must be tested: After initial installation or major repair Before being used Whenever relocated At 6-month intervals if left in one place Inspected for deterioration at least once weekly

Personal Fall Arrest System Stops employee falls from working levels Limit maximum arresting force to 1,800 lbs. Be rigged Complete stop and limit maximum deceleration Strength to withstand twice the potential impact energy

Warning Line System Roof barrier warning of side or edge Warning lines shall consist of: Ropes Wires Chains Supporting stanchions

Controlled Access Zones Controlled access zone is permitted only in: Overhand brick laying and related work Fall Protection Plan for leading edge work Controlled access zone should be as follows: Consist of ropes, wires, tapes, or equivalent and supporting stanchions Flagged Rigged and supported Minimum breaking strength of 200 pounds

Safety Monitoring Safety monitoring permitted when: Employees are engaged in low slope roofing work Workers are covered by written fall protection plan Employer designated competent person must: Be able to recognize hazards Monitor working or walking surfaces Visual sight and communication Can not be distracted duties

Covers Covers protect employees from falls through holes: Holes covered Sites surveyed before working Continually audit as work continues Support two times the weight of employees

Safety Monitoring Written fall protection plan must state: Why conventional fall protection systems cannot be used where the fall hazard is present Measures taken to reduce or eliminate fall hazard where conventional fall protection systems cannot be used An example fall protection plan is provided in the OSHA fall protection standard

Personal Fall Arrest Equipment

Equipment Use, Care, & Maintenance Equipment used: Body harness Vertical lifeline Horizontal lifeline Webbing Connectors Anchorages

Body Harness Body harnesses are designed to: Minimize stress forces Provides freedom of movement Minimize force on the body in falls

Vertical Lifeline Vertical lifeline must have: Strength of 5,000 lbs. or more Protected from being cut or abraded Separate vertical lifeline for each employee Self-retracting vertical lifelines have minimum strength of 3,000 lbs

Horizontal Lifeline Designed, installed, and used under supervision Complete personal fall arrest system

Webbing Ropes and straps used in: Body harness strength component Made from synthetic fibers Lifelines Lanyards

Connectors Made of drop-forged, pressed or formed steel, or equivalent material: Rings and Snap hooks Minimum tensile strength of 5,000 lbs Unless designed for it, do not engage to: Webbing, rope, or wire Each other D-ring Horizontal lifeline Incompatibly shaped object

Anchorages Used in attachment of personal fall arrest equipment: Must be independent of anchorage Supports at least 5,000 lbs

Responsibilities Recognize fall hazards in the workplace Utilize fall protection strategies Use personal fall arrest systems equipment