Hazardous Energy Lockout/Tagout Essentials

Lockout/Tagout is crucial for preventing hazardous energy-related accidents in workplaces. This process involves blocking energy flow to equipment during maintenance, servicing, or repair to ensure safety. Learn about types of hazardous energy, lockout devices, energy isolating devices, and the importance of lockout measures through real-world case studies.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

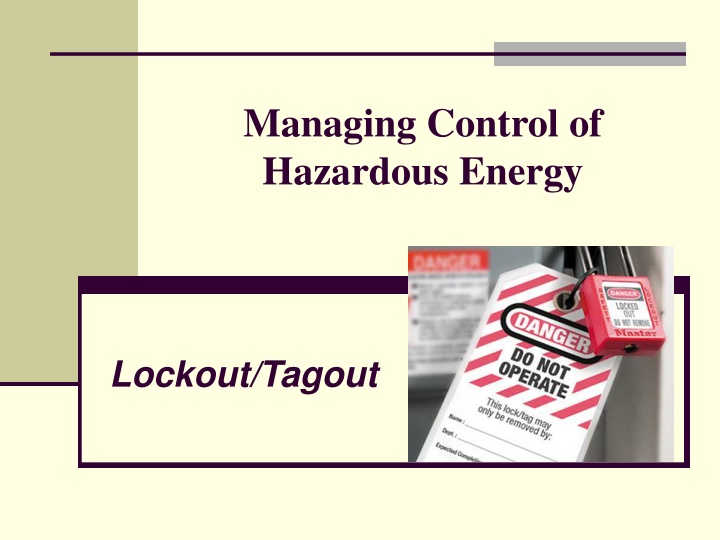

Managing Control of Hazardous Energy Lockout/Tagout

Lockout/Tagout Is the process of applying locks and tags to block the flow of hazardous energy from equipment or machinery so the equipment cannot start unexpectedly during servicing, maintenance or repair

Types of Hazardous Energy Electrical ( motors; lighting systems) Kinetic (moving equipment) Thermal (hot water, steam) Chemical (gases, liquids ) Potential Energy ( loaded spring)

Lock Out Devices Lockout devices can be a padlock, block or chain that are applied to energy isolating devices.

Energy Isolating Devices A device that physically prevents the transmission or release of an energy source to machinery or equipment. 180px-ElectricalPanel Typical energy isolating devices include switches,circuit breakers and valves.

Example: Hot Water Circulating Pump 2 Hazardous Energy Sources Thermal and Electrical H1 H2 3 lock out points (2 valves and one electrical switch) E1

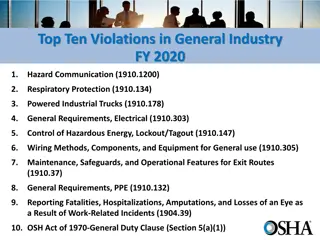

Why is Lockout Important? Prevents contact with equipment or machinery that could result in amputations, crushed limbs, electrocution, burns or death. Lock out tags It is a legal requirement under the Part 15 of the OHS Code -Managing Control of Hazardous Energy

Case Study # 1 A school maintenance worker with 23 years experience was removing obsolete wiring from a room beneath the football field grandstand. The wiring was located behind a 2400-volt transformer. In the process of removing the wiring, the worker contacted one of the wires to the transformer and later died from his injuries.

Case Study # 2 On June 2, 2005, a school district HVAC technician was accessing an electrical panel using a laptop computer to troubleshoot a problem with a mechanical cooling system. The technician was found collapsed on the floor in front of the high-voltage panel which was opened and energized with 110 to 600 volts of power.

Case Study # 2 Continued. The school board had procedures for locking out live power sources before performing maintenance work near electrical panels. However, these procedures did not detail in written form the hazards of working near live power and when personal protective equipment was required for work near live power. The School district was fined $100,000 for a violation of the Occupational Health and Safety Act that resulted in the death of an employee.

Employer Responsibilities The employer is responsible for establishing the lockout system to be implemented within the workplace. These procedures must be written. Employees must be provided with the proper training, tools and lock out devices.

Supervisor Responsibilities Supervisors must ensure that correct lockout procedures are in place and being followed at all times. Routine monitoring of operator lockout procedures should be conducted by supervisors.

Employee Responsibilities Locking out the energy isolating device before performing work. Removing their personal locks on the completion of their work. Keeping control of the keys to personal locks throughout the duration of the work.

When are Lockout Procedures Required? If removal or bypassing a guard or other safety device is necessary If place any part of body into a machine s point of operation or danger zone

When is Lockout Required? E.g., when doing maintenance or repairs on air handling equipment apply a lock to the electrical disconnect switch .

When is lockout not required? If electrical plug or switch is in immediate view & exclusive control of worker. No potential for release of hazardous energy once equipment is shut down. When work on energized equipment is necessary (an alternative safe work procedure required).

Lockout Procedure Identify machine/equipment and energy sources that need to be locked out. Notify all affected employees. Shut down equipment- ensure moving parts have come to a stop Identify and deactivate main energy isolating device for each energy source (e.g., disconnect switch; valve; circuit breaker etc.)

Lockout Procedure Cont. Release any stored energy. Apply the appropriate lockout/tagout device and personal lock to the energy isolating device. Test/verify lockout (ensure area is clear of personnel). Remove guards and perform work.

Removal of Lockout Reinstall guard and remove tools. Ensure other workers are in a safe location. Remove locks and tags- Except in emergencies, each device must be removed by the person who put it on. Notify affected employees. Restore power.

Applying Tagout Alone Can only be used if equipment cannot be locked out or if the employer can demonstrate that the tagout system will provide equivalent level of employee protection. Remember tags are warning devices. They do not provide the same physical control as a lock. Treat tags as if they were locks. . Lockout OSHA Tags

Special Situations Multiple point lockout Emergency lock Removal Multiple person lock out Servicing lasts longer than one shift. Contractors are performing service or maintenance at your workplace

Points to Remember Never loan/share your personal lock or key with anybody else. Use locks for lockout only- Keep control of keys to personal locks. Remove your lock on completion of the work. Locks may only be removed by the person who applied them. If emergency lock removal is required contact the your supervisor for authorization. Records of key codes to personal locks are kept with the supervisor or OHS Specialist.

Types of Lockout Securing Devices- Links Electrical Lockouts Circuit breaker Circuit Breaker Compact padlock Circuit breaker switch Universal wall switch Valve Lockouts (Gate and Ball Valves) Cable Lockouts Group Lockout Hasp

Video Links Overview of Lockout/Tagout Electrical Lock Out Devices Mechanical Lock Out Devices