FRANC3D Training Workshop: Introduction to Fracture Mechanics & FRANC3D

Dive into the world of Fracture Mechanics and the powerful FRANC3D software. Join experts for a comprehensive training workshop covering theories, computational approaches, hands-on sessions, and more. Explore topics like crack analysis, fatigue life, and safe-life design philosophies.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

FRANC3D Training Workshop: Part I April - 2018 Drs. Paul Wash Wawrzynek, Bruce Carter, Tony Ingraffea and Omar Ibrahim Fracture Analysis Consultants, Inc.

Training Objectives General introduction to Fracture and FRANC3D: - capabilities and limitations Present theories and approaches to computational fracture mechanics implemented in FRANC3D Hands-on sessions give participants time to use software Opportunity for participants to ask questions and work on their own models 2 Part I

Workshop Agenda Part I: Introduction to Fracture Mechanics Analysis Part II: Introduction to FRANC3D Part III: Finite Element (FE) Model Import Part IV: Crack Insertion Part V: Static Crack Analysis & SIF Computation Part VI: SIFs from FE Analysis Part VII: Crack Growth Part VIII: Multiple/Variable DOF Approach to Fatigue Life Part IX: SIF History & Fatigue Life Part X: FRANC3D Files, Session Log, Command Line and Python Interface Part XI: Miscellaneous 3 Part I

Fatigue and Damage Tolerance Philosophies An important and challenging task for designers: to avoid failures. Part I

Fatigue and Damage Tolerance Philosophies Safe Life Design Fail Safe Design Damage Tolerance Design Future Trends in Fatigue Design 5 Part I

Safe Life Design Philosophy Products are designed to survive a specific design life Employed in critical systems that are either: Very difficult to repair or Cause severe damage to life and property if they fail Systems are designed to work for years without requiring repairs Treats fatigue as a crack nucleation process Does not explicitly consider the possibility for crack growth Until 1956, safe-life design concept was used to certify commercial aircraft designs 6 Part I

Safe Life Design Philosophy Prevent structural damage from developing Determine the life (based on testing and analysis) when a structural component (or complete structure) must be removed from service before critical damage limits are reached. Nearly always based on constant amplitude stress or strain ( or ) versus number-of-cycles (N) curves 7 Part I

Safe Life Design Philosophy Advantages: Does not (or should not) require in-service inspections Disadvantages: Even with built-in conservatism and large scatter factors, cracks and failure sometimes occur before the design safe-life is reached. Many (most) components are retired unnecessarily If cracking is discovered in-service, safe-life provides no information about the relative risk due to the damage. Does not account for in-service loads that differ from those considered during design. 8 Part I

Safe Life Design Philosophy USAF Bad Experiences with Safe-Life Early widespread cracking in C-5A lower wing structure Crash of F-111 in Dec. 1969 after only 107 flights The F-111 test program had demonstrated multiple lifetimes without failure. The lost F-111 contained a forging defect, which caused early cracking in this aircraft. F-111 C-5A 9 Part I

Safe Life Design Philosophy Comet 1 Aircraft Was certified as safe-life for 16,000 flights and 10 years in service There were two crashes in 1954 due to operational pressurization higher than that used in design at that time (8.25 psi vs 5 psi) Crashes of two Comet1 airplanes in 1954 led to the adoption of Fail-Safe design approach 10 Part I

Fail Safe Design Philosophy Consists of primary structural element and a redundant or backup structural element Fail-safe design is known as a redundant design or a multi-load path design Requires that if one element fails, the system does not fail Requires development of an inspection program capable of detecting fatigue cracks Recognizes that fatigue cracks might occur and structures are arranged so that cracks will not lead to failure of the structure before the cracks are detected and repaired 11 Part I

Fail Safe Design Philosophy Advantages: Able to manage the unexpected and mitigating damage if element failure occurs Disadvantages: Over-design will lead to overweight structure Difficult to accurately predict the failure modes of the structure 12 Part I

