Formula SAE Suspension Prototype Challenges and Solutions

Explore the design process of a Formula SAE suspension prototype, including the challenges faced, solutions implemented, and collaboration among team members for successful execution. Follow the journey of assembling jigs, addressing alignment issues, and planning for design iterations. Discover how the team overcame obstacles in welding and positioning the A-arms, leading to valuable insights and improvements for the prototype.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

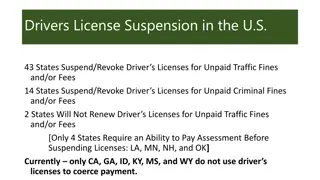

Formula SAE Suspension Prototype 2 Parker Johnson: Suspension Design Lead Chris Laney: Brakes Engineer Garrett Pearson: A-Arm Engineer Mathew Cusson: Steering Engineer Joseph Ciao: Pushrod Assembly Engineer Page 1

What is the question we are trying to answer? Will the jigs properly support the a-arms for welding, maintaining the proper position to keep the precise angles and allow for strong welds. Page 2

Methods/Manufacturing Process Jigs were assembled with wood and screws. The calculated angles were draw on to the board. For each of the 4 jigs. Blocks were placed to hold the arms is place, having members of the team hold the blocks tightly together as another person drilled them into place PHOTO Page 3

What was the answer? The jig does keep the arms firmly in place, but the team observed the a-arms are too low and do not properly connect to the joint. PHOTO Page 4

How did the answer inform the design? How do you plan to iterate? PHOTO We found that the depth of the jig where are arms are mounted does not line up properly and we will add additional spacers to raise the rods up to get the proper attachment point. Page 5

What did each team member do for this prototype? We all helped assemble the jigs together. Taking turns and doing each of the steps. Garret did the first jib and came up with the overall process. PHOTO Page 6