Feasibility Study for Radio-Pure Feedback Device in Integrated CSP

Explore the feasibility study for a radio-pure feedback device in integrated CSP to address excess noise issues caused by distributed capacitive coupling. The study proposes a solution involving selective etching of the silicon substrate and details the process, considerations, and prototype status.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

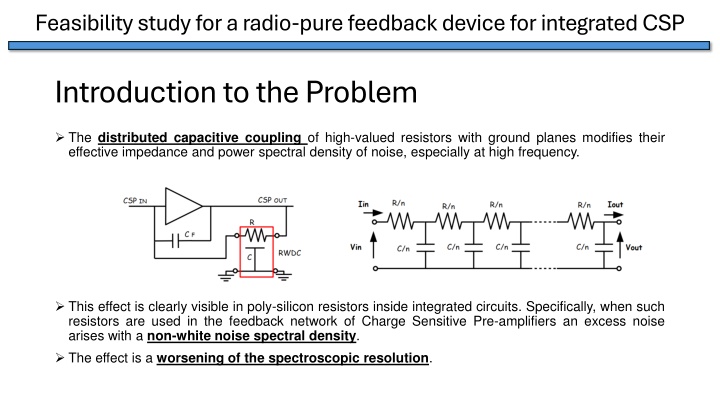

Feasibilitystudy for a radio-pure feedback device for integratedCSP Introduction to the Problem The distributed capacitive coupling of high-valued resistors with ground planes modifies their effective impedance and power spectral density of noise, especially at high frequency. This effect is clearly visible in poly-silicon resistors inside integrated circuits. Specifically, when such resistors are used in the feedback network of Charge Sensitive Pre-amplifiers an excess noise arises with a non-white noise spectral density. The effect is a worsening of the spectroscopic resolution.

Feasibility study for a radio-pure feedback device for integrated CSP A possible solution to the Problem Silicon substrate is radio-pure > good base for a rework. To overcome the issues given by distributed capacitive coupling, the substrate under the resistor must be removed: selective etching. Etching direction Typical substances used for this purpose: alkaline hydroxides (KOH, NaOH) ETP (Ethyline Diamine Pyrocatchecol dangerous, better not to use) TMAH (Tetramethyl Ammonium Hydroxide NH4OH)

Feasibility study for a radio-pure feedback device for integrated CSP Some considerations The action of NaOH is extremely slow due to the presence of silicon oxide on the substrate, which forms a protective layer. A two-steps process is mandatory: HF (hydrofluoric acid) to etch the external oxide layer NaOH to etch the polysilicon substrate During the process only the part to be removed must be exposed: the remaining ASIC must be protected with an appropriate mask (Kapton, resin) to avoid chemical attack. Technique used in the context of MEMS production Experimental Setup To handle the integrated circuit, a specific PCB (Printed Circuit Board) has been designed. It is made of rogers which is resistant to HF and NaOH. The circuit is glued onto the board which is also drilled to allow chemical attacks. After The HF fast attack, the system is placed inside a specifically-designed resin tank where the substrate area to be removed is continuously exposed to the NaOH solution. The NaOH solution, separately heated to increase its etching-rate, recirculates inside the tank by means of a peristaltic pump.

Feasibility study for a radio-pure feedback device for integrated CSP Status Prototype ASIC with high-valued resistor: designed, produced, ready in-house Chemical reagents: selected, bought, ready in-house Peristaltic pumps: selected, bought, ready in-house Etching pool with custom ASIC support: designed, to be 3D printed First etching results expected by end of 2024 Manpower for 2025 Stefano Capra 0.2 FTE Alberto Pullia 0.2 FTE + 1 bachelor thesis student before end of 2024 Funds request for 2025 2.0k consumables 2.0k travels to partecipate to collaboration workshops