Fail Safe Design Philosophy Boeing 707-300 crashed in May 1977 The 707-300 airplane had been designed to a 'fail-safe' philosophy Crash was due to the horizontal stabilizer rear spar fatigue failure Inspections of the Boeing 707-300 fleet, made as a result of the crash, found another 38 aircraft with similar cracks This crash led to dropping fail-safe design and adopting damage tolerance design 13 Part I

Damage Tolerance Design Philosophy Linear elastic fracture mechanics approach (LEFM) is used to predict crack stability and crack growth FRANC3D is used for this type of prediction Requires inspections Objective is to assess the effect of cracks in the structure between two inspections 14 Part I

Damage Tolerance Design Philosophy Permits a structure to retain its structural strength for a period of use after it has sustained a given level of fatigue or accidental damage Knowledge of damage growth rates and residual strength is used to set inspection intervals Assumes that defects are already present at critical locations in new structures 15 Part I

Damage Tolerance Design Philosophy Components are qualified as: Non-inspectable: Inspectable: Safe-Life - with an initial in-service inspection. or Slow Crack Growth - cracks will not grow to a critical size over the service life Fail-Safe - multiple load paths or crack arrest mechanisms or Slow Crack Growth - crack will not grow to a critical size between inspections 16 Part I

Damage Tolerance Design Philosophy crack length at failure inspections crack size worse case crack scenario time of operation First inspection at 1/2 the worst case fatigue life 17 Part I

Damage Tolerance Design Philosophy Advantages: Healthy structures can be used indefinitely. Ease of model adaptation for new crack scenarios that may evolve in-service. Disadvantages: Cost of periodic inspections. Design approach has traditionally been deterministic and the life prediction estimate is dominated by: Choice of initial crack characteristics Assumed load spectrum. Multi-site and multi-element damage is not considered. LEFM does not accurately model small cracks. 18 Part I

Future Trends in Fatigue Design Probability-based analysis and assessment On-board structural health monitoring (sensors) Prognosis systems Digital twins 19 Part I

Introduction to Fracture Mechanics Analysis 20 Part I

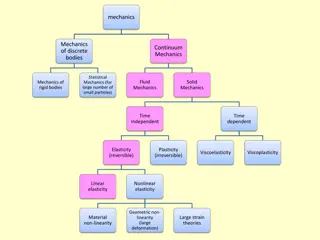

What is Fracture Mechanics? The classical objective of fracture mechanics is the determination of the rate of change of the shape of an existing crack. Will it propagate under given loading and environmental conditions, and, if it does propagate, at what rate, and into what configuration? The corresponding analyticalcomputational requirement has been to obtain the fields displacement, strain, stress, and energy from which the driving force for crack propagation might be extracted. The corresponding experimental requirement has been to measure the resisting force against crack propagation, and to observe and measure configuration change and rate of growth. 21 Part I

Linear Elastic Fracture Mechanics Review some basic elements of LEFM to prepare for computational implementation: Crack front stress and displacement fields Stress Intensity Factor T-stress Energy Release Rate 22 Part I

Continuum Fracture Modes y,v y,v y,v x,u x,u x,u z,w z,w z,w Mode II Mode III Mode I Basic modes of crack loading. Positive sense shown for each: Mode I = crack opening Mode II = in-plane sliding Mode III = anti-plane tearing 23 Part I

Crack Front Stress and Displacement Fields y y xy x r Williams (1957) expansion of crack tip stress and displacement fields: Mode I x = 0 z n n n n n n plane stress 1 = n + + I n n 2 ( ) 1 cos( ) 1 ( ) 1 cos( ) 3 r a 2 x 2 n 2 n 2 n 2 n 2 n = 1 ( ) = + v n 1 = n z x y + I n n 2 ( ) 1 cos( ) 1 ( ) 1 cos( ) 3 r a 2 y plane strain 2 2 2 2 2 = 1 n n n n n n 1 = n = = 0 + I n n ( ) 1 sin( ) 3 ( ) 1 sin( ) 1 r a 2 xy xz yz 2 2 2 2 2 = 1 n r n n n n 2 = n + + and where = G and = plane stress ( ) ( + ) plane strain I n n u a ( ) 1 cos cos( ) 2 2 2 2 2 2 = 1 n r n n n n 2 = n + I n n v a ( ) 1 sin sin( ) 2 2 2 2 2 2 = 1 24 Part I

