HazCom 2012 Wrap-Up and Safety Requirements Overview

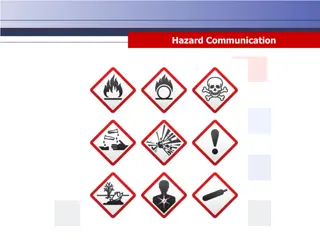

Discover the key aspects of hazard communication in 2012, including safety data sheets, labeling requirements, site-specific programs, and GHS adoption impact. Learn about chemical inventories, MSDS/SDS, pictograms, precautionary statements, and more. Explore revisions in NFPA standards and OSHA criteria related to flammable liquids. Gain insights into safety protocols for spray booths, exhaust ducts, and grounding of metal parts in hazardous environments.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

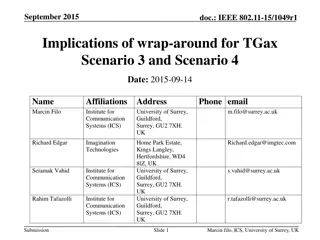

HazCom HazCom 2012 Summary and Wrap Up Summary and Wrap Up 2012

HAZARD COMMUNICATION REQUIREMENTS Site Specific Written Program Chemical Inventory MSDSs/SDSs Labeling Non-routine Tasks Contractors Training

Labels Product ID Signal word Hazard statement(s) Pictograms Precautionary statements Product & supplier identification filename -3

Safety Data Sheets (SDS) Section 1- Identification Section 9- Physical and Chemical Properties Section 10- Stability and Reactivity Section 11- Toxicological Information Section 12- Ecological Information (non-mandatory) Section 13- Disposal Considerations (non-mandatory) Section 14- Transportation Information (non-mandatory) Section 15- Regulatory Information (non-mandatory) Section 16- Other Information Section 2- Hazard(s) Identification Section 3- Composition/Information Ingredients Section 4- First-Aid Measures Section5- Fire-Fighting Measures Section 6- Accidental Release Measures Section 7- Handling and Storage Section 8-Exposure Controls/Personal Protective Equipment

Other Standard Revisions as a Result of GHS Adoption

1910.106 Revisions NFPA 30/Old OSHA 1910.106 Category Criteria 1 FP <23 C (73 F) BP 35 C (95 F) IA 2 FP <23 C (73 F) BP >35 C (95 F) IB FP 23 C (73 F) 60 C (140 F) 3 N/A IC, II FP >60 C (140 F) 93 C (200 F) 4 N/A IIIA - - 93 C (200 F) N/A IIIB

1910.106 Revisions (b)(2)(iv)(g) Flame arresters or venting devices required in paragraph (B)(2)(iv)(f) of this section may be omitted for Category 2 flammable liquids & Category 3 flammable liquids with flashpoint below 100 F (37.8 C) where conditions such that use may, in case of obstruction, results in tank damage.

1910.107 Revisions 1910.107(c)(9)(i) All metal parts of spray booths, exhaust ducts, & piping systems conveying flammable liquids or liquids with flashpoint 200 F (93 C) or aerated solids shall be properly electrically grounded in effective & permanent manner 1910.107(e) Flammable liquids & liquids with flashpoint >200 F (93 C)

1910.107 Revisions 1910.107(e)(4) Transferring liquids. Except as provided in paragraph (e)(5) of this section, withdrawal of flammable liquids & liquids with flashpoint >200 F (93 C) from containers having capacity >60 gal shall be by approved pumps. Withdrawal of flammable liquids or liquids with flashpoint >200 F (93 C) from containers & filling of containers

1910.107 Revisions 1910.107(e)(6)(iv) Piping systems conveying flammable liquids or liquids with flashpoint >200 F (93 C) shall be of steel 1910.107(e)(8) Pump relief. If flammable liquids or liquids with flashpoint >200 F (93 C) are supplied to spray nozzles by positive displacement pumps, pump discharge line shall be provided with approved relief valve

1910.107 Revisions 1910.107(e)(9) Grounding. Whenever flammable liquids or liquids with flashpoint >200 F (93 C) are transferred from one container to another, both containers shall be effectively bonded & grounded

1910.119 Revisions 1910.119(a)(1)(ii) Process which involves Category 1 flammable gas (defined in 1910.1200 (c)) or flammable liquid with flashpoint below 100 F (37.8 C) onsite in one location, in quantity of 10,000 pounds (4535.9 kg)

1910.120 Revisions 1910.120(a)(3) Health Hazard includes chemicals classified in accordance with 1910.1200, as posing one of the following hazardous effects: acute toxicity; skin corrosion or irritation; serious eye damage or eye irritation; respiratory or skin sensitization; germ cell mutagenicity; carcinogenicity; reproductive toxicity; specific target organ toxicity; aspiration toxicity or simple asphyxiant

1910.123-.125 Revisions Definitions 1910.124(c)(2) You must ensure that any exhaust air re-circulated from dipping or coating operation using flammable liquids or liquids with flashpoints >200 F (93 C) is:

1910.252 Revisions 1910.252(c)(1)(iv): minor language updates to assure compliance with Hazcom

Effective Completion Date Requirement(s) Who 12/1/13 Train employees on new label elements & SDS format Employers 6/1/15 Compliance with all modified provisions of this final rule, except: Chemical manufacturers, importers, distributors & employers 12/1/15 Distributors may ship products labeled by manufacturers under old system until 12/1/15 6/1/16 Update alternative workplace labeling & hazcom program as necessary, & provide additional employee training for newly identified physical or health hazards Employers Transition Period May comply with either 1910.1200 (final standard), current standard, or both Chemical manufacturers, importers, distributors & employers