Crack Front Stress and Displacement Fields y xy Williams expansion of crack tip stress and displacement fields (1957): Mode II = 2 2 1 n x r x n n n n n n 1 = = + 0 II n n 2 ( ) 1 sin( ) 1 ( ) 1 sin( ) 3 r a 2 x z 2 2 2 plane stress n n n n n n ( ) 1 = + + II n n plane strain = yz xz = + 2 ( ) 1 sin( ) 1 ( ) 1 sin( ) 3 r a v 2 y 2 2 2 2 2 z x y = 1 n n n n n n n 1 = n II n n ( ) 1 cos( ) 3 ( ) 1 cos( ) 1 r a 2 = 0 xy 2 2 2 2 2 = 1 n where = G and = plane stress ( ) ( + ) plane strain r n n n n 2 = + II n n u a ( ) 1 sin sin( ) 2 2 2 2 2 2 = 1 n n r n n n n 2 = n + + II n n v a ( ) 1 cos cos( ) 2 2 2 2 2 2 = 1 25 Part I

Crack Front Stress and Displacement Fields y y Example of Expansion Along Crack Line, x = r, Mode I x x (r) a = + + + + + 3 2 4 3 8 5 1 r a a r a r a r 2 3 4 5 x a = + + + 3 2 3 5 1 r a r a r 3 5 y First (leading), singular term, a1: contains the stress intensity factor Second term, a2: contains the T-stress Third term, a3: leading higher order term (note: non-polynomial!) 26 Part I

Definition of Stress Intensity Factor and T-stress from these Fields Neglecting all but the first, singular term of this stress field results in the formal definition of the stress intensity factor: = 2 lim r K r I yy 0 = 2 lim r K r II xy 0 = 2 lim r K r III yz 0 The T-stress is the constant stress acting parallel to the crack direction. 27 Part I

In Cylindrical Coordinates, to 2nd Term y T-stress 2 2 1 3 T ( ) = + 2 2 cos cos sin 1 cos K K I II 2 2 2 r 2 2 2 1 + 3 T ( ) = + + + 2 2 cos 1 sin sin 2 tan 1 cos K K K rr I II II 2 2 2 r 2 2 rcos 1 T KIsin + KII3cos 1 ( ) r = 2sin2 2 28 Part I

Mode III Fields, Plane Strain K K = = 12cos2 III r 12sin2 III r (22) ( ) ( ) yz xz 2 2 = = = = 0 x y z xz 12 2 K G r = sin2 w III = v = u 0 + =1 for plane stress, let 29 Part I

So Why is the Stress Intensity Factor so Important? Under conditions of small-scale yielding, all crack front fields are dominated (controlled) by the stress intensity factor. Therefore, all crack behavior: Stability will the crack tip move? Trajectory in what direction? Rate how fast? is controlled by the stress intensity factor and maybe T-stress 30 Part I

Concept of K-Dominance: When is LEFM Applicable? y K-Dominant Region KI 2 s = y x yld yield = + s y ns y y rp x D ns = + + / 3 2 3 5 ... a r a r 3 5 y Inelastic Region, Simplified If rp << D, KI still controls fracture process. 31 Part I

Energy Release Rate Recall that, in LEFM, energy release rate (crack driving force) is a dual of stress intensity. For example, in Mode I: 2 I K G = I ' E where = ' E E for plane stress E = ' E for plane strain 2 ( 1 ) We will first concentrate on computing stress intensity factors, then, later, energy release rates (and their derivatives!). 32 Part I

End Part I 33